Working Principle of Tuning Fork Level Switches

1. Introduction to Tuning Fork Level Switches

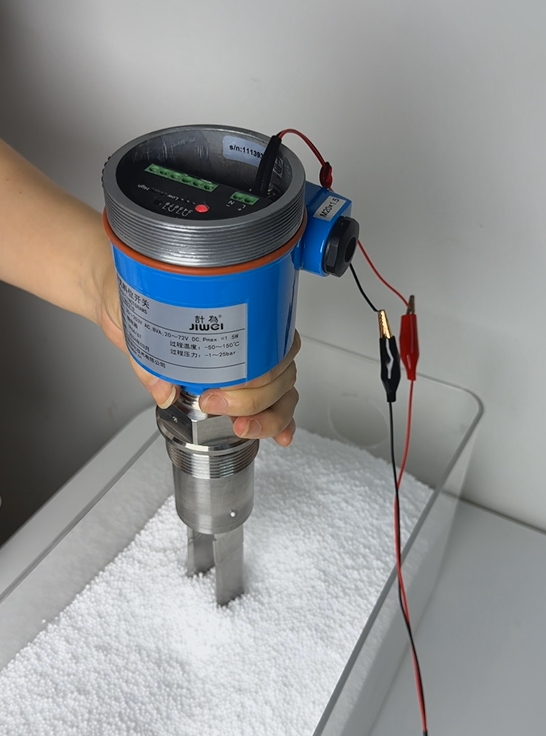

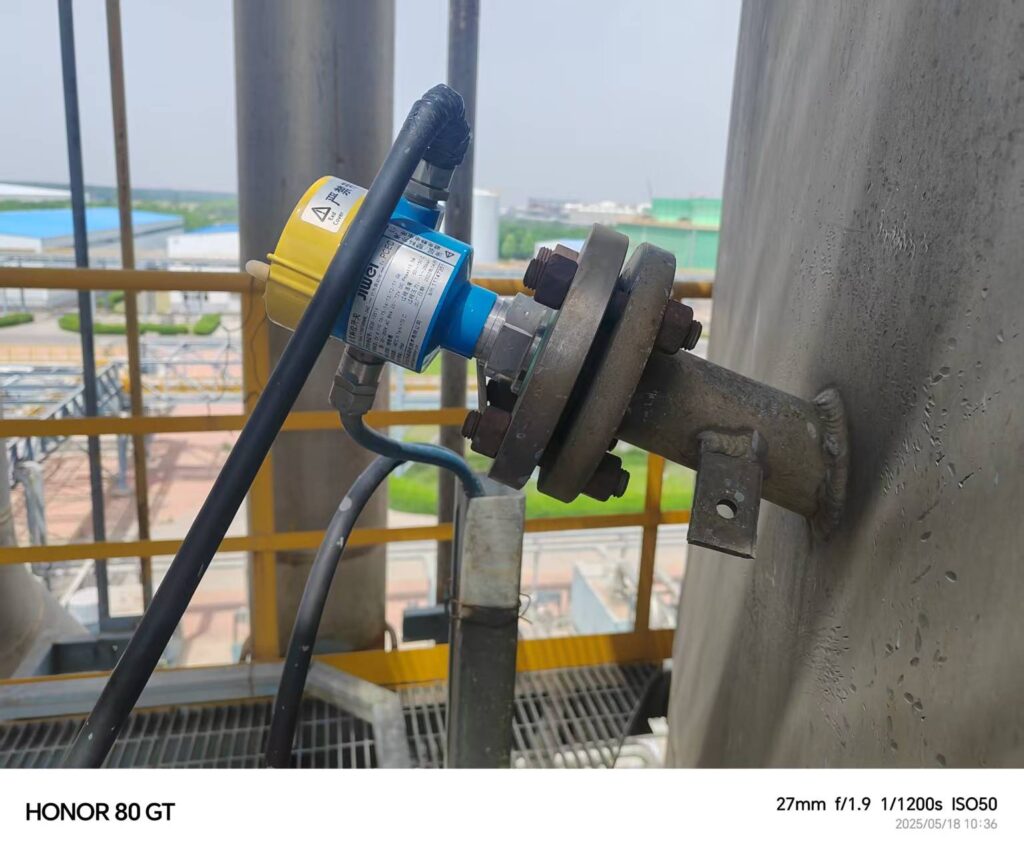

Tuning fork level switches are mechanical vibration-based instruments specifically engineered for solid level measurement in industrial processes. These devices are widely used in metallurgy, building materials, chemical, and food industries to detect the presence or absence of powdered or granular materials in silos, hoppers, and storage bins. With their simple structure, stable performance, long service life, and strong resistance to interference, tuning fork level switches have become mainstream solutions in process automation.

The core function of a tuning fork level switch is to detect whether material is present at a certain point and to output a switching signal to trigger alarms or automated control actions, ensuring safety and process efficiency.

2. Working Principle of Tuning Fork Level Switches

The key components of a tuning fork level switch include a resonating fork and a pair of piezoelectric crystals mounted at the fork base. These crystals serve as both the excitation and sensing elements.

2.1 Piezoelectric Excitation and Fork Vibration

When an alternating voltage is applied to the piezoelectric crystal, it causes the tuning fork to vibrate at a specific frequency—usually between 100Hz and 150Hz. In the case of Jiwei’s Fork-11 tuning fork level switch, the resonant frequency is approximately 138Hz.

2.2 Damping Response upon Material Contact

In free air (no material present), the fork vibrates with maximum amplitude and at a stable frequency. However, when the fork comes into contact with solid or powder materials, damping occurs. This damping reduces both the vibration amplitude and slightly alters the frequency—indicating the presence of material.

2.3 Signal Detection and Intelligent Processing

The piezoelectric sensor detects changes in vibration and converts them into electrical signals. These signals are then sampled, amplified, filtered, and analyzed by internal intelligent circuitry. If the amplitude drops below a preset threshold, the circuit outputs a switch signal—typically via relay contact—to inform the control system and initiate appropriate actions.

3. Technical Advantages of Fork-11 Tuning Fork Level Switch

3.1 High Sensitivity for Powder and Granular Materials

Jiwei’s Fork-11 features an optimized fork structure and piezoelectric design, enabling ultra-high sensitivity. It can detect solids with bulk densities as low as 0.008 g/cm³, making it ideal for fine powders, light granules, and bulk solids. This performance far exceeds conventional tuning forks which struggle with such low-density applications.

3.2 Superior Interference Immunity

Unlike low-cost “universal” models marketed as suitable for both liquids and solids, Fork-11 is built exclusively for solid level measurement. It filters out false signals caused by mechanical vibrations, dust accumulation, and electromagnetic interference. Even in extremely dusty or vibrating environments, Fork-11 maintains stable and accurate operation.

3.3 Robust and Durable Design

Constructed from high-grade 316L stainless steel, the Fork-11 resists corrosion, high temperatures, and dust ingress. Its rugged housing makes it suitable for deployment in harsh environments such as cement plants, metallurgical factories, and chemical facilities.

3.4 Easy Installation and Maintenance-Free Operation

The device is designed for quick integration into existing hoppers and silos. No calibration is needed after installation. With built-in diagnostics and smart self-check functions, Fork-11 offers plug-and-play operation, reducing downtime and minimizing maintenance costs.

4. Application Fields of Jiwei Fork-11

- Metallurgy: Powder and pellet storage bins, high-temperature environments

- Building Materials: Cement, lime, gypsum raw material silos

- Chemical Industry: Powder measurement and handling in corrosive atmospheres

- Food Industry: Grain, feed, flour storage level detection

- Environmental Systems: Waste management and dust control monitoring

5. Competitive Advantages Compared to Imported Brands

Compared with leading international brands (e.g., VEGA, Endress+Hauser), Jiwei Fork-11 demonstrates exceptional competitiveness in both performance and cost.

| Feature | Imported Brands | Jiwei Fork-11 |

|---|---|---|

| Minimum Detectable Density | ~0.03-0.05 g/cm³ | 0.008 g/cm³ |

| Interference Resistance | Moderate | Strong (anti-dust, anti-vibration) |

| Application Target | Solids & Liquids | Solids Only (powder/granules) |

| Durability | Good | Excellent (316L steel) |

| Price | High | Cost-effective |

| After-sales Service | International delays | Local support, fast response |

Fork-11 does not compromise like generic models. It is engineered specifically for solid applications, not a one-size-fits-all switch for both liquids and powders—ensuring reliability where it matters most.

6. Smart Features and Future Development

Jiwei is actively enhancing the Fork-11 product line by integrating smart manufacturing features. The roadmap includes:

- IoT compatibility

- Remote status monitoring via mobile app

- Predictive maintenance and fault diagnostics

- HART and Modbus communication protocols

These upgrades will align Fork-11 with Industry 4.0 and digital factory initiatives.

7. Conclusion: Setting a Benchmark for Solid Level Measurement in China

Tuning fork level switches remain an essential tool in modern industrial automation, especially for solid level detection. Jiwei’s Fork-11 tuning fork level switch leads this segment through its specialized design, outstanding sensitivity, and strong anti-interference capability.

By refusing to follow the “universal” liquid-solid hybrid approach, Jiwei delivers a professional-grade, application-specific solution that meets the highest industrial standards.

As China pushes forward in domestic instrumentation and smart manufacturing, Jiwei Fork-11 stands as a benchmark in solid level measurement—reliable, accurate, and proudly made in China.