New Level Monitoring Solution for Biogas Slurry Tanks: Ring-11 Vibrating Fork Level Switch + JWrada® Radar Level Meter

Industry Background and Application Scenario

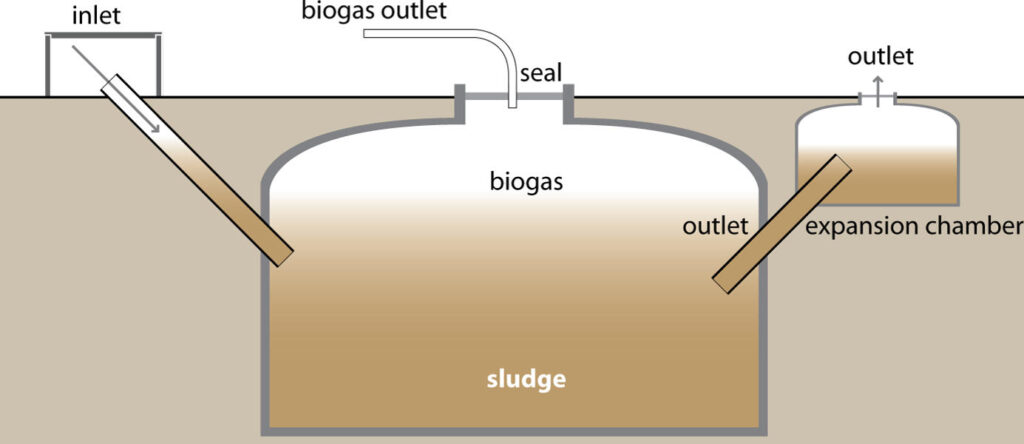

In the biomass and renewable energy sector, biogas projects have become a key technological pathway for the resource recovery of livestock and agricultural waste. Liquid manure, organic agricultural residues, and corn silage undergo anaerobic fermentation, which not only reduces environmental pollution risks but also continuously produces biogas for power generation, heating, and energy recovery.

In biogas production processes, slurry tanks and fermentation tanks play critical roles in raw material storage, mixing, fermentation, and intermediate buffering. The liquid level in these tanks directly affects fermentation efficiency, system safety, and overall energy performance. Therefore, real-time and reliable monitoring of slurry tank liquid levels is a fundamental requirement for the long-term stable operation of biogas projects.

Biogas Medium Characteristics and Measurement Challenges

Biogas slurry is a typical heterogeneous, multi-phase medium, whose physical and chemical properties change continuously during operation:

- The medium contains liquid, organic solid particles, and gas bubbles.

- High viscosity and poor flowability, prone to forming deposits on tank walls and instrument surfaces.

- Gas generation during fermentation causes significant liquid surface fluctuations.

- Density, conductivity, and dielectric constant vary across different feeding stages.

These characteristics make level measurement in slurry tanks a long-standing technical challenge in the biogas industry.

Limitations of Traditional Measurement Methods

In some early biogas projects, slurry tank level monitoring relied on float, mechanical, or conventional capacitive level switches. However, under long-term continuous operation and complex medium conditions, these methods exposed clear limitations:

- Float switches are easily obstructed by viscous slurry and organic deposits, leading to delayed or failed operation.

- Mechanical level devices, with moving parts, suffer accelerated wear and aging in high-humidity, high-corrosion environments, limiting their lifespan.

- Conventional capacitive switches are highly sensitive to medium dielectric changes, causing frequent false alarms when feed composition or fermentation conditions vary.

These issues increase system maintenance frequency and costs and may lead to overflow, pump dry-run, and other operational risks, threatening the safety, continuity, and stability of biogas plants.

Measurement Requirements and Technical Specifications

For this biogas project, the client required precise and reliable level measurement for the slurry tanks:

- Measurement objects: Slurry tanks / fermentation tanks

- Medium: Liquid manure, organic agricultural residues, corn silage slurry

- Measurement functions:

- High and low level alarms (overflow prevention, pump dry-run protection)

- Continuous level monitoring for process control and operational analysis

- Process conditions: Temperature +35 … +38 ℃, near atmospheric pressure with local micro-positive pressure

- Operational goals: Long-term maintenance-free operation, high reliability, adaptability to medium variations

Jiwei Overall Level Measurement Solution

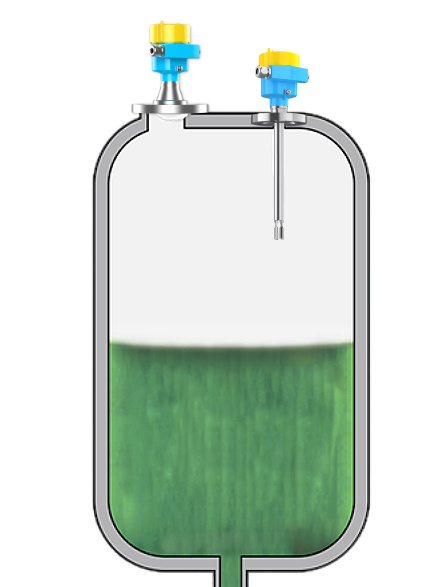

To address these complex conditions, Shenzhen Jiwei Automations Ltd provided a validated combination solution:

Ring-11 Vibrating Fork Level Switch

- Serves as a critical point-level detection device for high/low alarms, ensuring overflow protection and pump dry-run prevention.

JWrada® Radar Level Meter

- Provides continuous level measurement, supplying real-time data to support fermentation process control and material handling management.

These two instruments complement each other functionally and are clearly divided in application, forming a complete system integrating safety interlocks and continuous process monitoring.

Advantages of Ring-11 Vibrating Fork Level Switch

The Ring-11 operates based on changes in vibration frequency. When the fork is in air, it vibrates at its natural frequency; when covered by liquid, the damping effect of the medium alters the vibration frequency and amplitude, enabling reliable level detection and stable switch output.

Advantages in slurry tanks:

- Insensitive to medium property variations

- Detection does not rely on medium density, conductivity, or dielectric constant, making it suitable for liquid manure, organic residues, and mixed slurry, avoiding false alarms due to medium changes.

- High resistance to fouling and deposit formation

- Continuous high-frequency micro-vibration of the fork disrupts deposit formation, reducing delayed or failed operations caused by buildup.

- Simplified installation and commissioning

- No onsite calibration required; installation is straightforward, reducing complexity and errors.

- Robust structure suitable for harsh environments

- No external moving parts; resilient to high humidity and corrosive gases, ensuring continuous operation with minimal maintenance.

Typical applications:

- High-level alarm: prevent overflow

- Low-level alarm: prevent pump dry-run or abnormal feeding

Advantages of JWrada® Radar Level Meter

The JWrada® radar level meter is the only radar level meter in China that supports remote firmware upgrades and online engineer-assisted commissioning, designed for complex conditions and large-volume tanks. Both hardware and software are independently developed by Shenzhen Jiwei Automations Ltd, with algorithms optimized to suppress false echoes, interference signals, and foam disturbances, ensuring high stability and reliability.

Core advantages:

- Reliable continuous level data: real-time trends and process data support fermentation control, material handling, and operational analysis.

- Self-developed software and algorithms: intelligently identify liquid surface signals, suppress foam, vapor, noise, and reflection interference.

- Remote upgrade and online engineer assistance: via Jiwei’s “Jiwei Smart Control®” WeChat mini-program and official app, enabling firmware updates and parameter adjustments remotely.

- Non-contact measurement, corrosion and fouling resistant: high-frequency radar signal avoids physical contact, suitable for slurry, sludge, and corrosive media.

- Adaptable to complex liquid surfaces: excellent performance against foam, vapor, and agitation, suitable for high tanks and large-volume storage, meeting biogas, wastewater, and industrial level monitoring needs.

Project Results and Customer Benefits

Since commissioning, the Ring-11 vibrating fork level switch and JWrada® radar level meter system has demonstrated long-term stability and reliability:

- Improved operational safety: high and low level alarms and continuous monitoring prevent overflow and pump dry-run, ensuring uninterrupted fermentation operation.

- Reduced maintenance workload: the fork’s self-cleaning vibration and radar non-contact measurement minimize manual cleaning and recalibration.

- Efficient operation and maintenance: remote parameter adjustment and online commissioning enable rapid level alarm and measurement optimization, reducing downtime.

- Unified technical platform: shared signal interfaces and spare parts simplify monitoring, fault diagnosis, and operational control.

- Data-driven process optimization: continuous level data guides feeding adjustment, pump control, and process analysis, helping optimize fermentation parameters, increase biogas output, and improve overall system efficiency.

Conclusion

In the complex environment of biogas slurry tanks, level measurement faces challenges such as variable density, suspended solids, agitation, foam, and deposits. The core value lies not in extreme precision but in long-term stable and reliable operation.

The Ring-11 vibrating fork level switch combined with the JWrada® radar level meter provides a highly adaptive, field-validated solution:

- The Ring-11 fork offers strong fouling resistance and density adaptability for reliable high/low point-level alarms.

- The JWrada® radar meter, with high-frequency non-contact measurement and proprietary algorithms, avoids foam, vapor, and false echo interference, providing continuous level data for fermentation process control, feed adjustment, and process optimization.

This integrated solution allows real-time monitoring of slurry tank levels, prevents overflow and pump dry-run risks, supports operational decision-making, and enhances biogas production efficiency, system stability, and long-term reliability.

Jiwei level measurement solutions are not just instruments—they are the backbone of safe, efficient, and stable biogas plant operations.