Wet Gypsum Stockpile Level Monitoring: Why More Power Plants Are Choosing Radar Level Meters

In the environmental control systems of coal-fired power plants, the large amount of gypsum generated during wet flue gas desulfurization usually needs to be stored in centralized stockpiles, awaiting subsequent transport or reuse. With continuously changing production volumes, companies must have real-time knowledge of gypsum height and inventory in the stockpile. Otherwise, this can not only affect transportation planning but also put pressure on on-site operational management.

Therefore, establishing a stable, long-term level monitoring solution has become a key part of wet gypsum management.

Why Is Wet Gypsum Measurement More Challenging?

Compared to most dry, free-flowing bulk materials, wet gypsum usually exhibits a special state somewhere between solid and semi-solid. This material neither flows as easily as powders nor has a stable liquid surface. Its physical properties fluctuate with process conditions, placing higher demands on level measurement. In practice, the main measurement challenges include:

- High viscosity and adhesion: Wet gypsum tends to form a layer of material on probes or equipment surfaces. Over time, this can cause coating buildup, affecting instrument sensitivity and measurement reliability.

- Variable moisture content: Depending on dehydration efficiency or process stage, gypsum moisture content can change, altering its density, flowability, and pile shape.

- Temperature-related effects: Temperature influences material adhesion and may affect clumping, creating uncertainties for on-site measurement conditions.

- Presence of dust and moisture: During storage and transport, fine particles may generate dust, and high humidity increases adhesion risk. This complex environment poses a long-term challenge to instrument stability.

- Continuously changing pile shape: As the conveyor system continuously adds or removes material, pile height and surface structure change dynamically, sometimes forming irregular surfaces or local collapses, which requires stable measurement signal acquisition.

Overall, these factors combine to make wet gypsum conditions complex, testing instruments for long-term stability, anti-interference ability, and maintenance control. Therefore, during solution selection, it is usually necessary to prioritize measurement technologies that can adapt to changing material conditions and possess strong environmental resilience.

Practical Use of Contact Level Switches

In some projects, vibrating or rotary paddle level switches are still used for high-level alarms. However, engineering experience shows that when dealing with high-moisture, adhesive gypsum, a key practical issue arises: probes may experience material buildup or coating. Once the coating thickens, it can lead to:

- Reduced sensitivity

- Delayed response

- Increased risk of false alarms

Thus, in such conditions, equipment often requires regular inspection or cleaning to maintain proper operation. It is important to note: whether material buildup occurs depends on viscosity, moisture content, and on-site temperature conditions, which may vary significantly between power plants.

This is why more and more engineers are reevaluating measurement technology approaches.

Engineering Advantages of Non-Contact Radar

Compared with traditional contact level switches, radar level meters use electromagnetic waves for non-contact measurement, showing significant reliability and stability in wet gypsum conditions. Their main advantages include:

✅ Remote monitoring and maintenance

Supports cloud platforms or network remote access, allowing engineers to view echo curves, diagnostic status, and adjust parameters remotely, reducing on-site operation and improving maintenance efficiency.

✅ Unaffected by material adhesion

Since radar probes do not contact the gypsum directly, measurement errors caused by buildup or sticking are avoided, reducing measurement risk at the source.

✅ Insensitive to material condition changes

Regardless of fluctuations in humidity, viscosity, or temperature, the radar measurement principle remains stable, continuously providing accurate level data.

✅ Reduced maintenance requirements

Non-contact measurement significantly decreases the frequency of manual cleaning and on-site inspections, lowering operational costs.

✅ Supports continuous measurement

Unlike contact devices that provide only switch-type alarms, radar can output continuous level signals, supporting inventory management and transport scheduling with real-time data.

✅ Adaptable to large stockpiles

Radar’s long-range measurement capability ensures reliable performance even in high stockpiles or large-span storage facilities.

For power plants pursuing long-term stable operation and efficient maintenance, these features make radar level meters the ideal choice for wet gypsum storage management.

Software-Enabled Radar Solutions for Complex Conditions

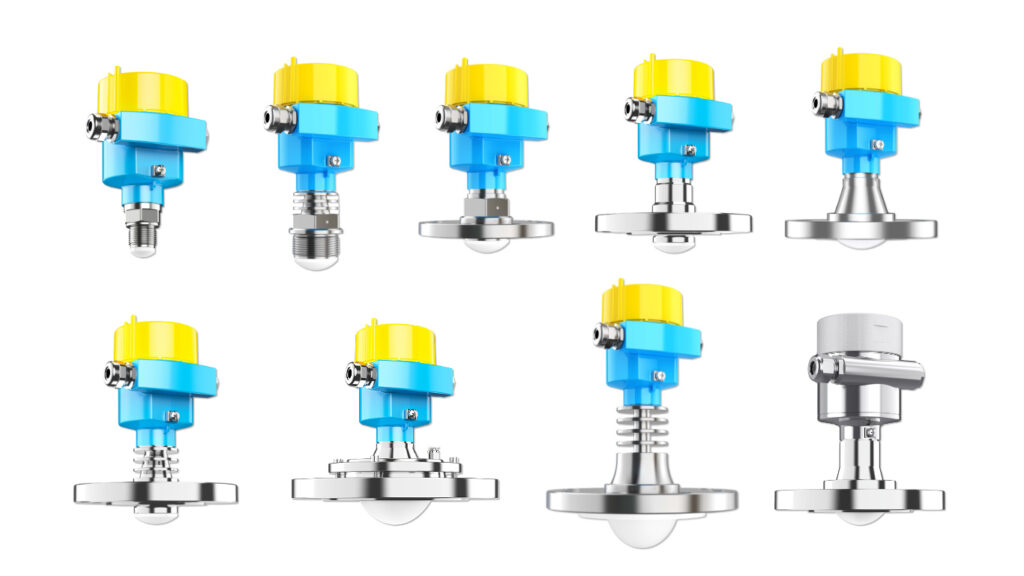

Jiwei JWrada® radar level meters not only emphasize reliability in hardware design but also demonstrate significant advantages in software functions and intelligent operation, making them particularly suitable for complex and demanding wet gypsum stockpile environments.

These devices support advanced features, including:

- Firmware upgrades: Users can update system firmware according to on-site conditions, ensuring instruments maintain the latest performance and functionality.

- Remote parameter configuration: Engineers can remotely set range, alarm points, and signal filtering parameters via network or cloud platforms without frequent on-site operations.

- Diagnostic information access: Real-time monitoring of device status, including signal quality, hardware health, and potential fault warnings, providing a scientific basis for maintenance.

- Echo and EFT curve analysis: Engineers can gain in-depth understanding of material surface characteristics and pile dynamics through echo and EFT curve analysis, supporting algorithm optimization.

With cloud platforms and remote commissioning, engineers can collaborate with on-site personnel for real-time guidance. Adjusting probe positions, optimizing echo signal processing, or fine-tuning parameters for humidity, viscosity, or temperature variations can all be done quickly without shutdowns or on-site intervention.

This dynamic, real-world optimization not only ensures measurement accuracy and reliability but also greatly reduces manual maintenance and inspection frequency, significantly lowering long-term operational costs. Continuous data recording and analysis provide plant managers with decision-making support, such as inventory forecasting, transport scheduling optimization, and safety warning strategy development, achieving overall value enhancement from measurement to management.

In short, JWrada® radar level meters’ software capabilities are more than just a tool—they are a complete solution for intelligent operation and on-site optimization, helping companies achieve efficient, reliable, and predictable level management in complex wet gypsum stockpiles.

Installation Recommendations

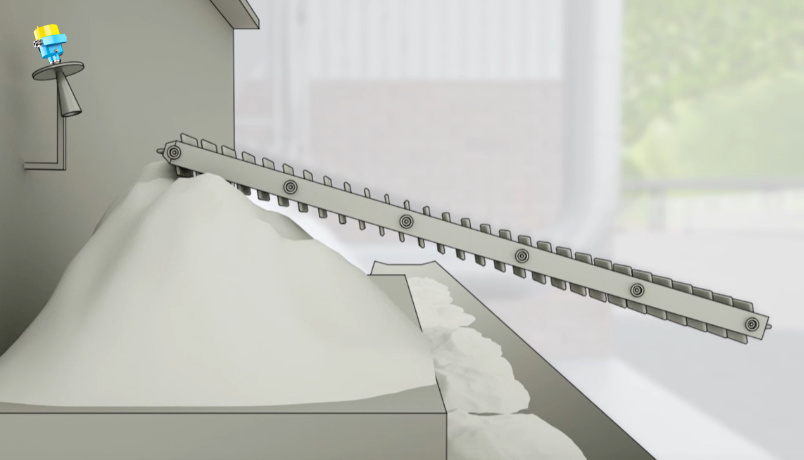

In wet gypsum stockpiles, radar level meters are typically installed:

- On top of the stockpile structure

- Above conveyor discharge areas

- Inside large-span storage buildings

At critical points, level switches can also be used in combination to build a redundant high-level protection system, achieving dual guarantees of continuous monitoring and safety protection.

Conclusion

For materials like wet gypsum with adhesion risks, the choice of measurement technology directly affects subsequent maintenance intensity and operational stability.

In more and more projects, non-contact radar is gradually replacing traditional contact solutions, becoming a key option that balances reliability and long-term operational cost.

As power plants increasingly value continuous data and predictable equipment performance, radar level measurement is no longer just a technical upgrade—it represents an advancement in material management practices.