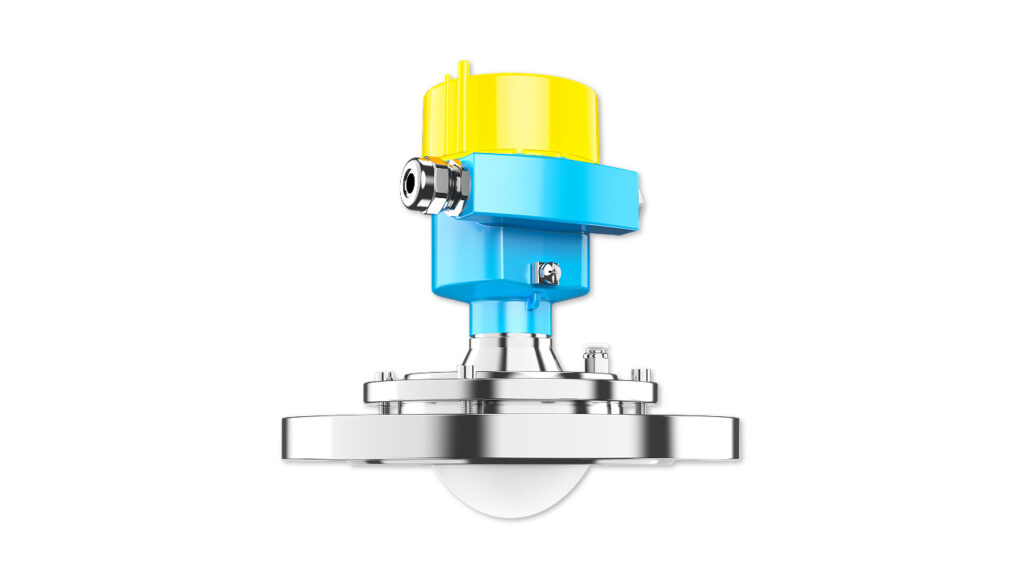

Pulp Tank Level Measurement Solution in Papermaking:JWrada®-35 Radar Level Transmitter

In the papermaking process, pulp tanks (such as pulping tanks and stock preparation tanks) are core process units that directly affect pulp uniformity and the stable material supply to downstream paper machines. The medium inside pulp tanks is typically a low-consistency slurry containing a large amount of floating fiber flocs, with thick foam often forming on the surface. Under conditions of high fiber content, heavy foam, and strong agitation, traditional level measurement technologies are prone to failure, resulting in unstable level control, pulp concentration fluctuations, and even production interruptions or equipment damage.

Leveraging years of technical expertise in level and point level measurement, Shenzhen Jiwei Automations Ltd provides a dedicated solution based on the JWrada®-35 radar level transmitter. Utilizing FMCW (Frequency-Modulated Continuous Wave) technology, the device effectively penetrates foam and suppresses agitation-induced disturbances, enabling continuous, accurate, and reliable level measurement in pulp tanks. This solution delivers robust automation support for safe and efficient papermaking operations.

Process Analysis — Level Measurement in Agitated Pulp Tanks

1. Typical Application in Agitated Pulp Tanks

Agitated pulp tanks play a critical role in papermaking processes by thoroughly mixing pulp, water, and chemical additives to produce a homogeneous slurry. The medium contains suspended fibers and generates significant foam during mixing. Stable level control is essential to ensure consistent material feeding to downstream paper machines and to maintain paper quality.

2. Medium Characteristics

The slurry inside agitated pulp tanks exhibits the following characteristics:

High fiber content: Floating fiber flocs with uneven density tend to adhere to sensor surfaces, causing sticking or false triggering in contact-based instruments.

Significant foam interference: Foam thickness varies with pulp concentration and agitation speed, leading to false responses in conventional level sensors.

Large viscosity variation: Changes in pulp consistency result in significant viscosity differences, making float-type or conductive sensors unstable.

Severe surface turbulence: High-speed agitation creates pronounced wave peaks and troughs, increasing measurement difficulty and destabilizing signals from ordinary radar or ultrasonic devices.

3. Automation Measurement Challenges

Under such typical agitated tank conditions, level measurement faces multiple challenges:

Fiber entanglement: Float switches or rotary paddle level switches are easily entangled by fibers, leading to sticking or malfunction.

Foam misdetection: Inconsistent foam layers may cause premature or delayed triggering, affecting control accuracy.

Surface turbulence interference: Strong agitation significantly disrupts measurement signals, reducing reliability.

Corrosion and abrasion: Chemical additives in pulp introduce corrosive effects that shorten the service life of metal sensors.

These challenges have long made level control in agitated pulp tanks a persistent issue for papermaking plants, directly impacting production efficiency and process stability.

2. Jiwei Radar Level Transmitter Solution

2.1 Instrument Selection

For complex pulp conditions, Jiwei recommends the JWrada®-35 radar level transmitter, featuring:

FMCW radar technology: Effectively penetrates foam and enables continuous level measurement, maintaining level fluctuation within ±3 mm.

Remote commissioning and diagnostics: Engineers can remotely view echo curves and EFT curves via the cloud platform, enabling rapid fault analysis and reduced downtime.

Corrosion-resistant design: Multiple antenna materials are available to ensure long-term stable operation in high-fiber and corrosive slurry environments.

Automation compatibility: Supports 4–20 mA + HART output and is also compatible with Modbus RTU/ASCII protocols, allowing direct integration into DCS, PLC, or SCADA systems for closed-loop control and remote monitoring.

2.2 Installation Arrangement

Top-center installation: The radar level transmitter should be installed at the center of the tank roof to avoid agitation interference and ensure continuous monitoring.

Safe clearance: Adequate distance should be maintained between the sensor and high-speed agitators to prevent mechanical collision or signal disturbance.

Auxiliary protection: Protective stilling pipes may be installed near the liquid surface when necessary to prevent direct foam impact on the antenna.

2.3 Software and Remote Commissioning Advantages

One of the core competitive strengths of JWrada® lies in its software system. The radar level transmitter offers unique software capabilities, including firmware updates, application-specific tuning, parameter configuration, and fault code diagnostics. Engineers can conduct one-to-one remote commissioning via a cloud server, viewing echo curves and EFT curves in real time for professional analysis. All these functions are independently developed by Jiwei, and currently have no equivalent solutions among domestic manufacturers.

Notably, JWrada® supports a cloud-based remote commissioning mechanism. Engineers collaborate directly with on-site personnel through the cloud platform, monitoring device operating status in real time and analyzing echo and EFT curves. More importantly, parameters and algorithms can be customized according to specific field conditions, ensuring optimal measurement performance for each individual installation.

3. Operational Performance and Results

In a practical application at a large papermaking enterprise in Huai’an, the JWrada®-35 radar level transmitter demonstrated stable and reliable performance:

Stable and continuous monitoring: Even under high-speed agitation, thick foam layers, and high fiber concentrations, the level signal remained continuous without false alarms or misoperation caused by foam or fibers.

Reduced on-site maintenance: Corrosion-resistant materials reduce cleaning frequency caused by fiber adhesion or corrosion, while remote diagnostics allow engineers to troubleshoot issues from the office without frequent site visits.

Controlled production process: Real-time level monitoring helps operators maintain continuous and uniform pulp supply, resulting in more stable feeding to downstream paper machines.

Improved operational safety: Reliable level monitoring enables timely alarms for low-level or near-overflow conditions, effectively preventing slurry overflow and equipment damage.

4. Technical Highlights

Software and data capabilities (core advantage):

The software system of JWrada® radar level transmitters represents its most significant competitive advantage. It supports firmware updates, application tuning, parameter configuration, and fault diagnostics. Through cloud-based remote commissioning, engineers can analyze echo and EFT curves in real time, perform algorithm optimization, and ensure optimal measurement performance under specific operating conditions, while significantly reducing on-site maintenance workload.

High reliability: Designed specifically for high-fiber and high-foam pulp tank applications, the system resists fiber entanglement and foam interference, delivering continuous and stable level signals to ensure process controllability.

Intelligent remote commissioning: Cloud-based collaborative commissioning supports parameter adjustment, application optimization, and fault troubleshooting, minimizing downtime and improving maintenance efficiency.

Corrosion and wear resistance: Constructed with 316L stainless steel, the transmitter offers excellent resistance to corrosion and abrasion, ensuring long-term stable operation in high-fiber, high-viscosity slurry environments containing chemical additives.

Strong automation compatibility: Supports 4–20 mA + HART output and Modbus RTU/ASCII protocols, enabling seamless integration into DCS, PLC, or SCADA systems for closed-loop control and remote monitoring.

5. Conclusion

Level measurement in papermaking pulp tanks faces long-standing challenges such as blocky pulp, fiber flocs, thick foam, floating fibers, and severe surface turbulence. Traditional sensors often suffer from interference, false operation, or frequent maintenance.

With FMCW radar technology, corrosion-resistant design, and cloud-based remote commissioning capabilities, the JWrada®-35 radar level transmitter achieves continuous and stable level monitoring and allows customized parameter optimization based on actual field conditions. This solution reduces maintenance requirements, improves process visibility, and ensures safe and continuous production.

This application case fully demonstrates the reliability and practical value of Jiwei radar level transmitters in complex pulp level measurement scenarios, providing a proven reference solution for the papermaking industry and other high-interference industrial level measurement applications.