Do Thermal Insulation and Jackets Affect Magnetic Level Gauges?

An Analysis of Asbestos Tape, Vacuum Jackets, and Outer Pipe Materials

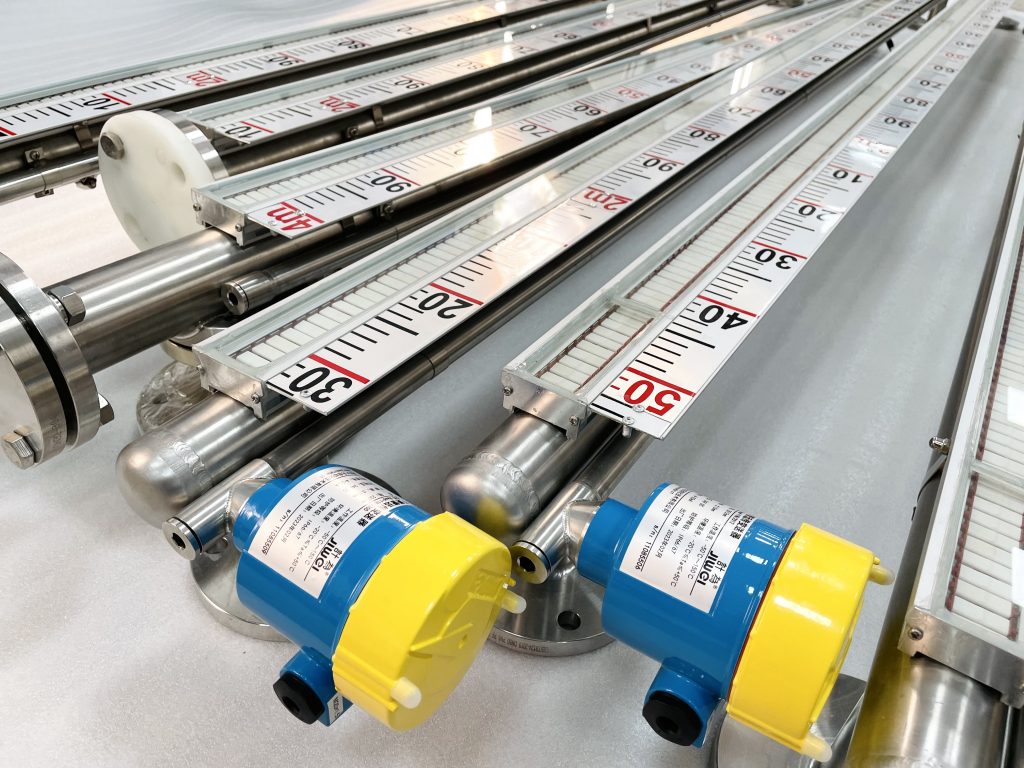

In industrial sites such as chemical processing, energy, metallurgy, and pharmaceuticals, magnetic level gauges are rarely installed in a “bare” configuration.

Under operating conditions involving high temperature, low temperature, strong radiation, or strict personnel protection requirements, various thermal insulation or protective measures are commonly applied to the measuring tube. These may include asbestos tape wrapping, insulation blankets, metal protective covers, or even vacuum jacket structures.

This naturally raises a typical engineering question:

Do these insulation layers or jacket structures weaken the magnetic field of a magnetic level gauge and cause display malfunctions?

This issue is frequently discussed in the field. However, in many cases, conclusions are based largely on experience or even misconceptions rather than a clear understanding of the underlying mechanism. This article provides a systematic analysis of the topic from the perspectives of the operating principle of magnetic level gauges, the magnetic properties of different materials, the real impact of insulation structures, and common engineering misjudgments.

1. Magnetic Field Operating Principle of Magnetic Level Gauges

The core of a magnetic level gauge lies not in the indicator itself, but in the float system.

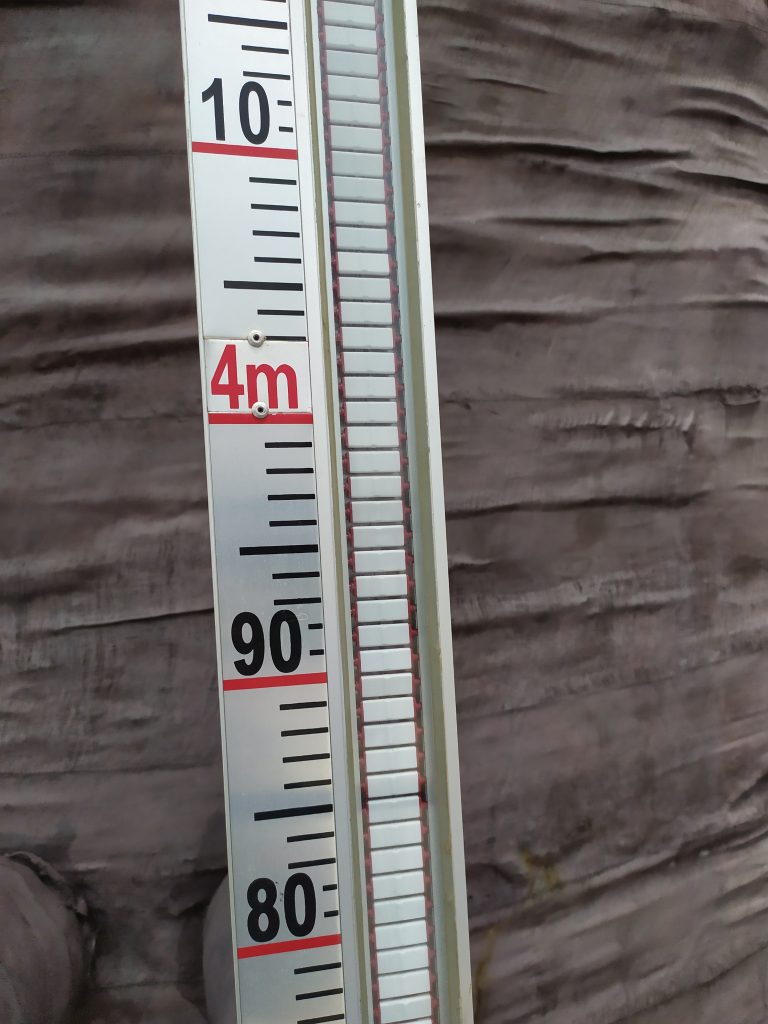

A high-performance permanent magnet is embedded inside the float. As the float moves up and down with the liquid level, the magnetic field generated by the magnet passes through the measuring tube wall and drives the magnetic flaps inside the external indicator to rotate, forming a clear visual level indication.

From the perspective of magnetic field transmission, the magnetic flux must complete three steps:

- Emanate from the permanent magnet inside the float

- Penetrate the measuring tube wall

- Act on the magnetic elements of the indicator flaps

This process relies on the penetration capability of a static magnetic field, rather than electromagnetic induction or signal transmission. Therefore, any discussion about whether the magnetic field is affected must return to one fundamental question:

Is the magnetic field absorbed, redirected, or weakened by the materials it passes through?

2. Which Materials Truly Affect Magnetic Fields?

In engineering practice, not all materials have an impact on magnetic fields.

2.1 Materials That Require Particular Attention

The materials that have the most significant influence on the magnetic field of a magnetic level gauge are ferromagnetic materials, mainly including:

- Carbon steel

- Low-alloy steel

- Martensitic stainless steel (400 series)

- High-permeability specialty alloys

These materials share a common characteristic: their magnetic permeability is much higher than that of air. As a result, they strongly attract magnetic flux and redistribute magnetic field lines. If continuous ferromagnetic materials are present along the magnetic field transmission path, a so-called “magnetic short circuit” may form, reducing the effective magnetic field strength acting on the indicator.

2.2 Materials That Have Negligible Influence on Magnetic Fields

In contrast, many commonly used insulation and protective materials do not possess magnetic shielding properties, such as:

- Asbestos tape

- Glass fiber and ceramic fiber

- Various insulation blankets

- Air or vacuum layers

- Austenitic stainless steels (304, 316, 316L)

The magnetic permeability of these materials is close to that of air. From a magnetic field perspective, they are essentially equivalent to free space and do not cause any meaningful interference with magnetic flux transmission.

3. Impact of Asbestos Tape and Conventional Insulation Layers

In industrial applications, asbestos tape is mainly used for thermal insulation, fire protection, and burn prevention. It is essentially an inorganic mineral fiber material. From a material property standpoint, asbestos is non-magnetic and does not shield or attenuate magnetic fields.

In magnetic level gauge applications, asbestos tape is typically wrapped or applied around the measuring tube. From a magnetic field perspective, this structure introduces only one change:

A slight increase in the magnetic field transmission distance.

It should be emphasized that magnetic level gauges are designed with sufficient operating distance margins. The magnetic field strength of the float magnet is far greater than the minimum magnetic flux density required to actuate the indicator flaps. Therefore, under normal engineering conditions, conventional insulation thicknesses and properly designed insulation structures do not affect the display reliability of magnetic level gauges. Only in cases of excessively thick insulation combined with other unfavorable structural factors does further evaluation become necessary.

4. Influence of Vacuum Jacket Structures on Magnetic Fields

Vacuum jackets are commonly used in high-temperature or low-temperature applications, where insulation performance is achieved by reducing heat conduction and convection. From a magnetic field standpoint, a vacuum layer is essentially no different from air.

Magnetic fields can propagate freely through a vacuum without being absorbed or reflected. Therefore:

The “vacuum” itself in a vacuum jacket has no impact on the magnetic field of a magnetic level gauge.

5. Influence of Pipe Material on Magnetic Field Transmission

In practical engineering applications, problems rarely arise from the vacuum layer itself, but rather from the material selection of the outer jacket pipe.

In jacketed or externally protected magnetic level gauges, the choice of outer pipe material is often more critical than the insulation method. Magnetic level gauges rely on the magnetic field generated by the permanent magnet inside the float. The magnetic field must pass through the inner pipe and act on the external indicator flaps. Any structure located along this transmission path participates, to some extent, in the magnetic circuit.

When the outer pipe is made of 304 or 316 austenitic stainless steel, its magnetic permeability is close to that of air, and it barely participates in the magnetic circuit. Magnetic flux can pass through the pipe wall and jacket structure relatively freely. In this case, magnetic field attenuation is mainly due to increased distance rather than material absorption. Within reasonable structural dimensions and design margins, the influence of 304/316 stainless steel outer pipes on magnetic level gauge indication can be considered minimal or negligible. This is also the most common and reliable engineering choice for jacketed magnetic level gauges.

By contrast, when the outer pipe is made of carbon steel or magnetic alloy steel, the situation changes significantly. These materials have high magnetic permeability and actively attract magnetic flux, forming localized closed magnetic paths within the outer pipe. As a result, the magnetic flux that should act on the indicator flaps is partially diverted or weakened. Typical field symptoms include delayed flap rotation, discontinuous indication at certain heights, or unstable indication during rapid level changes. These issues do not indicate a failure of the magnetic level gauge itself, but rather that the outer pipe material has unintentionally acted as a magnetic shield.

Therefore, in magnetic level gauge applications requiring jackets or external protective pipes, selecting 304 or 316 stainless steel outer pipes is a key prerequisite for ensuring reliable magnetic field transmission and stable indication. If carbon steel outer pipes must be used due to structural or cost constraints, the magnetic field operating distance, indicator structure, and magnet specification should be specifically evaluated during the design stage, rather than simply applying standard configurations.

This is also why, in some jacketed magnetic level gauge applications, phenomena such as partial non-flipping or delayed indication occur—the root cause is not insulation, but improper material selection.

6. Real Causes Often Misjudged as “Insulation Problems”

In many field cases, abnormal magnetic level gauge indication is quickly attributed to the presence of insulation. However, actual troubleshooting shows that the real causes are more commonly related to:

- Incorrect installation of float magnetic polarity

- Insufficient magnet specification or magnet demagnetization

- Excessive measuring tube wall thickness

- Abnormal spacing between the indicator and the measuring tube

- Installation of carbon steel protective covers

- Degradation of magnetic properties of indicator flaps under high temperature

Compared with these factors, asbestos tape and vacuum jackets are often simply “wrongly blamed.”

7. Engineering Conclusions and Design Recommendations

Based on magnetic field principles, material properties, and engineering experience, the following conclusions can be clearly drawn:

- Asbestos tape, insulation blankets, and ceramic fibers

do not shield the magnetic field of magnetic level gauges - The vacuum layer in a vacuum jacket

does not affect magnetic field transmission - What truly requires caution

is the interference of ferromagnetic materials with the magnetic circuit

During engineering design and product selection, special attention should be paid to the material properties of the measuring tube and jacket outer pipe, ensuring that continuous ferromagnetic structures are avoided along the magnetic field transmission path.

Conclusion

Magnetic level gauges are not afraid of insulation, nor of jacket structures. Whether asbestos tape, insulation blankets, or vacuum jackets are used, they do not fundamentally interfere with magnetic field transmission. What magnetic level gauges truly “fear” is the unintended introduction of ferromagnetic materials into the magnetic field path. Once such materials alter the magnetic circuit distribution, effective magnetic flux is reduced, ultimately affecting indication stability and long-term reliability.