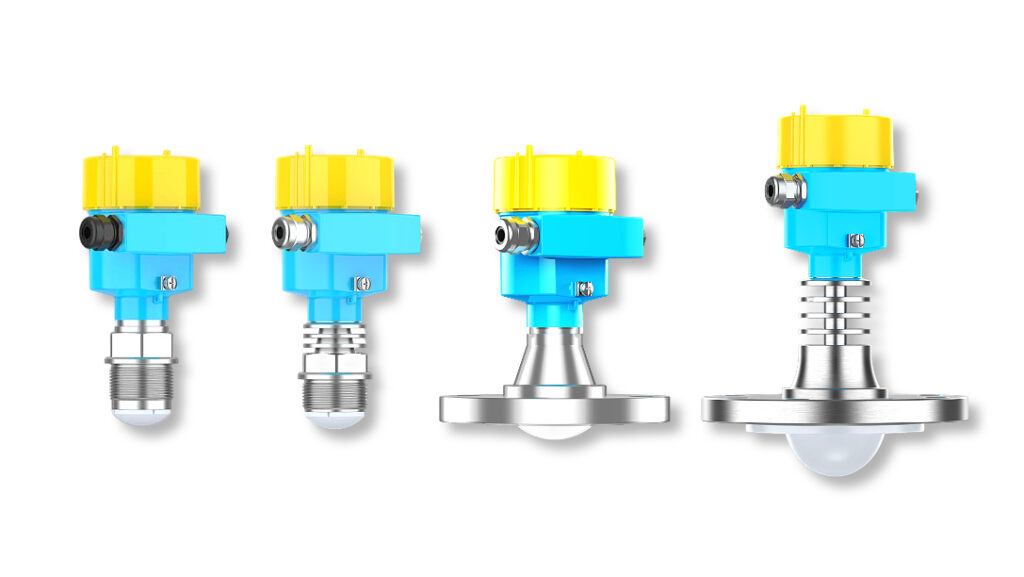

Smart Radar Level Meter for Pharmaceutical Tanks

Introduction

In modern pharmaceutical production, precise liquid level monitoring is essential to ensure process safety, equipment reliability, and consistent product quality. Liquid levels directly impact the operation of dosing pumps, mixers, and chemical transfer systems. In critical areas such as reagent dosing tanks, wastewater treatment tanks, and formulation storage tanks, abnormal levels can lead to pump dry-running, overflow, or chemical spillage, posing safety risks and potential contamination.

At a pharmaceutical facility in Huai’an, Jiangsu, Shenzhen Jiwei Automations Ltd.’s radar level meters were successfully applied to multiple reagent and storage tanks, enabling real-time level monitoring and automated control. The radar level meters feature high reliability, corrosion resistance, and intelligent interlock control, automatically activating or stopping pumps and dosing systems based on liquid level changes. Their stable performance and flexible installation make them the ideal solution for liquid level management in pharmaceutical production, ensuring safety, protecting equipment, and supporting efficient operations.

1. Product Specifications and Technical Features

Based on the plant’s process requirements, Jiwei radar level meters demonstrated multiple advantages. Prior to installation, the project team held multiple technical discussions with operators and process engineers to confirm liquid types, tank depth, and mixer arrangements, ensuring probe lengths and installation methods met process needs:

Power Supply & Signal Output

The radar level meters use DC24V power and 4–20mA signal output, seamlessly integrating with PLC, SCADA, or DCS systems for real-time monitoring and remote data collection.

Measuring Range & Accuracy

These meters cover a 0–7m range, suitable for pharmaceutical reagent and formulation tanks. High-precision radar detection provides accurate liquid height measurement, even in conditions with foam, vapor, or gas.

Corrosion-Resistant Design

Probes are made from acid- and alkali-resistant materials, with corrosion-resistant cables up to 50m long, suitable for pharmaceutical chemicals and cleaning solutions, ensuring long-term stable operation.

Flexible Installation

Supports both submersible and top-mounted installations. Installation height is adjustable via fixed columns and manual winches. Top-mounted probes are designed to avoid interference with mixers or agitators, adapting to diverse tank layouts.

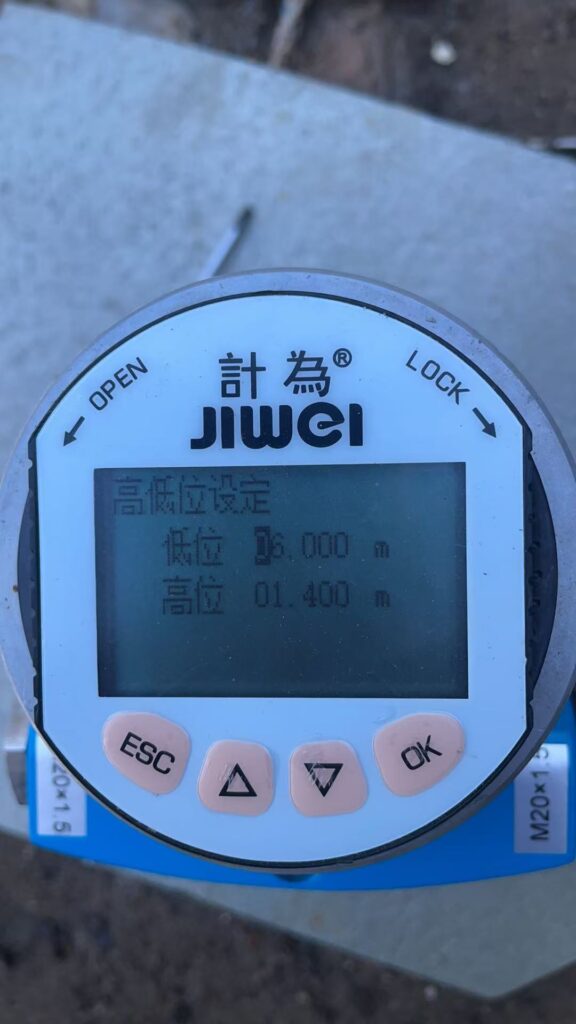

Intelligent Interlock Control

Radar level meters can automatically interlock with dosing pumps or mixers. When liquid levels reach set thresholds, pumps or mixers start or stop automatically, keeping levels within safe ranges and preventing process interruptions.

Through close collaboration with the process department, the radar level meters completed system deployment, enhancing operational safety and efficiency.

2. Installation and On-Site Considerations

During installation, the following points are critical:

Lightning Protection Grounding

All metal equipment, including mixers and aerators, must be properly grounded (resistance ≤ 4Ω) to ensure personnel and equipment safety.

Reserved Installation Conduits

Tank walls should include conduit interfaces for radar probes, pH meters, or other instrumentation to avoid structural damage during future modifications and ensure stable probe placement.

On-Site Calibration and Maintenance

Probe length and installation height should match tank depth, liquid properties, and mixer positions. Jiwei radar level meters include auto-diagnostics, alerting for fouling or abnormal conditions and enabling intelligent maintenance.

3. Typical Pharmaceutical Applications

1. Reagent Dosing Tank Monitoring and Control

Radar level meters provide real-time liquid level data and automatically control dosing pumps at upper and lower thresholds. Corrosion-resistant probes withstand acidic or alkaline reagents, and cables up to 50m allow remote monitoring and centralized management.

2. Wastewater Treatment Pump Interlock

During pharmaceutical wastewater treatment, the meters interlock with lift pumps, starting automatically when levels are low and stopping when levels reach set points, maintaining process continuity and reducing manual intervention.

3. Mixing Tank Level and Equipment Safety

In mixing tanks for formulations, radar level meters provide precise measurements and avoid interference with agitators. Automatic interlock ensures pumps or mixers operate only when liquid levels are within safe ranges, preventing overflow or dry-running.

4. Storage Tank Level Management

For chemical or formulation storage tanks, corrosion-resistant probes and accurate measurement enable remote monitoring and alerts, reducing chemical spillage risk and ensuring production safety.

4. Brand Compatibility and Customization

Jiwei radar level meters are compatible with mainstream automation brands such as CNNC Instruments, Leici, and LianCe, allowing easy integration into existing platforms. They support multiple specifications to fit various tank sizes, chemical properties, and process requirements. In practice, the meters interlock with dosing systems and pumps for automatic level control, preventing overflows or dry-running, reducing human intervention, and improving operational efficiency. Their stable performance and intelligent interlock make them the preferred solution for liquid level monitoring in pharmaceutical production.

Subheading for Image:

Corrosion-Resistant and Intelligent: Jiwei Radar Level Meters Safeguard Pharmaceutical Tank Operations

5. Conclusion

Jiwei radar level meters provide reliable, corrosion-resistant, and intelligently controlled liquid level monitoring for pharmaceutical production. Applicable to reagent dosing tanks, wastewater treatment tanks, mixing tanks, and storage tanks, they enable real-time monitoring, automatic pump/mixer interlock, reduce manual intervention, and ensure safe and stable operations.

By deploying Jiwei radar level meters, pharmaceutical facilities achieve visualized and remote level management, enhancing operational efficiency, production safety, and maintenance management, while reducing labor and operational risks.