Enhancing Silo Safety with Jiwei Flameproof Rotary Level Switches at Feed Mill

In modern animal feed production, stable material storage forms the foundation for continuous production and operational safety. Although large-scale automation systems often receive more attention, in actual plant operations, what truly determines whether production runs smoothly are those seemingly inconspicuous yet highly reliable field instruments.

Among various point-level detection technologies, rotary level switches (Rotary Level Switches) have long been a key choice for high-level detection in powder silos due to their mechanically stable structure, strong process adaptability, and long-term operational reliability.

This article introduces Gold Coin Feed Company, located in Hai Duong Province, Vietnam — the second-largest feed mill in northern Vietnam, invested and built by the U.S.-based Gold Coin Group, with an annual production capacity of approximately 300,000 tons. The article focuses on how the company, by deploying Jiwei Automation’s flameproof rotary level switches, significantly enhanced silo safety and production stability under high-dust and potentially explosive conditions.

Project Background: Preventing Overflow in High-Dust Conditions

Gold Coin Group’s feed mill in Vietnam produces a wide range of livestock and aquaculture feed products, including poultry, pigs, cattle, and aquatic feeds, covering both premixes and formulated raw materials. Such factories typically handle large quantities of powdered raw materials, such as cornmeal, soybean meal, mineral additives, and nutrient premixes, which must be stored in high-level silos to ensure the continuous operation and efficiency of subsequent batching systems.

During production, powdered raw materials — including cornmeal, soybean meal, mineral additives, and nutrient premixes — are conveyed at high speed into high-level silos via pneumatic systems, providing a continuous and stable supply of raw materials for batching operations. However, the combination of high-dust conditions and dual-feed operations significantly increases the risk of overflow. If level control is not properly managed, a series of serious issues may arise, including:

- Unplanned shutdowns and production interruptions, affecting capacity and delivery

- Dust leakage, increasing explosion and safety risks

- Increased silo pressure, posing structural hazards

- Blocked dust removal systems, reducing equipment efficiency

This context underscores the necessity of reliable high-level point protection and precise monitoring.

Engineering Challenges and Technical Requirements

To ensure reliable high-level control, the plant specified several critical requirements:

- Reliable point-level protection: The rotary level switch must actuate immediately when material reaches the set height, unaffected by dust disturbances.

- Flameproof capability: Equipment must have authoritative explosion-proof certification for combustible dust and localized gas hazards.

- High mechanical strength: Devices must withstand vibration, abrasive materials, and high-speed filling impact.

- Reduced maintenance: Minimizing personnel entry into silos improves safety.

- Scalable multi-silo deployment: Installation and commissioning should be simple and efficient, supporting large-scale production.

Point-Level Protection: Core Function of the Rotary Level Switch

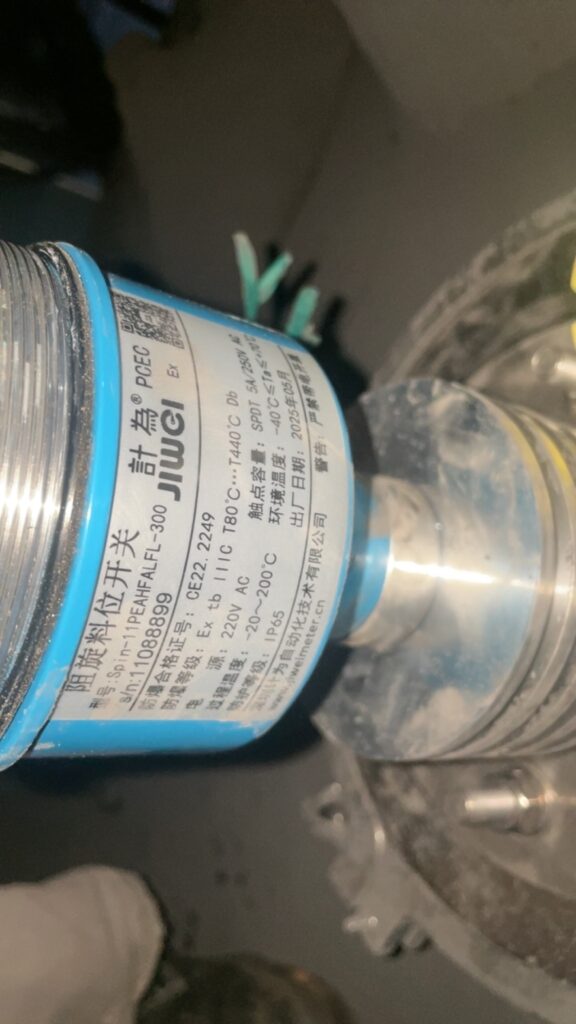

Jiwei Automation’s flameproof rotary level switches feature high-grade explosion-proof designs:

- Flameproof enclosure (Gas): Ex db IIC T6~T1 Gb

- Flameproof enclosure (Dust): Ex tb IIIC T80℃~T440℃ Db

- Combined Gas/Dust Explosion-proof: Ex db IIC T6~T1 Gb + Ex tb IIIC T80℃~T440℃ Db

The working principle of the rotary level switch is mature and reliable: a motor drives the paddle to rotate slowly, and when the material covers the paddle, the rotation is impeded, producing a torque change that triggers the switch signal, sending a high-level alert to the control system. This design offers several clear advantages:

- Unaffected by dust, providing stable actuation

- Adaptable to materials of varying densities and particle sizes

- Industrial-grade durable structure, ensuring long-term reliable operation

- Provides early warning even in dual-feed, high silos

With point-level protection, the plant can prevent overflow incidents, forming the first layer of safety defense.

Enhancing Safety and Controllability with Point-Level Protection

By deploying rotary level switches, the plant can reliably monitor high material levels, instantly detecting when silos are reaching critical heights and triggering alerts or control signals. This not only effectively prevents overflow accidents but also reduces the risks of dust leakage and silo overpressure.

The point-level protection provided by the rotary switch is a critical safeguard in high-dust and dynamic filling environments:

- The switch actuates immediately when material reaches a dangerous height, forming the first safety barrier

- Multi-point monitoring across multiple silos ensures overall plant safety

- Reduces manual inspection and intervention, improving operational efficiency and safety

This point-level protection solution provides the plant with a safe, controllable, and predictable production management capability, ensuring reliable safeguards during high-capacity operation.

Installation and Commissioning

The plant’s silos are approximately 15 meters high, with complex internal structural supports. The dual-feed high-speed filling design further increases installation and operational challenges. To ensure that rotary level switches perform reliably in such tall and structurally complex silos, the engineering team implemented a series of optimizations:

- Precisely calculated and simulated switch positions to ensure early warning before material reaches critical levels

- Reinforced paddle and shaft seal design to withstand high dust concentrations and potential material abrasion

- Optimized commissioning procedures for rapid deployment and standardized installation of multiple devices, significantly shortening project timelines and improving construction efficiency

- Provided clear status indicators and on-site visual information to allow operators to quickly assess device operation and take necessary action

After commissioning, the devices showed remarkable results: high-level alerts were stable and reliable, dust conditions no longer caused false triggers or signal failures, and operators’ confidence improved during high-speed dual-feed operations. Routine inspection and maintenance frequency decreased, reducing personnel workload and potential safety risks. The overall predictability of silo management increased significantly, providing a solid guarantee for continuous and safe production. These measures not only ensured device reliability but also established a robust first line of defense for high-capacity feed production.

System-Level Benefits and Industry Applicability

By deploying rotary level switches, the plant achieved significant system-level benefits:

- Smoother coordination between raw material receipt and batching, ensuring continuous operation without supply fluctuations

- Improved execution efficiency of production schedules, enabling operators to respond promptly to level alerts

- Reduced occurrence of unplanned downtime, preventing production interruptions due to overflow or abnormal material levels

- Lowered operational workload, minimizing the need for frequent manual silo inspections, thereby enhancing overall safety

Although this case originates from the animal feed manufacturing sector, the point-level protection provided by rotary level switches is equally applicable in other powder industries, such as grain storage and handling, cement manufacturing, chemical powder processing, biomass energy production, food ingredient processing, and mineral processing. In any high-dust, dynamic filling, or potentially explosive environment, rotary level switches provide reliable high-level protection, ensuring production safety and equipment stability.

Conclusion

The stability of industrial operations does not rely on a single “breakthrough technology” but is built on equipment and systems that consistently perform reliably and can be validated over the long term. It is these seemingly inconspicuous but highly dependable field instruments that ensure continuous and safe production processes.

By deploying Jiwei Automation’s flameproof rotary level switches, Gold Coin Feed Factory has successfully established a safe, predictable, and controllable material storage system. This system not only prevents overflow and dust leakage but also optimizes raw material management and production processes, ensuring continuous operation in a high-capacity plant while enhancing operator safety and production controllability.

In powder, high-dust, and potentially explosive environments, reliability is not merely a technical parameter; it is a capability validated through long-term operation and repeatedly trusted. This is the core of achieving safety, efficiency, and controllability in modern industrial production.