Sugar Boiling Condensate Tank Level Measurement — Radar Level Meter

Industry Background

In sugar production, the sugar boiling section is the core of both energy consumption and automation control. During the evaporation and concentration stages, sugar solution undergoes heating, evaporation, and crystallization inside the sugar boiling tank. This process generates a large amount of condensate steam. To prevent overpressure and energy loss, “condensate equalizing tanks” are commonly used to collect condensate and balance steam pressure and liquid levels.

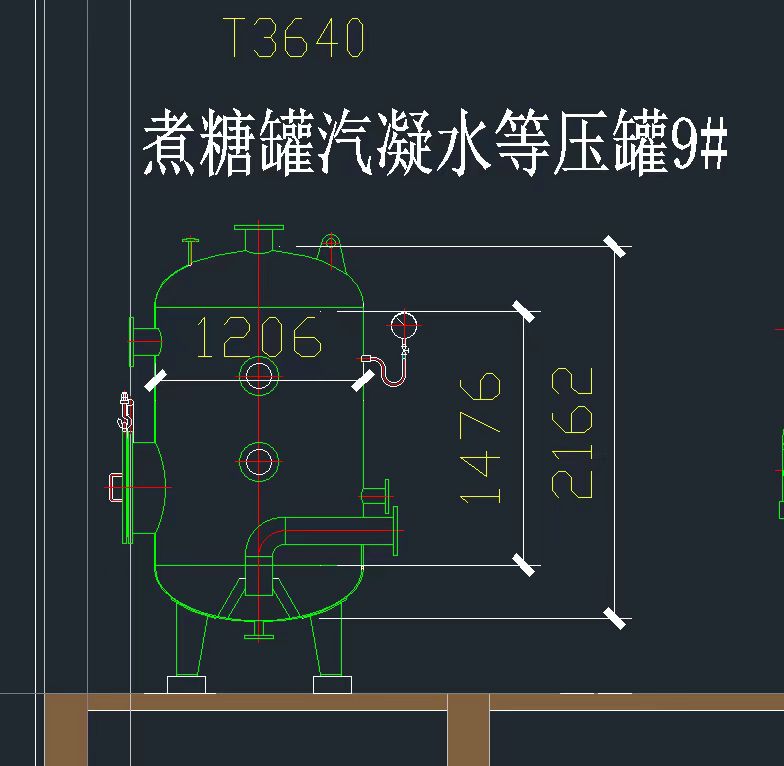

The equalizing tank (equipment No. T3640) has a diameter of approximately 1206 mm and a total height of 2162 mm. It is a sealed vessel operating under fluctuating temperature and pressure. The tank stores condensate from the sugar boiling jacket, maintaining system pressure balance and controlling the condensate pump or steam valve through level signal interlock, ensuring stable operation of the heating system.

However, the presence of steam bubbles, high temperature, rapid condensation, and frequent liquid level fluctuations make traditional float or differential pressure level meters unreliable. They often suffer from unstable readings, delayed signals, or complete failure. Therefore, achieving stable level measurement in a high-temperature, humid, steam-rich environment has become a key challenge in sugar factory process control.

Technical Challenges

High-Temperature and High-Pressure Environment

The condensate tank typically operates between 90–130°C, with pressure near saturated steam levels (0.2–0.4 MPa). This demands exceptional temperature resistance and sealing reliability from the measuring instrument.

Coexistence of Steam and Condensate

A layer of hot steam often exists above the liquid surface, easily generating false echoes that cause drift in ultrasonic or guided wave radar signals.

Condensation and Droplet Interference

Condensate may adhere to the probe surface due to wall temperature changes. Without proper signal attenuation or phase correction, measurement accuracy is affected.

Limited Space and Installation Constraints

The tank’s diameter of only 1.2 meters leaves minimal space at the top, requiring a compact, maintenance-free, top-mounted solution.

Hygienic Design Requirements

Since the condensate system is part of the sugar production process, all equipment must comply with sanitary design standards to prevent contamination.

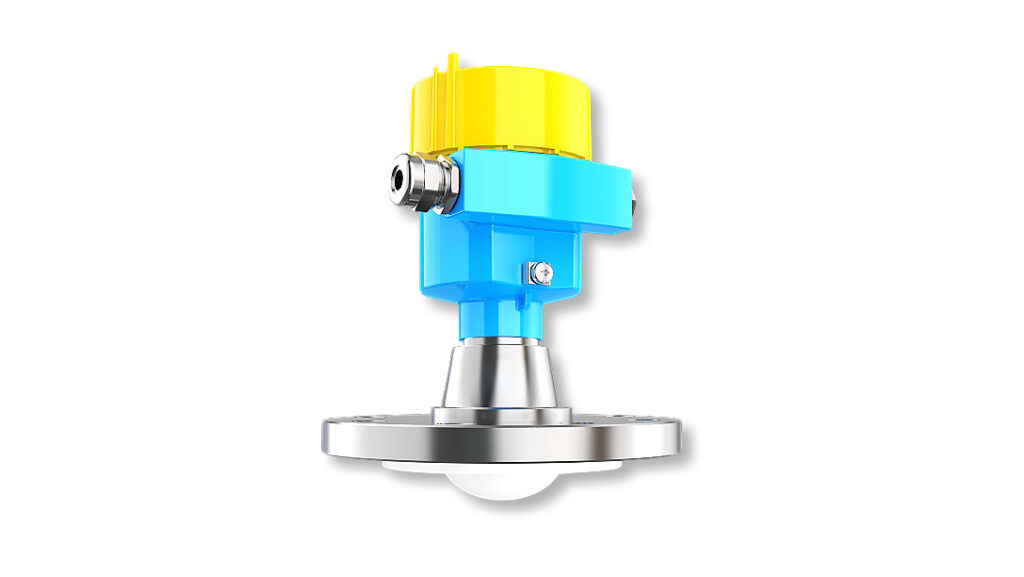

Jiwei Solution — JWrada® 80GHz Radar Level Meter

To meet the demanding conditions of the sugar boiling condensate equalizing tank, Jiwei Automations recommends the JWrada® 80GHz high-frequency radar level meter, which enables non-contact continuous level measurement.

Design and Principle

The JWrada® radar level meter operates on FMCW (Frequency Modulated Continuous Wave) technology, working in the 80 GHz frequency band with a narrow 3° beam angle. This allows focused measurement even in small vessels. The radar transmits microwaves to the liquid surface, receives reflected echoes, and calculates level height through time–frequency analysis.

With its strong signal penetration and immunity to steam, foam, and temperature variations, the high-frequency radar is particularly suitable for condensate tanks.

Key Features

- High Temperature Resistance: Operates reliably from –40°C to +220°C. The standard version suits condensate equalizing tanks, while a high-temperature version is available for extreme conditions.

- Steam and Condensate Interference Elimination: Built-in steam compensation and multi-echo recognition algorithms automatically distinguish false reflections.

- Non-Contact Measurement: The antenna does not touch the medium, avoiding cleaning or fouling.

- Compact Design: Features a Φ40mm horn antenna, suitable for DN50 top flange installation.

- High Accuracy: Maximum measuring range up to 150 m (options: 60 m, 120 m, 150 m); accuracy within ±1 mm. Actual setting: 0–2000 mm (slightly below the 2162 mm tank height, leaving safety margin).

- Flexible Communication: Supports 4–20 mA, HART, and RS485 (Modbus RTU), easily integrating with DCS or PLC systems.

Technical Analysis

1. Steam Interference Suppression

The JWrada® radar employs an “echo identification algorithm” to analyze multi-path reflections in real time, filtering out signals from condensate vapor layers and isolating the true liquid surface echo.

2. Temperature Compensation

Built-in temperature sensors perform real-time propagation speed compensation to ensure stability under high-temperature conditions.

3. Adaptive Echo Tracking

Even with rapid level changes, the dynamic echo-locking algorithm maintains continuous tracking of the actual liquid surface, with response times under 0.2 seconds.

4. Hygienic Design

The PTFE-encapsulated antenna meets CIP/SIP cleaning standards and complies with GB 28050/FDA food-contact requirements, ensuring hygienic operation in condensate systems.

Implementation and Performance

In this sugar plant project, the JWrada® radar level meter was installed vertically on the top flange of the tank, transmitting signals directly to the DCS for automatic control. The installation position was chosen at the tank center to avoid the steam inlet and return pipe, ensuring an unobstructed radar beam. The output signal (4–20 mA + HART) controls the condensate drain valve and pump, with a configured range of 0–2000 mm (below the total tank height of 2162 mm).

During commissioning, technicians used a HART communicator to monitor echo curves in real time. The results showed smooth level curves with no false fluctuations, response time <0.3 s, measurement error ≤±1 mm, and complete suppression of steam interference.

After six months of continuous operation, the radar level meter exhibited no signal drift or false readings. The sugar plant reported improved condensate discharge control accuracy, about 8% reduction in steam consumption, and extended maintenance intervals from monthly to quarterly, enhancing both operational efficiency and maintenance economy.

Advantages

- High Reliability: Stable and continuous level measurement under high-temperature steam environments.

- Low Maintenance: Non-contact measurement eliminates mechanical wear and buildup.

- Energy Efficiency: Optimized condensate level control reduces steam waste.

- Easy Integration: Fully compatible with DCS/PLC via HART or Modbus communication.

Customer Feedback

“The JWrada® radar level meter performs extremely reliably in our sugar boiling condensate system. Even under high steam concentration and temperature fluctuations, the signal remains stable and accurate. The condensate pump now operates automatically, significantly reducing manual inspections.”

Application Expansion

Beyond sugar boiling condensate equalizing tanks, JWrada® radar level meters are widely applied in:

- Sugar syrup and crystallization tanks

- Condensate return systems in food heating equipment

- Chemical steam condensate and boiler return systems

- CIP/SIP cleaning process level monitoring

With its advanced high-frequency radar technology and steam-interference immunity, JWrada® has become a trusted local alternative to imported brands such as VEGA and E+H.

Conclusion

Liquid level measurement in sugar boiling condensate equalizing tanks is vital for both energy efficiency and safety control. The JWrada® 80GHz radar level meter by Jiwei Automations provides a high-performance, low-maintenance solution through its non-contact high-frequency measurement, steam-interference suppression, and international safety compliance.

This case demonstrates that China’s high-end instrumentation can fully match the performance of imported products, delivering reliable operation, reduced maintenance costs, and enabling intelligent, digitalized process management for modern sugar manufacturing.