Understanding Signal Drift: The Hidden Risk in Industrial Automation Systems

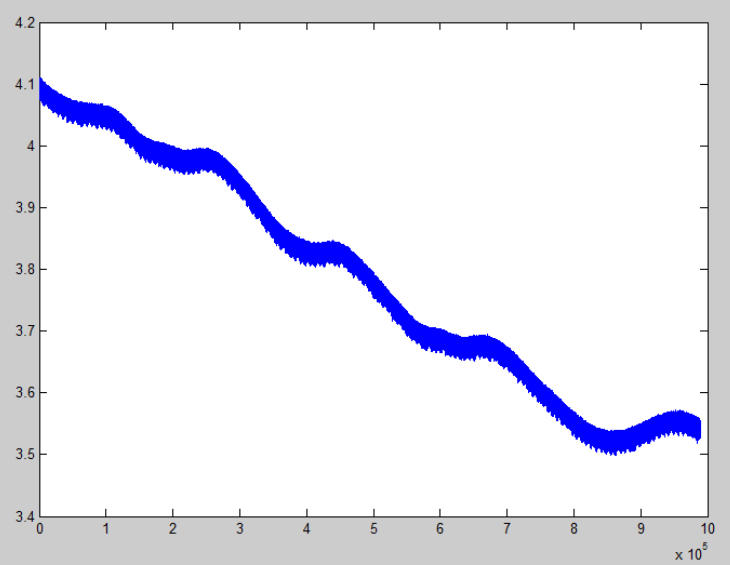

In industrial automation, there is an issue more frustrating than trips, more hidden than alarms, and more annoying than false actions—signal drift. It doesn’t trip the system, it doesn’t stop, it doesn’t show errors. It just slowly “drifts,” causing trends to slope, analog values to shift slightly, and PID controls to behave unpredictably.

Many engineers spend days monitoring trend charts, replacing instruments, checking programs, and testing terminals, only to conclude: the signal has drifted again. Signal drift is subtle—it doesn’t immediately stop equipment but gradually degrades system performance. Because it is invisible and does not trigger explicit alarms, it is often overlooked, becoming one of the most hidden risks in industrial plants.

This article aims to help engineers quickly understand: why signal drift occurs, why it is hard to trace, how to locate it fast, and how to solve it effectively. This is not basic theory but practical knowledge gained from years of field experience.

The Nature of Signal Drift: Slow Changes in the System

Most instrument failures are sudden: they break, they trigger alarms, or they fail. Drift is different. It is a gradual change—today a few milliamps off, a week later a few percent, a month later control becomes inaccurate, and after six months, trend charts are confusing.

Drift is hard to detect because it is rarely a problem with a single device; it often occurs at one or several points in the signal chain or even across the entire chain. This chain includes: instrument → transmitter → cable → terminal → isolator → PLC analog input → power supply → grounding → field environment → EMC interference. Any small change accumulates into drift, making it so tricky.

Common Causes of Signal Drift

- Ground potential difference causing zero-point inconsistency

The most typical and hard-to-detect source. When the PLC and instrument do not share the same reference ground, even a few tens of millivolts can shift the analog signal. Older plants often face this problem. Long-distance wiring worsens drift, while adding an isolator stabilizes the signal immediately. - Electromagnetic interference (EMI)

High-interference environments such as variable frequency drives, frequent motor starts, welding zones, or large switch power supplies can couple into analog signals. This does not create sudden errors but leads to continuous noise, small jagged trends, or occasional fluctuations. EMI contributes to about 40% of drift in industrial systems. - Cable and terminal issues

Old cables can absorb moisture, insulation degrades, terminals oxidize, and shielding breaks, causing slow signal drift. This is common but often overlooked. - Transmitter natural drift

Semiconductor sensors, pressure diaphragms, diffused silicon cores, thermocouples, and RTDs inherently drift over time. Temperature changes, mechanical stress, and aging seals contribute to slow deviation. Regular calibration is necessary. - Loose terminals or improper tightening

Vibration can loosen screws, and oxidation can degrade contact. Many engineers miss this simple cause. - Power supply instability

Ripple, voltage drops, shared circuits, and load changes can cause slow analog shifts. A stable 24V supply is essential.

How to Stabilize Signals: Focus on the Whole System

Drift results from overall instability: unstable zero points, reference grounds, power supply, cables, and instrument sensitivity. Ignoring drift can turn a controllable system into an uncontrollable one. The key is not to fix a single point but to optimize the entire chain. Practical steps include:

- Stable reference: Use isolators or isolated safety barriers to eliminate ground potential differences. This resolves 70% of drift causes.

- Control interference: Route analog cables away from power lines, use proper shielding, install EMC filters, and separate cable trays.

- Optimize wiring: Use industrial shielded cables, check terminal tightness, and avoid moisture exposure.

- Ensure power quality: Stable 24V power with minimal ripple is critical.

- Instrument management: Regular calibration controls natural drift within acceptable limits.

- Secure terminals: Use spring terminals in vibration-prone areas to prevent loosening.

Signal Drift as a System Health Indicator

Signal drift is not a failure; it is a warning. It indicates potential grounding issues, cable aging, EMI environment degradation, instrument wear, unstable power, or environmental changes. Older systems drift more frequently; stable systems drift less. Understanding drift means truly understanding the system.