How to Test a Tuning Fork Level Switch?90% People Get It Wrong!

Why Testing a Tuning Fork Level Switch Matters

In industries like chemical processing, pharmaceuticals, food & beverage, and energy, accurate level control is essential for safety and efficiency. Tuning fork level switches are widely used for overflow protection, pump control, and interlock safety loops due to their simplicity and reliability.

However, incorrect testing can lead to:

- Measurement errors or permanent sensor damage.

- Safety hazards in explosive environments where interlocks fail.

- High operational costs from downtime and unplanned maintenance.

According to IEC 61508 functional safety standards, regular proof testing of level switches is mandatory for safety integrity level (SIL) compliance. Testing must be carried out using approved methods to ensure system integrity.

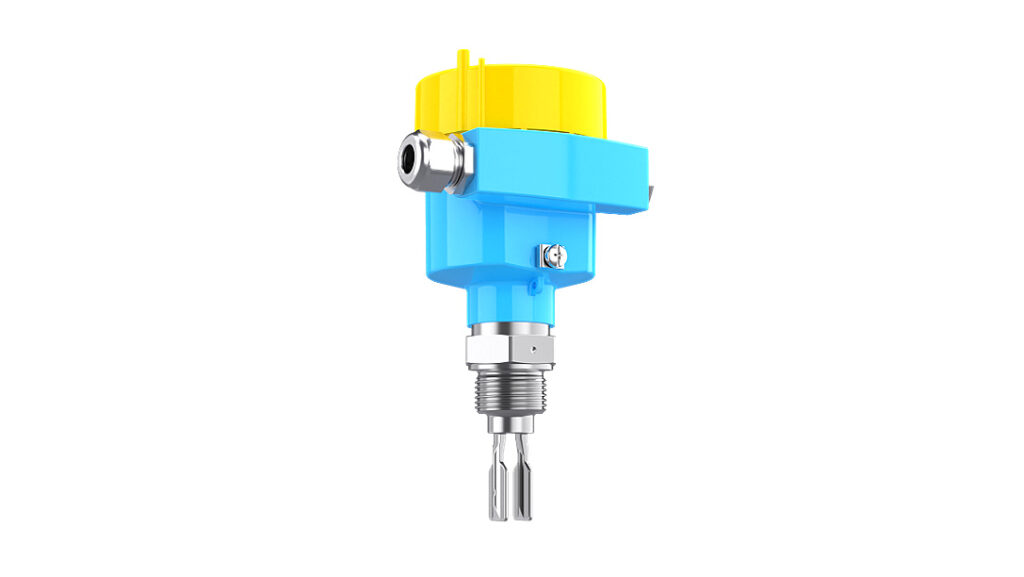

How a Tuning Fork Level Switch Works

The principle behind a tuning fork level switch is simple yet highly effective: detecting frequency change due to liquid contact.

- In air: The fork vibrates at its natural resonance frequency, and the electronics interpret this as a “dry” signal.

- In liquid: Vibration slows down due to damping, which triggers a “wet” signal.

Why this technology is reliable:

- Not affected by dielectric constant or foam.

- No calibration required—plug and play.

- Compliant with SIL2/SIL3 safety applications and explosion-proof standards.

How to Quickly Test a Tuning Fork Level Switch

The recommended and safest method for acceptance or maintenance testing is the clean water immersion test.

Step-by-Step Procedure:

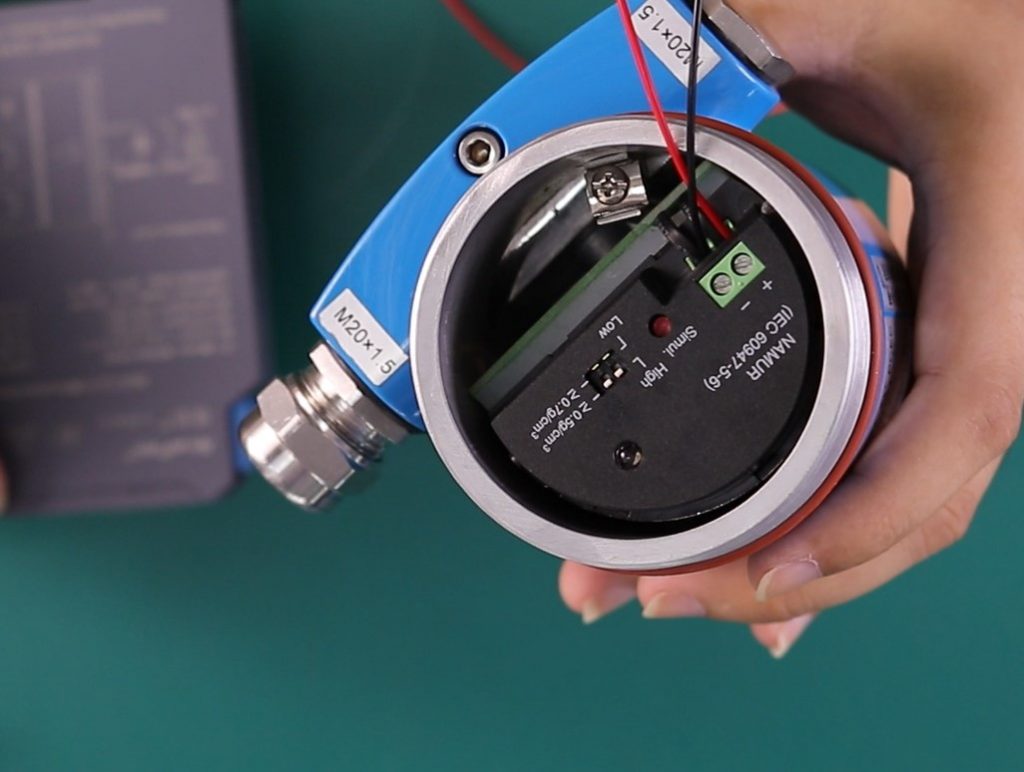

- Ensure the switch is properly wired and powered.

- Slowly immerse the fork into clean water.

- Observe whether the indicator LED or output signal changes state (e.g., from “dry” to “wet”).

- Remove the fork and confirm that the signal returns to its original state.

If both transitions occur correctly, the device is functioning as expected.

For advanced checks, verify the relay or NAMUR signal output in the control system, especially when the switch is part of a safety interlock loop. This ensures the valve or pump responds correctly.

Common Mistakes and Why They Are Dangerous

Unfortunately, some technicians still use incorrect methods that can damage the device:

Tapping the fork with a hand or tool

This creates mechanical shock, damaging the internal crystal and reducing accuracy.

Striking the fork with hard objects

Even worse, this can cause the fork to break or compromise explosion-proof sealing.

Simulating signals improperly

Injecting fake electrical signals can burn the electronics if not done correctly by trained personnel.

Bottom line: Never tap, hit, or force signal simulation without proper tools. The only correct method is liquid immersion testing.

Best Practices for Acceptance and Maintenance

While tuning fork level switches require minimal calibration, regular proof tests are essential, especially in SIL-rated safety systems. Recommended practices include:

- Perform water immersion testing after every maintenance or shutdown.

- Log response times and signal changes for compliance documentation.

- Conduct interlock verification to ensure pumps or valves operate correctly.

- Follow testing requirements for hazardous areas.

Why Upgrade from Glass Tube Level Gauges to Tuning Fork Switches

Many plants still rely on glass tube level gauges, which only provide visual indication without automatic control. In hazardous environments, this is a major safety gap.

Adding a tuning fork level switch allows:

- Automatic detection of high or low levels.

- Interlock control to start or stop pumps automatically.

- Enhanced explosion safety by minimizing human intervention.

In short, “Don’t just monitor—control.” Moving from “can see” to “can control” is the key to modern process safety.

Conclusion: The Right Test for Reliable Safety

Testing a tuning fork level switch may seem simple, but using the wrong method can cause major issues. Remember:

- Do this: Water immersion testing + signal verification.

- Avoid this: Hitting the fork or forcing electronic simulation.

- Always: Integrate the test into your functional safety plan (SIL verification).

When combined with proper automation and interlocks, a tuning fork level switch ensures reliable, safe, and cost-effective level control in critical applications.