Jiwei Modular Circuit Protection Design for Reliable Vibrating Level Switches

1. Industrial Site Background: Vulnerability of Level Switch Circuits

In industrial automation systems, reliable vibrating level switches are fundamental and critical instruments for on-site control, widely used in chemical, metallurgical, power, environmental protection, building materials, food, and pharmaceutical industries. They monitor the material status in silos, hoppers, reactors, or storage tanks and output switch signals to the control system.

Level switches typically operate under harsh conditions:

- High humidity, high dust, highly corrosive gases

- Prolonged outdoor exposure to sunlight and rain, with significant day-night temperature variations

- Frequent mechanical vibrations and impacts

- Presence of flammable and explosive hazards in some areas

Under these conditions, the stability and reliability of electronic circuits directly determine the long-term performance of the instrument. Prolonged exposure to high humidity, high dust, chemical corrosion, and strong vibrations accelerates the aging of electronic components, leading to false operations or failures of level switches. For industrial production, this implies potential safety risks, increased downtime costs, and production losses.

2. Hidden Risks in Traditional Vibrating Level Switch Circuits

To reduce costs, some domestic vibrating level switches often use conventional designs with bare PCBs installed inside metal housings:

- Circuit boards are directly exposed within the housing

- Lack of independent encapsulation and protective structures

- Rely solely on the housing seal for basic protection

While this design works in laboratory conditions, problems arise in long-term industrial environments:

- Moisture ingress causes PCB surface condensation

- Corrosive gases or salt spray accelerate component oxidation

- High humidity reduces insulation performance, increasing the risk of short circuits

- Vibration causes solder joint fatigue and intermittent faults

These issues can lead to false alarms, signal drift, increased maintenance difficulty, and downtime risk. In chemical or metallurgical industries, bare-board designs in high-humidity and corrosive environments may even cause component short circuits, potentially leading to severe safety incidents. From the perspective of safety and long-term reliability, traditional bare-board circuits have obvious limitations.

3. Importance of Circuit Protection

In modern vibrating level switch design, the level of circuit protection often determines the lower bound of instrument reliability. Even if the mechanical measurement principle is highly reliable, the instrument can fail if the electronic circuit is affected by the environment. Therefore, systematic circuit protection is an indispensable design element in high-end level switches.

Circuit protection is not only about preventing short circuits or component corrosion, but it also directly affects:

- Signal output stability

- Long-term operational reliability of the instrument

- Industrial safety risk control

- Equipment maintenance costs

By scientifically designing circuit protection, the service life of level switches under complex conditions can be significantly extended, while reducing on-site maintenance frequency.

4. Jiwei Automation’s Modular Circuit Protection Design

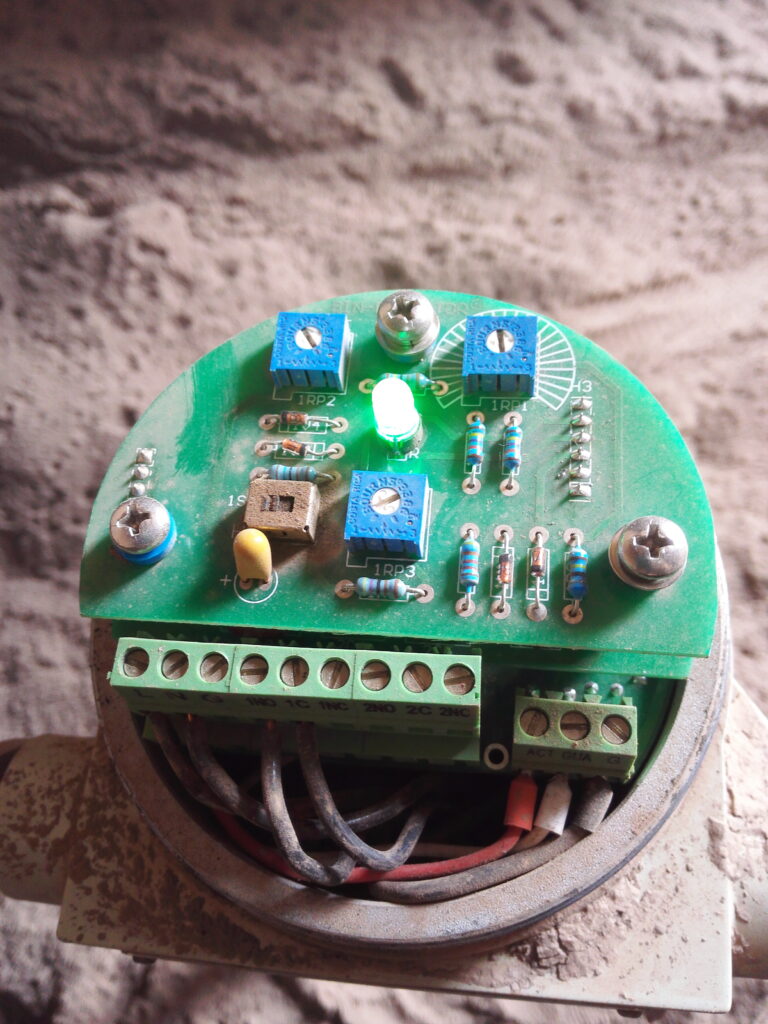

Shenzhen Jiwei Automation Technology Co., Ltd. adopts a modular design combined with potting technology in R&D, with the following core features:

- Independent Circuit Encapsulation

The entire working PCB is placed in a dedicated plastic box, achieving physical isolation from the external environment. Modular design decouples the circuit from the housing, reducing the direct impact of vibration transmission and environmental intrusion on the circuit. - Integrated Potting

During encapsulation, high-performance potting compound is injected to form a dense protective layer over the PCB and components, enhancing mechanical fixation and insulation performance. The potting compound also has a certain degree of flexibility, which absorbs mechanical shocks and vibrations, improving vibration resistance.

5. Technical Advantages of Modular Circuit Protection

- Waterproof and Moisture-Proof

The potted circuit module effectively blocks humidity, preventing condensation on the PCB from forming conductive paths. Even in continuously humid or condensing environments, the circuit remains stable. - Corrosion Resistance

Potting and plastic modules isolate chemical gases and salt spray, preventing oxidation of component leads and electrochemical corrosion, especially suitable for chemical, environmental, and coastal high-salt environments. - Insulation and Flame Retardant

Modular encapsulation uses flame-retardant insulating materials, reducing the risk of short circuits and leakage, while complying with intrinsic safety (Ex ia) requirements, providing technical assurance for safe operation. - Vibration and Shock Resistance

The potting compound absorbs mechanical energy, protecting solder joints and components, enhancing industrial on-site reliability. Even in frequently vibrating conveyor equipment, mixing tanks, or heavy-duty hoppers, level switches can operate stably for extended periods. - Maintainability

Modular design allows quick replacement of circuit modules without disassembling the entire instrument or performing on-site soldering, significantly reducing downtime and maintenance costs. It also enables rapid electronic module upgrades, keeping the instrument technologically current.

6. On-Site Application Case

In acid tank level monitoring in chemical plants, some customers previously used a domestic S-brand bare-board vibrating level switch. Its PCB was directly exposed within the metal housing and operated in environments with high acid mist concentration and temperature fluctuations. Over time, acid mist and moisture accumulated on the bare PCB surface, accelerating component corrosion and solder joint fatigue, causing delayed actions, frequent false alarms, and even short circuits or failures. Users had to frequently stop production to replace instruments, increasing maintenance costs and affecting production stability.

In contrast, Jiwei Automation adopts a modular circuit + potting design, placing the entire working PCB in a plastic module box and injecting high-performance potting compound to form a complete protective layer. In the same acid mist environment, Jiwei modular level switches maintain long-term stable alarms and signal output, effectively avoiding downtime, reducing maintenance costs, and ensuring safe and reliable production processes.

7. Quality Control and Standardized Design

Jiwei Automation ensures high consistency in size, craftsmanship, and performance of each level switch through modular circuit protection and strict factory testing:

- Jiwei Automation relies on modular circuit protection and rigorous factory inspection to guarantee high consistency in size, craftsmanship, and performance for each level switch

- Potting processes are tested under high and low temperatures, humidity, vibration, and salt spray conditions

- Components and finished products undergo strict sampling to ensure standardization

- Mass production maintains stability and reliability, reducing risks associated with customization

Standardized design not only improves product consistency but also ensures that customers achieve the same reliable performance across different projects and operating conditions.

8. Cost and Maintenance Advantages

Modular circuit protection significantly reduces on-site maintenance frequency and complexity while effectively lowering production line downtime, indirectly saving substantial production costs. Compared with traditional bare-board or non-modular designs, maintenance personnel do not need to disassemble the entire instrument or perform complex soldering; they only need to quickly replace the complete circuit module to restore normal operation. The process is simple, safe, and reliable, allowing general on-site maintenance staff to perform it easily, avoiding potential risks caused by human errors. Additionally, modular design facilitates future electronic module upgrades or modifications, enabling enterprises to maintain long-term stable operation of existing equipment while quickly adapting to new processes or operating conditions, thereby improving overall production efficiency and on-site management, and optimizing maintenance cost, time, and productivity.

9. Industry Recognition and Safety Standards

Jiwei Automation’s modular circuit protection reliable vibrating level switches comply with intrinsic safety (Ex ia) requirements and have been validated through PCEC, 3C, SIL, EAC, and international customer cases. They can operate stably over the long term in strict industrial environments. This series of instruments is widely applicable to chemical, metallurgical, energy, pharmaceutical, and food industries with high risk, high corrosion, and high wear conditions, meeting the strict safety, explosion-proof, and reliability requirements of global markets.

10. Conclusion

Circuit protection is the core of long-term stable operation for reliable vibrating level switches. Through modular + potting design, Jiwei Automation integrates waterproofing, corrosion resistance, insulation, flame retardancy, and vibration resistance systematically, ensuring instruments remain reliable and durable in complex industrial environments. This design not only enhances product performance but also reduces maintenance costs, saving enterprises time and resources.