SIL Vibrating Fork Switches for Reliable Gas–Liquid Level Control

1. Project Background

A coastal energy and chemical group in Barcelona, Spain required precise level measurement in its gas treatment and wastewater gasification systems. The process involves gas–liquid separation, feed gas transfer, solvent recovery, and gas storage—where accurate level monitoring directly affects equipment safety, process stability, and production continuity.

Traditional mechanical float switches and magnetic level indicators suffered from low accuracy, fast wear, and scaling. In particular, when handling MeOH/H₂O mixtures containing CO₂, CH₄, N₂ and trace H₂S, SO₂, mechanical switches often caused false alarms or delayed responses, increasing maintenance costs and operational risks.

To ensure system safety and production continuity, the energy group procured Jiwei’s Ring-11 vibrating fork level switches (SIL 2/3 certified) through European Engineering Solutions GmbH, deploying them in critical tanks and gas–liquid separation pipelines for reliable level monitoring and safety protection.

2. Customer Requirements Analysis

Based on the process conditions, the customer specified the following key requirements:

- High reliability & fast response: switching delay ≤ 0.5 s; level deviation ≤ ±2 mm

- High-temperature and high-pressure capability: stable operation at –28°C to 150°C, 2–21 bar

- Corrosion resistance: suitable for MeOH/H₂O, CO₂, CH₄, N₂ with trace H₂S, SO₂

- Safety compliance: SIL 2/3; SIS compatibility; Ex ib IIC T3 Ga/Gb

- Low maintenance, long service life: non-mechanical design reduces scaling and maintenance frequency

- International certifications: 3C, EAC, etc., to support export and multi-country operation

3. Equipment Selection and Technical Solution

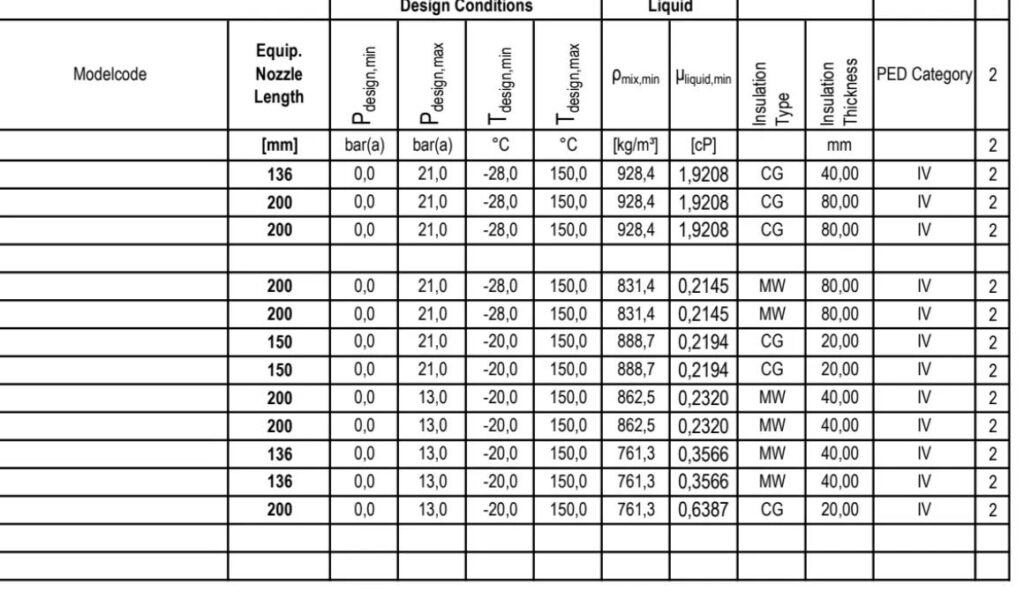

Based on process conditions, the purchaser selected multiple Ring-11 vibrating fork level switches covering various tanks and pipeline application points. The required parameters are as follows:

| Tag | Application | Medium | Pmax (bar) | Tmax (°C) | Connection | SIL | Ex Rating |

|---|---|---|---|---|---|---|---|

| LS-1481 | Overflow protection V-106 | MeOH / H₂O | 21 | 150 | DN25, PN25, EN1092-1 | SIL 1 | 1/2G Ex ib IIC T3 Ga/Gb |

| LS-2483 | Dry-run protection T-101 | CO₂, CH₄, N₂ | 15 | 90 | DN25, PN25 | SIL 2 | 1/2G Ex ib IIC T3 Ga/Gb |

| LS-2484 | Gas–liquid separation level control | MeOH/H₂O + CO₂ | 20 | 120 | DN25, PN25 | SIL 1 | 1/2G Ex ib IIC T3 Ga/Gb |

| LS-4487 | Solvent tank level control V-208 | MeOH / H₂O | 20 | 145 | DN25, PN25 | SIL 2 | 1/2G Ex ib IIC T3 Ga/Gb |

| LS-4489 | Solvent recovery monitoring | MeOH / H₂O + N₂ | 20 | 130 | DN25, PN25 | SIL 2 | 1/2G Ex ib IIC T3 Ga/Gb |

| LS-4491 | Gas storage level protection | CO₂, H₂ | 20 | 145 | DN25, PN25 | SIL 2 | 1/2G Ex ib IIC T3 Ga/Gb |

Notes:

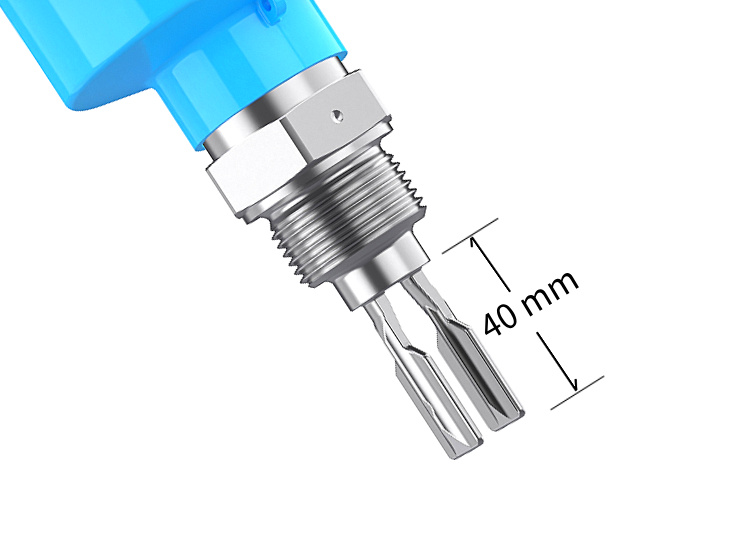

- Probes are made of 316Ti stainless steel with anti-corrosion coating for harsh gas–liquid environments.

- Ring-11 is a non-mechanical vibrating fork design, offering fast switching (≤0.5 s).

- Fully compatible with SIS, meeting SIL 2 safety integrity and explosion protection.

- Supports EN1092-1 flanges and custom connections for easy installation.

4. Implementation and Application Performance

Installation & Commissioning

Jiwei engineers installed the instruments directly without pipeline modifications. Integration with the customer’s SIS ensured reliable alarm triggering.

On-site Testing

In MeOH/H₂O mixtures and CO₂/CH₄/N₂ gas–liquid conditions, Ring-11 demonstrated high sensitivity and fast switching. Dry-run and overflow protection actions completed within 0.3–0.5 seconds, significantly improving system safety.

Long-term Operation

After over a year of continuous operation, no false triggering or maintenance failures occurred. The Ring-11 units successfully replaced mechanical float and magnetic switches, reducing maintenance workload significantly and improving operational stability.

5. Advantages of Jiwei Ring-11 Vibrating Fork Level Switches

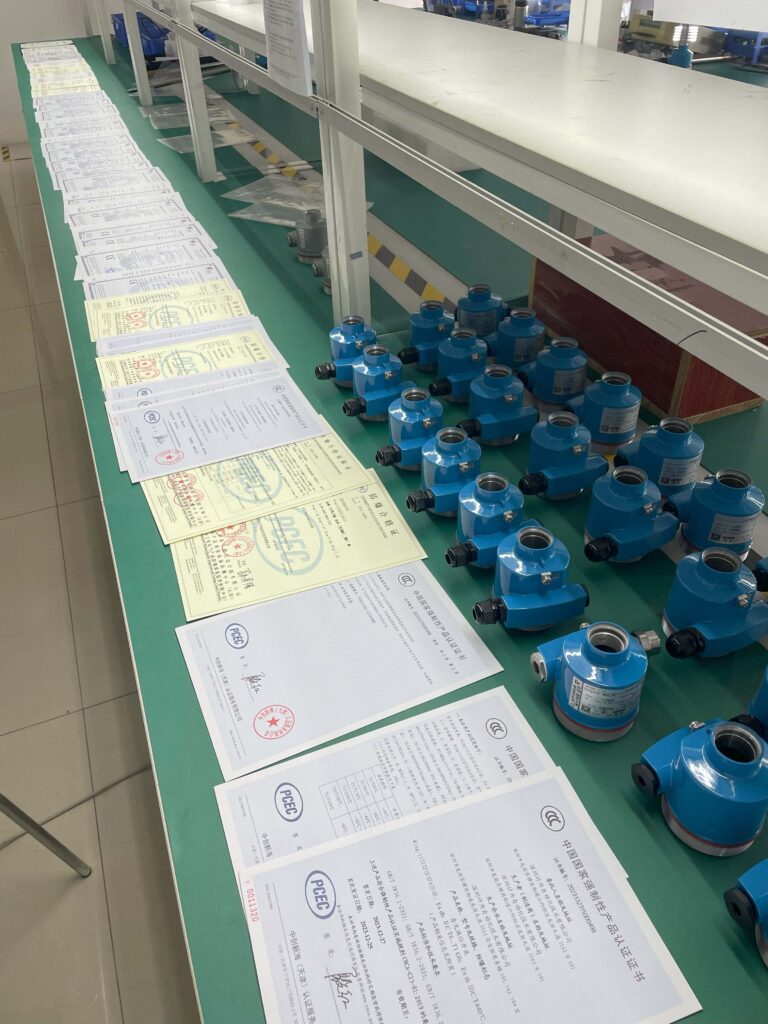

Full in-house R&D and manufacturing

Shenzhen Jiwei Automation is among the few Chinese manufacturers with complete in-house capabilities—from R&D, design, production to sales. This ensures high reliability, stability, and fast customization for complex industrial conditions.

Multiple patented technologies

Jiwei holds numerous national invention patents and software copyrights covering radar sensing, signal algorithms, and level measurement systems. These technologies enhance reliability, anti-interference capability, and long-term stability.

Extensive international project experience

Jiwei instruments are used by Sinopec, CATL, Tesla, BYD, and many global customers across chemical, energy, new energy vehicle, and food industries.

Excellent performance in complex gas–liquid systems

Featuring 316Ti stainless steel, corrosion-resistant coatings, and high-temperature/high-pressure design, the sensors maintain reliability even in harsh MeOH/H₂O and multi-gas environments.

Safety & certifications

SIL-certified, with explosion-proof options:

- Ex d IIC T6–T1 Gb

- Ex ia IIC T6–T1 Ga

- Ex db IIC T6…T1 Gb + Ex tb IIIC T440°C…T80°C Db

Low maintenance, long service life

Non-contact design eliminates wear, scaling, and frequent maintenance.

International certifications

3C, EAC and more—supporting global engineering projects.

6. Customer Feedback and Project Results

Site engineers reported:

“Since installing Jiwei’s Ring-11 vibrating fork switches, our level alarms respond faster and more reliably. Compared with previous mechanical switches, our maintenance workload has dropped by 65–70%, and unexpected downtime has been significantly reduced.”

The European engineering procurement partner commented:

“Ring-11 shows impressive stability and corrosion resistance in gas–liquid applications. Its performance provides strong reference value for future projects and greatly improves user satisfaction.”

Overall, the Ring-11 vibrating fork level switch has proven its safety, corrosion resistance, and long-term reliability in complex gas–liquid environments, becoming a trusted upgrade choice for level measurement in international energy and chemical industries.