Application of Jiwei PRO Radar Level Transmitters in Heavy Oil Tank Level Measurement

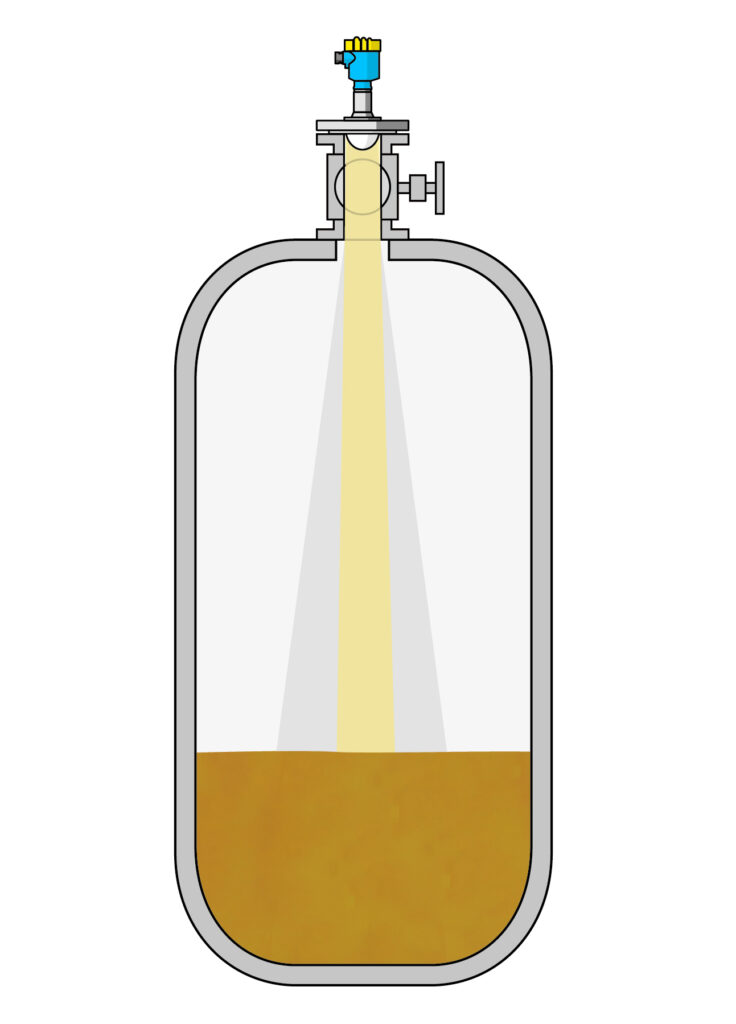

Radar level transmitters have become the preferred solution for addressing these challenges in refineries and petrochemical plants. With their non-contact measurement principle, high-frequency signal processing, and excellent adaptability to harsh environments, Jiwei PRO radar level transmitters can provide continuous, stable, and accurate level monitoring for heavy oil tanks, ensuring both operational safety and production efficiency.

With increasing process complexity and stricter environmental and safety standards, companies demand higher accuracy, reliability, and continuity in level measurement. Against this background, Jiwei Automations PRO series radar level transmitters, with their non-contact, high-frequency signal processing and excellent environmental adaptability, have become an important tool to solve the heavy oil tank level measurement problem. This article analyzes technical challenges, radar advantages, application solutions, and practical cases to demonstrate effective solutions.

Technical Challenges of Heavy Oil Tank Level Measurement

The complexity of heavy oil tank level measurement arises from multiple factors. High viscosity and low flowability result in slow liquid surface changes, making conventional float or rotary paddle instruments respond slowly and causing significant measurement delays. Low dielectric constant of heavy oil weakens radar or other signal reflection, causing measurement fluctuations. Temperature gradients and thermal stratification in tanks further complicate measurement, as vertical temperature differences and vapor layers interfere with instrument readings.

Foam, emulsions, and vapor in tanks can produce false echoes, affecting the recognition of the true liquid surface. Sulfur or tar impurities in heavy oil may accumulate or form deposits on the sensor surface, causing contact-type instruments to fail. Complex tank internals, such as mixers, heating coils, or support structures, also create multiple reflection paths, increasing signal interference. Overall, heavy oil tank level measurement involves multi-factor interference, high difficulty, and high risk, requiring reliable, stable, and robust measurement technologies.

Advantages of Jiwei PRO Radar Level Transmitters

Jiwei PRO series radar level transmitters demonstrate significant advantages in heavy oil tank applications. Their non-contact measurement principle avoids any contact with the medium, preventing the effects of high viscosity, deposition, and corrosion on measurement accuracy. Non-mechanical design reduces maintenance costs and allows long-term stable operation, suitable for heavy oil tanks.

High-frequency signals and narrow beam design are core technologies of the PRO series. The 80 GHz high-frequency radar penetrates complex internal structures and focuses on the liquid surface. Even low-dielectric heavy oil can maintain strong echo signals for precise measurement. The built-in intelligent multi-echo processing algorithm distinguishes real liquid level from obstacles, multiple reflections, vapor layers, and foam interference, significantly reducing false alarms and signal drift.

The PRO series also performs reliably under high temperature and high viscosity conditions, operating from -50°C to 150°C, resistant to steam, thermal shock, and temperature gradients. It is suitable for heated jackets and steam-covered tanks. In terms of automation integration, Jiwei radar supports 4–20 mA/HART output, compatible with PLC, DCS, and SIS systems, and can be used in SIL safety loops for comprehensive control and risk management. Built-in Bluetooth allows connection to Jiwei Smart Control® mini-program and self-developed APP, enabling remote parameter setting, real-time monitoring, and data upgrades, achieving intelligent operation and maintenance.

Solutions for Heavy Oil Tank Level Measurement

Jiwei provides comprehensive solutions for heavy oil tanks. First, continuous level monitoring via high-frequency radar achieves full-range real-time measurement, outputs data to control systems to prevent overflow or pump dry-run, and integrates temperature and pressure monitoring for precise material management.

Second, in tanks with oil-water separation, PRO series radar accurately detects interface height, providing stable data even with thick emulsions or impurities, supporting drainage, pumping, and distillation processes.

Third, intelligent algorithms automatically identify false echoes from foam and vapor, avoiding false level alarms and ensuring continuous monitoring in dynamic environments. For high-viscosity liquids, radar signals penetrate thick oil layers with strong echoes, avoiding interference from mechanical floats or rotary paddles, and enabling high-accuracy measurement of heavy oil, tar, and residue oil.

Other brands’ radar level probes may be covered or adhered by heavy oil, resulting in inaccurate measurements, highlighting the advantage of Jiwei PRO series radar.

Practical Cases

At a refinery, a heavy oil tank at 80°C with conventional float instruments often stuck and produced inaccurate readings. After installing the PRO series radar, continuous real-time level monitoring was achieved, with stable echo signals ensuring accurate pump protection, overfill prevention, and inventory management.

In a heated jacket residue oil tank with strong temperature gradients and high viscosity, the PRO series radar provided real-time level feedback, supporting automatic heating and pump control, reducing manual inspection frequency and maintenance costs by 60%.

In a desalter tank with obvious oil-water emulsification, the radar accurately identified the interface, improving desalting efficiency and enhancing downstream distillation tower stability. These cases demonstrate that Jiwei radar achieves high-precision, continuous, and stable level measurement in complex heavy oil tank environments, significantly enhancing safety and operational efficiency.

Value of Heavy Oil Tank Level Measurement

Accurate level measurement improves safety and optimizes production efficiency. Continuous and stable data prevent overflow, pump dry-run, and pipeline leakage, reducing risk. Real-time monitoring supports automation, reduces manual intervention, and increases plant utilization. Non-contact design reduces wear and adhesion, lowering downtime and maintenance costs.

High-precision measurement supports environmental compliance, such as overfill protection, leakage prevention, and VOC control. Accurate inventory data aids supply chain planning and resource allocation, enabling cost optimization and efficient operation.

Conclusion

Heavy oil tank level measurement is a challenge in refineries and petrochemical plants. Traditional instruments struggle under high viscosity, low dielectric, vapor interference, and complex tank structures. Jiwei PRO series radar level transmitters provide mature solutions with non-contact measurement, high-frequency signals, intelligent algorithms, and high-temperature/high-viscosity resistance.

Deploying PRO series radar enables continuous, stable, and drift-free measurement, precise monitoring of high-viscosity and low-dielectric heavy oil, elimination of foam, vapor, and internal structure interference, and seamless integration with automation systems, improving safety and operational efficiency. For enterprises seeking higher safety margins, lower maintenance costs, and higher measurement accuracy, Jiwei radar level transmitters have become an indispensable tool for heavy oil tank level measurement.