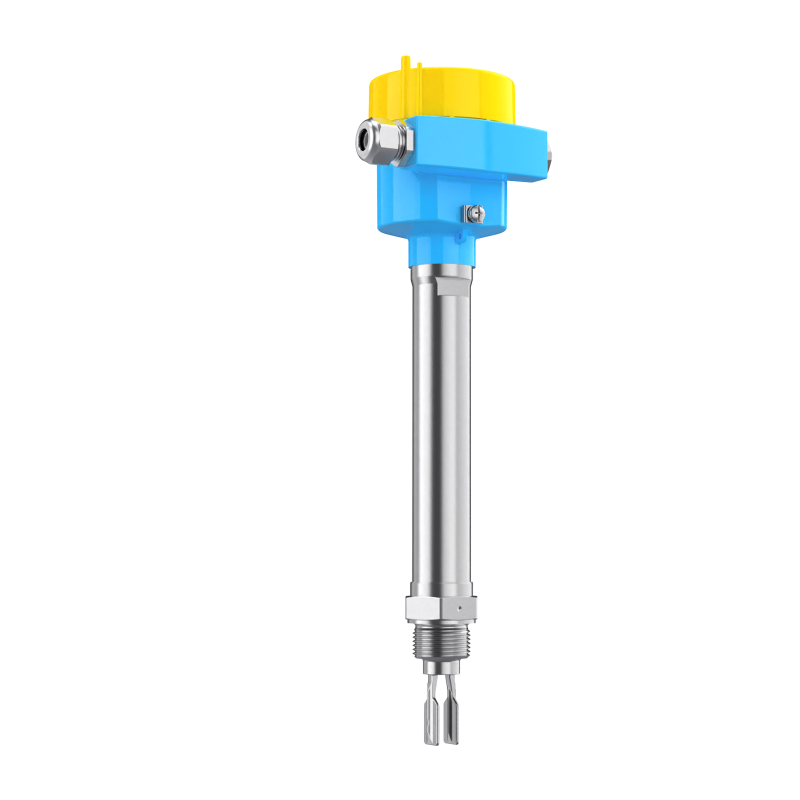

Ring-11 Liquid Level Switch with Gas-tight Leadthrough

The special setting of high-pressure protective gas-tight leadthrough makes Ring-11 High-pressure Liquid Level Switch effectively prevent accidental leakage of high-pressure strong corrosive liquid.

The Jiwei Ring-11 with Gas-tight Leadthrough is a versatile level switch designed for use in all liquids. As a point level sensor with a tuning fork for point level detection, it is specifically engineered for industrial applications across all areas of process technology.

It operates reliably even under challenging conditions such as turbulence, air bubbles, foam generation, build-up, strong external vibration, or fluctuating products.

The gas-tight lead-through version is designed for use in toxic gases, high-pressure, and high-temperature applications. The high-pressure protective gas-tight leadthrough of the Jiwei Ring-11 High-pressure Protection Liquid Level Switch features a glass-metal encapsulation connector that connects the process connection and meter head. The sealing effect is achieved through the cooperation of borosilicate glass and stainless steel, which prevents the fork body from penetrating under high temperature and high pressure over time, protecting the electronic module from exposure to high-temperature liquids. This design also prevents accidental leakage by avoiding the flushing out of the housing.

Furthermore, the high-pressure gas-tight leadthrough also shields the piezoelectric components from moisture, ensuring long-term durability.

This special configuration of the high-pressure protective gas-tight leadthrough allows the Ring-11 High-pressure Liquid Level Switch to effectively prevent the accidental leakage of high-pressure corrosive liquids.

Piezoelectric devices are used to drive vibration and detect changes. When the resonant vibration fork contacts the application medium, its vibration frequency decreases significantly. This reduction in frequency is reflected in the output signal from the piezoelectric detection device. An integrated circuit then analyzes this signal and generates a switch signal in response.

● Precise and reliable operation with a product-independent switching point for consistent performance.

● Minimal time and cost investment thanks to simple setup without the need for a medium.

● The electronic components are modularized for easier maintenance and flexibility.

● The high-temperature extension tube is available with ECTFE and PFA coatings for enhanced durability.

● Output options include relay, transistor, two-wire, and NAMUR for versatile integration into your system.

● Specialized for the process industry, the product is developed according to IEC 61508 and designed for direct use in SIL2 and SIL3 applications, ensuring safety in critical operations.

● CE and EAC certifications for compliance with European and Eurasian safety standards.

● Complies with HACCP, and 3A standards, ensuring safety, hygiene, and reliability in the food and pharmaceutical industries.

| Applicable liquid | Density | ≥0.5g/cm³ |

| Viscosity | 0.1~10000mPa.s① | |

| Flow velocity | Max. 6m/s | |

| Probe data | Surface finish | Ra<0.5μm② |

| Vibration frequency | ~1200Hz | |

| Fork length | 40mm | |

| Accuracy | Measurement error | ±1mm |

| Delay | 2mm | |

| Repeatability | 0.1mm | |

| Switching delay | When immersed | 0.5s |

| When laid bare | 1s | |

| Power supply③ | Relay | 20~253V AC/20~72V DC |

| Two-wire | 10~36V DC | |

| NAMUR | 8.2V DC | |

| Transistor | 6~48V DC | |

| Max. power consumption | 8VA(AC);1.5W(DC) | |

| Output | Relay | 5A/253V AC/24V DC |

| Two-wire | 8mA/16mA,Alarm<2.3mA | |

| NAMUR | ≤1mA or ≥2.1mA, Fault ≤1mA | |

| Transistor | NPN/PNP | |

| Installation conditions④ | Process pressure | -1~64bar |

| Process temperature | Regular temperature: -50~150℃ | |

| High temperature: -50~280℃ | ||

| Ultra-high temperature: -50~400℃⑤ | ||

| Ambient temperature | -40~70℃ | |

| Storage and transport temperature | -40~80℃ | |

| Overvoltage protection | Relay | Category III, class I |

| Two-wire | Category III, class II | |

| Certificates and approvals | SIL Qualification⑥ | SIL2 (HFT=0) / SIL3 (HFT=1) |

| Explosion-Proof | Intrinsic Safety: Ex ia IIC T1…T6 Ga | |

| Flameproof Enclosure: Ex db IIC T6…T1 Gb | ||

| Gas/Dust Explosion-proof: Ex db IIC T6…T1 Gb + Ex tb ⅢC T440℃…T80℃ Db | ||

| CE | LVD and EMC Certificates | |

| Ingress Protection | IP66/IP67 | |

| Materials | Housing | Aluminum alloy, stainless steel |

| Ground terminal | 316L | |

| Thread connection | 316L | |

| Flange connection | 316L, 316L coated Enamel, ECTFE, PFA | |

| Fork | 316L, 316L coated Enamel, ECTFE, PFA | |

| Process seal | Klingersil C-4400 |

Note:

① Assume the medium density equals to 1.

② Applicable: for Hygienic Ring-11 only.

③ The voltage of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

④ The relationship between the process temperature, medium temperature and ambient temperature of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

⑤ Designed with water cooling for ultra-high temperature applications.

⑥ Comply with international standard IEC61508 (national standard GB/T20438).

● Chemical Industry: Ideal for high-pressure and high-temperature conditions in chemical reactors and corrosive liquid storage tanks, ensuring reliable level measurement in extreme environments.

● Pharmaceutical Manufacturing: Used in mixing tanks and sterilization vessels, the Ring-11 with Gas-tight Leadthrough provides accurate level detection under high pressure and temperature.

● Food and Beverage: Perfect for high-temperature pasteurization and pressurized fermentation systems, offering durable and precise measurement in demanding food processing environments.

● Water Treatment Plants: Reliable in pressurized tanks and chemical dosing systems, ensuring precise level measurement in high-pressure water treatment applications.

● Oil and Gas: Suited for offshore rigs and high-pressure storage, the Ring-11 with Gas-tight Leadthrough operates safely in hazardous environments, providing consistent performance in extreme conditions.

● Marine Industry: Provides accurate level detection in fuel systems and cargo holds of ships, withstanding high-pressure and harsh marine conditions.

● Power Plants: Ideal for cooling systems and high-pressure steam systems, ensuring reliable liquid level monitoring in extreme temperature and pressure conditions.