What is the Working Principle of Radar Level Meters?

What is a Radar Level Meter?

A radar level meter is an industrial instrument that uses microwave echo ranging technology for non-contact liquid level measurement. It is widely applied in tanks, reactors, reservoirs, silos, and other containers. Compared to traditional ultrasonic, magnetic flap, or float level meters, radar level meters offer higher accuracy, longer lifespan, and are less affected by changes in temperature and pressure of the measured medium.

Core Working Principle of Radar Level Meters

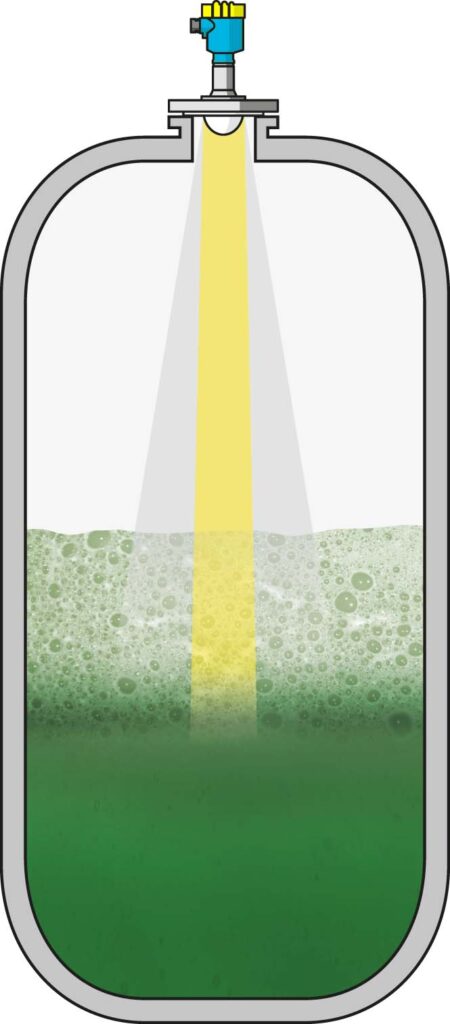

The basic measurement principle of radar level meters follows a “transmit-reflect-receive” process:

- The transmitter emits high-frequency microwave pulses (typically at 26GHz or 80GHz) downward.

- When the microwave hits the surface of the measured medium (liquid, solid, slurry, etc.), part of the energy is reflected back.

- The receiver captures the reflected signal and measures the time interval between transmission and reception.

- The system calculates the distance by using the electromagnetic wave propagation speed (approximately the speed of light), then converts it into a liquid level value.

Formula:

Level = Tank Height – (Echo Time × Electromagnetic Wave Speed ÷ 2)

This method offers very high response speed and measurement stability, making it suitable for harsh conditions such as high temperature, high pressure, steam presence, foam layers, and turbulent mixing.

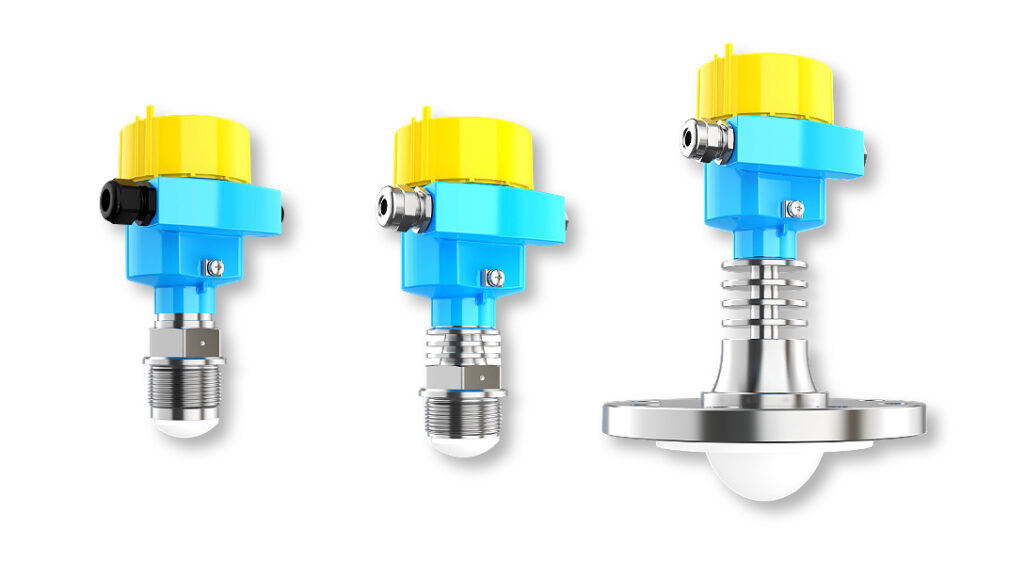

Types of Radar Level Meters

Radar level meters can be categorized based on their technology and signal type:

- Pulse Radar Level Meters:

Use short microwave pulses with low power consumption and simple structure, suitable for medium accuracy measurements. Common frequencies include 6GHz and 26GHz. - Frequency Modulated Continuous Wave (FMCW) Radar:

Employs 80GHz FMCW technology for higher measurement precision, narrower beam angle (≤3°), and stronger interference resistance. Ideal for challenging scenarios like stirred reactors, high-foam tanks, and narrow nozzles. - Guided Wave Radar (GWR):

Microwave signals travel along a metal probe or cable, suitable for liquids with low dielectric constants (e.g., liquid ammonia, liquid nitrogen), but less suitable for highly corrosive environments.

Technical Advantages of Radar Level Meters

| Advantage | Description |

|---|---|

| Measurement Accuracy | Up to ±1mm, surpassing ultrasonic and magnetic flap meters |

| Installation and Maintenance | Non-contact installation, no need for shutdown or tank opening, reducing maintenance costs |

| Interference Resistance | Unaffected by steam, dust, foam, and temperature variations |

| Wide Application Range | Suitable for liquids, solids, slurries, and viscous materials |

| Long Service Life | No moving parts; operational lifespan exceeding 10 years |

Factors Affecting Measurement Performance

Key factors influencing radar level meter accuracy include:

- Dielectric Constant of Medium:

Higher dielectric constants produce stronger echo signals for more stable measurement. Media with dielectric constants below 1.5 (e.g., liquid ammonia, liquid nitrogen) require guided wave radar or specialized calibration. - Installation Location:

Avoid mounting near feed inlets, agitators, or metal structures to prevent multi-echo interference. - Antenna Structure and Material:

Materials such as PTFE, polypropylene (PP), and 316L stainless steel, and shapes like horn, rod, or parabolic antennas, should be chosen based on specific environmental conditions.

Typical Applications

- Petrochemical Storage Tanks:

Monitoring crude oil, gasoline, ethanol, requiring explosion-proof certifications. - Food and Beverage Industry:

Measuring syrup, beer, dairy products, compliant with hygiene standards. - Water Treatment Plants:

Level monitoring in sewage basins, sedimentation tanks, and inlet/outlet channels. - Pharmaceutical and Renewable Energy:

High corrosion resistance and precise level control in extreme temperature and confined space scenarios.

Jiwei JWrada®: The Leading Domestic Radar Level Meter Brand

Among domestic manufacturers, Jiwei Automations’ JWrada® high-frequency radar level meter stands out for its excellent technical performance and adaptability across industrial projects.

Key Features of JWrada® 80GHz Radar Level Meter

- Advanced Technology:

Utilizes 80GHz FMCW for strong penetration and stable distance measurement. - Precise Identification:

Narrow beam angle (~3°) combined with multi-echo recognition algorithms to avoid false echoes. - Wide Application:

Effectively works in environments with foam, steam, mist, strong corrosion, and limited installation space. - Rich Functionality:

Supports Bluetooth remote configuration via the “Jiwei Smart Control” app for easy operation and maintenance. - Comprehensive Certification:

Meets multiple safety certifications suitable for industries with high safety standards. - Trusted by Major Projects:

Deployed widely in Sinopec, China Resources Power, Zhangjiang Pharma Valley, Environmental Parks, and other key industrial zones.

Conclusion

As industrial automation and smart manufacturing continue to advance, radar level meters, as essential non-contact measurement devices, will see broader application. Understanding their working principles and technical differences helps in accurate device selection and significantly improves project safety and efficiency.

If you seek cost-effective, reliable domestic radar level meters, Jiwei JWrada® is your trusted partner. Regardless of your industry—petrochemical, pharmaceutical, water treatment, or food and beverage—Jiwei offers expert selection guidance and localized technical support.

For more technical information, application cases, or selection advice, please visit:

📧 info@jiweimeter.com

📞 +86-755-28407683