Reliable Performance of Jiwei Vibrating Fork Level Switch in Acidic Fluorinated Pipelines

01. Process Background: Acidic Medium + Fluorinated Piping + Continuous Operation

In acidic medium transport and storage applications, level measurement is not an auxiliary function but a critical safeguard to prevent pump dry running, tank overflow, and leakage incidents. Especially under strong corrosive conditions and space-constrained layouts, level switches must operate reliably without false alarms, adhesion interference, or vibration-induced failures.

This case comes from a chemical enterprise in Shandong, China, where the acidic material transport system is fully lined with fluoropolymer, including pipelines, valves, pump outlets, and tank interiors. Multiple types of level switches were previously deployed, but the system frequently faced probe corrosion, false alarms, and shortened maintenance cycles. After comparing several similar products, the enterprise ultimately selected Jiwei vibrating fork level switches as key liquid level monitoring devices, achieving long-term stability in operation.

The level switch points include:

- High and low level alarms in storage tanks

- Liquid detection at pipeline vent points

- Pump inlet dry-run protection

These points are interlocked with control logic and are critical to safe operation. False alarms may cause unnecessary shutdowns, while missed detection could lead to pump dry-running, tank overflow, or leakage. Therefore, devices must maintain high stability and long-term reliability.

02. Issues with Previous Level Switches

Before applying the Jiwei vibrating fork level switches, the site relied on low-end products that initially met basic detection needs. Over time, as acidic concentrations, circulation speeds, and production pace increased, limitations became apparent:

- Insufficient corrosion resistance: Sealing interfaces and probe structures deteriorated under acid exposure.

- Reduced operational stability: Frequent maintenance was required, and devices were sensitive to electromagnetic interference (EMI) during pump start/stop, resulting in occasional false alarms.

- Weld cracks in low-end forks: Leading to reduced probe strength and potential failure risk.

- Adhesion issues: Acidic medium with impurities caused thin deposits on probes, resulting in signal hysteresis or delayed alarms.

- Installation sensitivity: Some switches were installation-angle dependent, which was problematic in constrained spaces.

- Shortened maintenance cycles: Originally planned for six-month intervals, actual inspection was needed every two to three months, increasing costs and downtime risk.

To address these issues, the enterprise decided to adopt level switches suitable for corrosion, adhesion, vibration, space-constrained installation, and EMI-prone conditions.

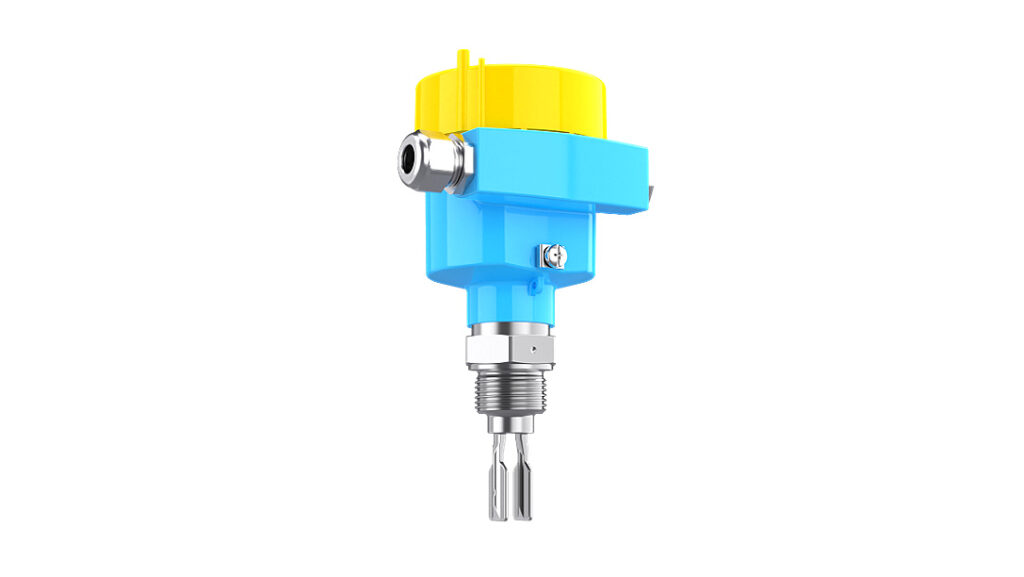

03. Jiwei Vibrating Fork Level Switch Solution

Jiwei vibrating fork level switch was selected for tank storage, pump inlets, and pipeline vent points. The switch determines liquid or gas phase based on fork vibration frequency changes, outputting clear ON/OFF signals unaffected by analog drift, ensuring intuitive and reliable operation.

- Corrosion resistance: The probe material withstands long-term acid exposure, with no pits or structural fatigue, avoiding premature failure.

- Adhesion tolerance: Even with thin surface deposits, the switch maintains accurate detection, eliminating false or delayed alarms.

- Vibration and EMI immunity: Internal vibration-based detection is unaffected by external vibrations. The switch operates reliably near pump zones or pipeline bends and resists EMI from motor startup, variable frequency drives, or high-power equipment.

- Flexible installation: Compact probe design allows horizontal, vertical, or side-mount installation, suitable for constrained spaces and fixed fluorinated interfaces.

- Low maintenance: No moving parts, no calibration required, long service intervals, ideal for continuous operation.

Overall, Jiwei vibrating fork level switch provides stable, clear, and reliable level alarm output, ensuring dependable system interlock logic even under vibration, adhesion, and EMI-challenged conditions.

04. User Feedback

After more than six months, the customer reported that Jiwei vibrating fork level switches perform stably and reliably, significantly improving previous system deficiencies. A technical engineer commented:

“The biggest change is that we no longer see unexplained alarms. When an alarm occurs, we address it directly without doubt.”

Inspection records show nearly zero false alarms, with accurate switch status, especially at pipeline vent points. Maintenance cycles have been extended: inspections that previously occurred every three months now take place every six months or longer. Probes show no corrosion or structural fatigue, reducing spare parts consumption and downtime. Clear liquid signals ensure stable pump start/stop interlocks, eliminating false trips, and enhancing operational continuity.

Additionally, the switches’ EMI resistance ensures signal stability near motors, variable frequency drives, and high-power equipment, further securing liquid level monitoring reliability.

05. Engineering Value

Safety: High level alarm reliability reduces false shutdowns, tank overflow, and pump dry-running risk, making acidic material transport more controllable.

Economics: Extended probe life, reduced maintenance, fewer spare parts, and decreased downtime lower overall operating costs.

Management: Less frequent manual verification, simplified operation, and improved system efficiency and automation.

Customer summary:

“The ON/OFF signal is straightforward, stable, and worry-free.”

Conclusion

Acidic, fluoropolymer-lined transport systems demand level detection devices that are corrosion-resistant, adhesion-tolerant, vibration- and EMI-proof, installation-flexible, and stable in operation. Jiwei vibrating fork level switches demonstrate these capabilities, overcoming traditional switches’ limitations in corrosion, adhesion, and installation constraints, enabling reliable, long-term liquid level control.

Going forward, Jiwei will continue to focus on corrosive liquid transport applications, providing users with robust, simple, and dependable level alarm solutions, making level monitoring a certainty rather than a potential risk.