Study on the Impact of Steam, Dust, and Bubble Environments on Radar Level Meter Range Performance

Abstract

Radar level meters, as critical non-contact liquid level measurement devices in modern industrial process control, often experience range performance degradation due to environmental interferences under complex operating conditions. Based on beam attenuation models and Mie scattering theory, this paper systematically analyzes the impact mechanisms of three typical environments—steam, dust, and bubbles—on radar level meter range. It discusses performance differences at different frequencies (26GHz and 80GHz) and proposes engineering countermeasures to optimize measurement accuracy and stability, providing theoretical support and practical guidance for designing high-reliability level measurement systems.

Introduction

Radar level meters utilize the time-domain reflection characteristics of electromagnetic waves to achieve non-contact level measurement, widely used in chemical, pharmaceutical, energy, and food industries. However, environments containing steam, dust, and bubbles cause varying degrees of electromagnetic wave scattering, absorption, and multipath reflection, leading to signal attenuation and false echoes, which impair measurement stability and maximum range. High-frequency radar level meters (such as 80GHz), with shorter wavelengths and narrower beam widths, are more susceptible to Mie scattering caused by particulate interference, notably in vapor tanks, evaporators, and cement silos.

1. Impact of Steam Environment on Radar Signal Propagation

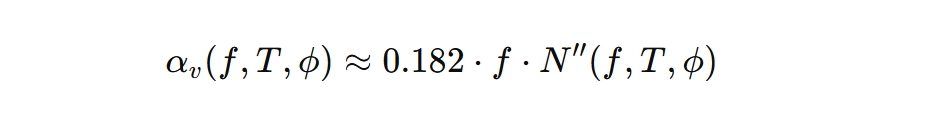

In high-temperature and high-humidity conditions, steam acts as a dielectric lossy medium causing radar wave attenuation, especially in the microwave band. According to the ITU-R model, the attenuation coefficient α_v (dB/m) of steam can be approximately expressed as:

where f is frequency (GHz), T temperature (K), φ relative humidity, and N” dielectric loss factor.

At 80GHz, the high-frequency signal penetration through saturated steam zones suffers greater attenuation than at 26GHz, significantly degrading range performance. Experiments indicate that at saturated steam temperatures above 100°C and relative humidity exceeding 95%, 80GHz radar echo energy decreases by over 40%.

Engineering Recommendations:

- Use radar meters with dynamic gain compensation.

- Install sensors away from steam outlets to avoid high-density steam zones.

- Employ nitrogen purging to prevent lens condensation and water droplet adherence.

2. Mie Scattering Mechanism and Signal Attenuation in Dust Environments

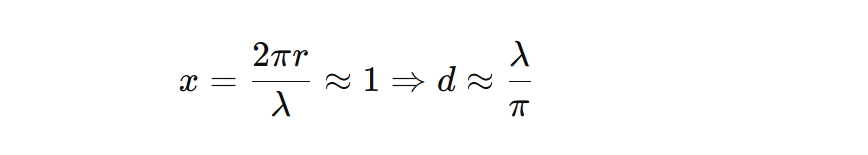

In solid material silos handling cement, flour, or coal powder, radar signals passing through dust zones are attenuated by combined Mie scattering and absorption effects. The attenuation depends on particle diameter d, relative permittivity ε, and concentration C.

According to Mie theory, scattering intensity peaks when particle size matches the radar wavelength. For 80GHz radar (λ≈3.75mm), dust particle sizes in the 0.5–1.5mm range cause the strongest scattering. In industrial silos with dust concentrations above 50mg/m³, the main echo signal weakens significantly, leading to echo loss and range shortening.

Engineering Recommendations:

- Prefer 80GHz radar with dynamic beam angle optimization.

- Set blind zones or delay measurement during high dust generation periods.

- Use dust removal devices or isolation sleeves to reduce antenna contamination and multipath reflections.

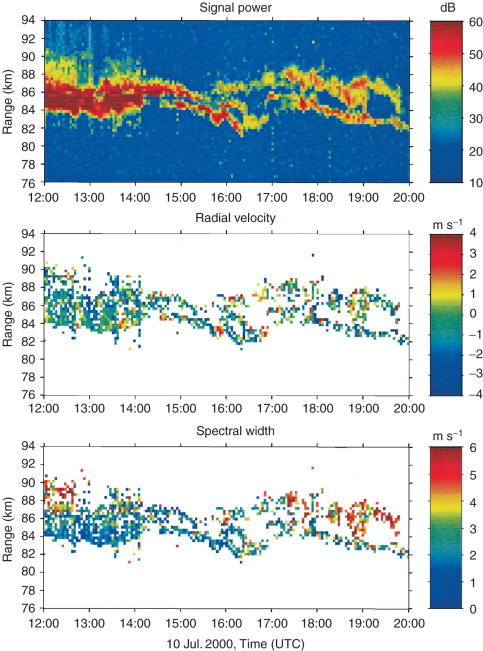

3. Impact of Bubble Interference on Liquid Surface Echo Stability

In fermentation tanks, condensers, and foam reactors, bubbles generated by stirring, heating, or gas injection create dense reflective interfaces that cause multipath interference and signal drift.

When bubble layer thickness exceeds half the radar wavelength, the original liquid surface reflection is disturbed. Radar systems often mistake the bubble top layer for the liquid surface, causing false high alarms and unstable readings.

Engineering Recommendations:

- Use high-frequency radar level meters with intelligent echo recognition algorithms to filter false echoes.

- Deploy redundant measurements combining hydrostatic pressure sensors or guided wave radar.

- Install defoamers or set delay filters to mitigate short-term disturbances.

4. Field Interference Case Studies

At a petrochemical dehydration tower, 80GHz radar level meters experienced fluctuating readings due to direct steam jet interference. Adjusting installation angles and using air purging stabilized the signals.

At a cement plant clinker silo, radar signals were lost during initial material loading because of sudden dust concentration increases and enhanced Mie scattering. Setting blind zones and delayed measurement effectively mitigated interference.

Conclusion

Steam, dust, and bubbles are the most common interference sources affecting radar level meter range in industrial applications. This study integrates physical models with Mie scattering and dielectric loss theories to systematically analyze their effects on radar signal propagation. Effective radar selection and installation require careful consideration of operating frequency, antenna design, and signal processing capabilities, along with engineering countermeasures such as optimized installation, blind zone configuration, and intelligent algorithms. Future research should focus on multi-sensor fusion and AI-assisted identification to enhance radar level meter reliability in extreme and complex environments.