Can Gear Reducers Use Level Switches? — Ensuring Reliable Lubrication Monitoring

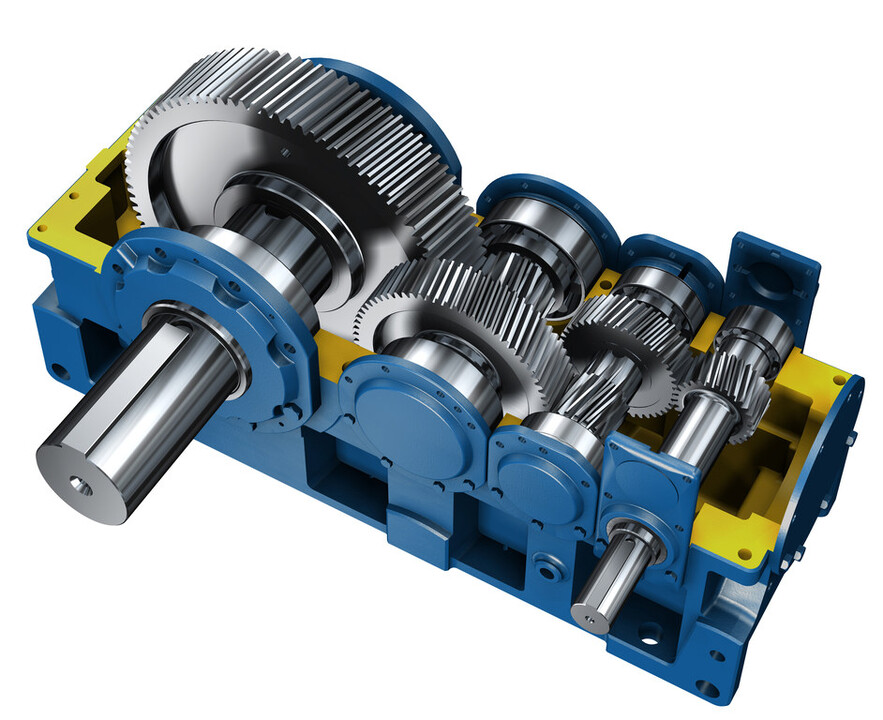

In industrial production sites, gear reducers are almost everywhere.

As an indispensable part of power transmission systems, they are widely used in conveying, stirring, lifting, and compression equipment.

During long-term operation, the health of a gear reducer largely depends on one seemingly insignificant factor — the lubrication oil level.

If the oil level is too low, the gears and bearings cannot be properly lubricated, causing friction, rising temperatures, and even severe failures or shutdowns. If the oil level is too high, it may lead to oil churning, excessive heat, seal leakage, or poor venting.

Therefore, real-time monitoring and alarming of the lubrication oil level are essential to ensure stable and reliable operation of gear reducers. A simple, reliable, and cost-effective way to achieve this goal is — using a level switch.

1. Why It’s Reasonable to Install a Level Switch on a Gear Reducer

A gear reducer typically includes an independent oil chamber or reservoir for lubrication oil storage.

Traditionally, operators rely on manual inspection, observing the oil level through a sight glass or dipstick.

However, this method has several limitations:

- Low inspection frequency: Oil leaks or evaporation due to high temperatures might not be noticed in time.

- No remote monitoring: There’s no automatic alarm or interlock stop function.

- High maintenance risk: Frequent opening for inspection may introduce dust or moisture, contaminating the oil.

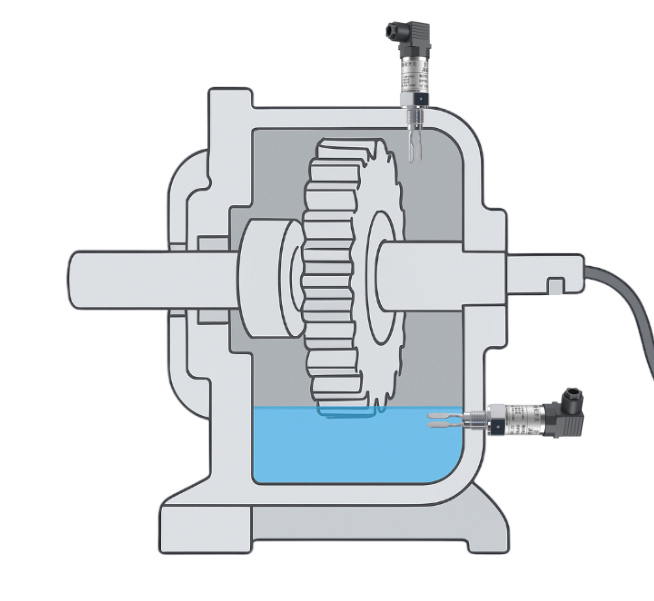

By contrast, a level switch can be easily installed on the sidewall of the oil chamber without structural changes.

It continuously monitors the oil level in real time, outputting a signal when the level exceeds or drops below the set point — triggering an alarm or protective shutdown.

This monitoring method is fast, maintenance-free, and cost-efficient — perfectly meeting the safety requirements of gear reducer operation.

Installing a level switch in the lubrication system is not only reasonable but also a high-value, reliable improvement.

2. Installation Positions and Control Logic

Typical installation methods for level switches in gear reducers include:

- Low-level alarm point:

Mounted at the minimum safe oil level position. When the oil drops below this point, the switch activates, sending a signal for refilling or automatic shutdown. - High-level alarm point:

Mounted at the maximum allowable oil level, preventing overfilling that may cause oil seal leakage or venting issues. - Dual-point control:

Using two level switches — one high, one low — to achieve automatic control through PLC: “Start filling at low level, stop at high level,” keeping the oil level constant.

For large or critical gear reducers, dual-point control is recommended to minimize manual intervention and ensure automatic lubrication management.

3. Which Type of Level Switch Is the Best Fit?

✅ Vibrating Fork Level Switch (Recommended Type)

Installation position of a mini-type vibrating fork switch in a gear reducer

Lubrication oil in gear reducers typically has medium-to-high viscosity, is subject to mild vibration, and often operates at elevated temperatures.

Conventional float or electrode-type level detectors are prone to malfunction under these conditions, as oil properties affect their accuracy.

By contrast, vibrating fork level switches stand out with exceptional reliability and stability in such environments.

Inside the switch, a piezoelectric crystal drives the fork to vibrate continuously.

When the fork is in air, its resonance frequency remains high; once it touches the oil, the liquid’s density and viscosity dampen the vibration.

This frequency shift is detected by the internal circuit, which then outputs a clear ON/OFF signal — accurately determining “liquid present” or “no liquid.”

This purely mechanical vibration-based principle makes it immune to the effects of conductivity, dielectric constant, or reflection, ensuring stable operation across all types of oil media.

Ring-21 Vibrating Fork Level Switch (Mini Type)

📈 Main Advantages

- Wide applicability

Suitable for gear oil, hydraulic oil, lubricating grease, and other oil-based media; also ideal for high-viscosity liquids such as heat transfer oil, heavy oil, and compressor lubricants. - Unaffected by medium properties

Works equally well in thin or highly viscous oils; unaffected by bubbles or mild emulsification. - Flexible installation

Can be installed horizontally or vertically, ideal for confined reducer housings.

Supports thread or flange connections for easy retrofit or replacement of old sensors. - Maintenance-free and long service life

No moving parts, no mechanical wear. The fork is coated to resist oil buildup and remain responsive even in hot, viscous oil. - High reliability

Built-in temperature compensation and self-diagnosis automatically detect signal drift or sensor contamination and provide fault alerts, ensuring continuous stability.

🔧 Performance in Real Applications

Taking Shenzhen Jiwei Automations Ltd.’s Ring-21 Vibrating Fork Level Switch as an example,

this series has been successfully applied in multiple heavy machinery, metallurgical equipment, and gear reducer manufacturing plants across China.

Ring-21 Vibrating Fork Level Switch in Gear Reducer Lubrication Monitoring

In one large planetary gear reducer project, the customer previously used a mechanical float switch for oil monitoring.

Due to high oil temperature and sludge buildup, the float often moved sluggishly or jammed, causing delayed oil level alarms and repeated overheating shutdowns.

To solve this, the customer replaced it with a Jiwei Ring-21 vibrating fork level switch, directly installed on the sidewall of the oil chamber.

Once powered, it continuously monitors the oil level in real time.

When the level drops below the preset threshold, the system immediately triggers a low-level alarm and interlocks shutdown, effectively preventing lubrication failure.

After six months of continuous operation:

- Oil level alarm accuracy reached 100%;

- All shutdowns caused by oil level faults were eliminated;

- Maintenance intervals extended from once per month to once every three months;

- Oil seal leakage incidents significantly decreased.

Operators reported:

“We used to worry about unstable oil levels. Now the system monitors automatically and alarms in time — almost no manual intervention needed.”

4. Field Application Example

On a heavy machinery production line, multiple large planetary gear reducers operate under heavy load.

In the past, lack of real-time oil level monitoring often led to gearbox overheating and abnormal noise.

Maintenance staff relied on periodic inspection, which was time-consuming and unreliable.

The company later installed two Jiwei Ring-21 vibrating fork level switches on each reducer — one for high-level, one for low-level alarm.

When the oil drops below the threshold, the system immediately triggers both sound and light alarms and shuts down automatically to prevent dry running.

After six months of operation:

- Shutdowns caused by oil level faults dropped from three per month to zero;

- Maintenance intervals increased by about 40%;

- Internal gearbox temperature remained stable, and oil change intervals were extended.

Operators noted:

“We used to rely on experience and sight glasses. Now the alarm tells us instantly — safer and more reliable.”

5. Additional Benefits of Using a Level Switch

Beyond accident prevention, a level switch in a gear reducer offers additional advantages:

- Remote monitoring: Level status can be integrated into PLC or DCS systems for centralized supervision and logging.

- Predictive maintenance: Oil level fluctuations may indicate leaks, evaporation, or abnormal temperature trends — enabling early intervention.

- Enhanced reliability: Stable oil management extends the life of gears and bearings, reducing unexpected downtime.

6. Conclusion

As industrial automation and intelligent maintenance advance, lubrication management of gear reducers is shifting from manual inspection to smart monitoring.

With its simple structure, fast response, maintenance-free design, and high reliability,

the vibrating fork level switch has become one of the most practical and effective devices for lubrication oil monitoring in gear reducers.

Whether in heavy machinery, metallurgy, mining, food processing, chemical, or conveying industries —

wherever there’s a lubrication system in a gear reducer, it’s worth installing a reliable level switch to ensure long-term, safe, and efficient operation.

A tiny switch signal can make the difference between smooth running and costly failure.