Distillation Column Explained: Engineer’s Complete Guide

1. The Essence of Distillation: A Reverse Race Between Heat and Mass

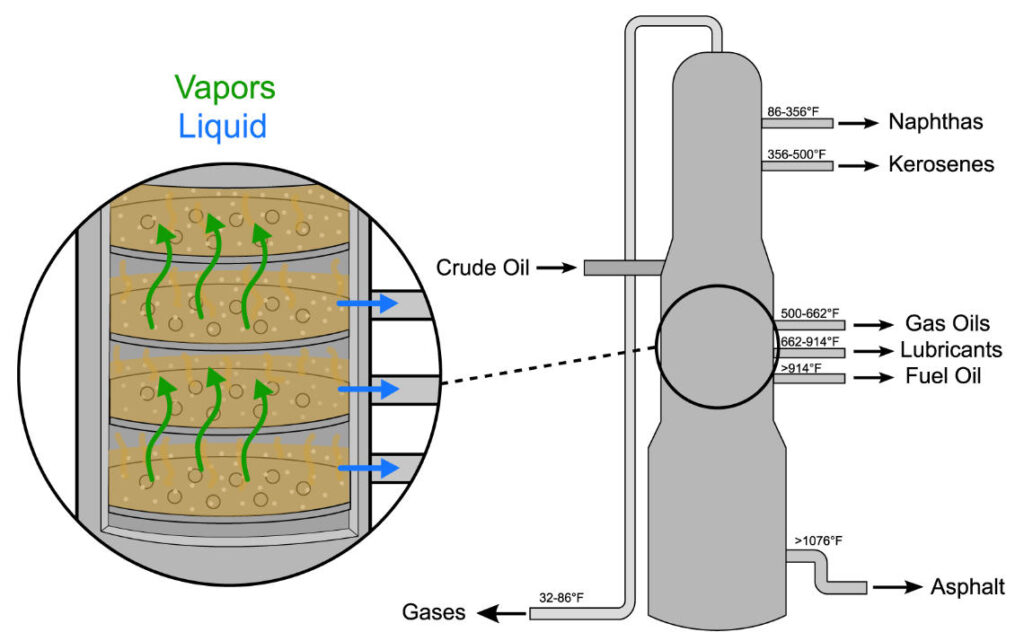

In chemical plants, the most demanding equipment for system-level understanding is not the reactor, but the distillation column. Its appearance is simple, yet it integrates four fundamental engineering domains: heat, mass, momentum, and control. Heating vaporizes the liquid and sends light components upward; condensation liquefies the vapor and sends heavy components downward. It is a “reverse distribution” process where heat moves upward and concentration moves downward: the top is cold, the bottom is hot; light vapor rises, heavy liquid falls; and at every tray or packing layer, the two phases establish a micro-equilibrium.

The engineer’s job is to keep this balance continuous, stable, and controllable. The purity and energy efficiency of gasoline, ethanol, pharmaceutical solvents, and electronic chemicals all depend on how well this column is “tuned.”

2. Structural Breakdown: Every Component Has a Purpose

A distillation column is composed of the reboiler, trays/packing, and the reflux system—each responsible for energy supply, mass transfer, and separation precision.

The reboiler is the energy engine. It provides the rising vapor that drives separation. It is typically heated by steam, thermal oil, or heat pump systems. Common field issues include temperature lag in the reboiler and fouling in heat exchangers.

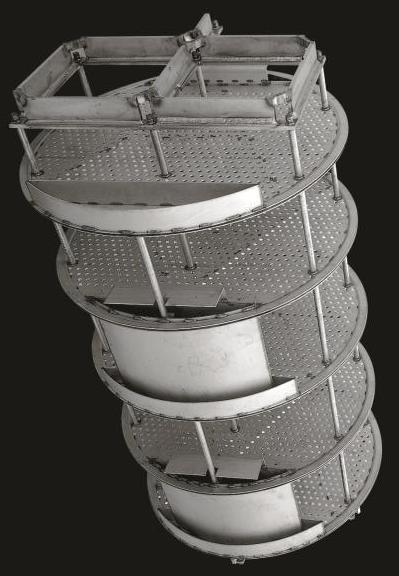

Trays and packing form the mass-transfer core where gas and liquid interact and reach equilibrium. Tray columns suit large throughputs, while packed columns are preferred for high-purity or low-pressure-drop systems.

The reflux system controls separation accuracy. Higher reflux improves purity but increases energy consumption; lower reflux saves energy but risks top-product fluctuations. Engineers must balance reflux ratio, energy use, and stability.

3. Engineering Logic of Startup and Commissioning

A distillation column typically transitions from cold start to steady operation through five stages:

- Pre-heating the reboiler

The entire system must warm up gradually and uniformly. - Building pressure and temperature gradients

Temperature should rise smoothly with no “inverted gradient” along the column. - Introducing feed

Feed temperature should be close to the theoretical feed condition to avoid disturbing the internal equilibrium. - Adjusting reflux

Start with a high reflux ratio, then gradually reduce to the design value while observing top temperature, bottom density, and condensate flow. - Reaching steady state

After several hours of stable operation with no major fluctuations, the column is considered stabilized.

The core principle is progressively establishing equilibrium, avoiding any sudden thermal or material disturbances.

4. Operating Abnormalities and Diagnostic Techniques

Common distillation column issues include flooding, weeping/dumping, and foaming/mist entrainment.

- Flooding

Symptoms: sudden rise in tray pressure drop, top-temperature oscillation.

Causes: excessive vapor velocity, high liquid load, tray blockage.

Action: reduce heat input, check reflux and liquid-level control, and relieve pressure if needed. - Weeping/Dumping

Symptoms: liquid fails to cover trays, vapor blows through; tower efficiency drops.

Causes: insufficient vapor load or low column pressure.

Action: increase vapor load, stabilize pressure, or increase reflux. - Foaming and entrainment

Symptoms: top product containing liquid, analyzer deviation.

Causes: liquid-surface disturbances or surface-tension changes (especially with surfactant systems).

Action: adjust liquid level, slow heating rate, or add antifoam agents.

Diagnosing a distillation problem ultimately means identifying which balance—thermal, material, hydraulic, or control—has been disrupted.

5. Energy Optimization: The Engineer’s Hidden Skill

Energy optimization does not simply mean “using less steam”—it requires systematic heat matching.

Heat integration can use condenser heat to preheat feed. Multi-column systems may adopt thermal coupling or even heat-pump distillation for major savings.

Pressure optimization reduces boiling points and improves energy efficiency, though overly low pressure increases vapor volume and equipment size constraints.

Advanced control—top-temperature feedback, reboiler-load feedforward, and reflux PID with fuzzy logic—can significantly improve disturbance resistance.

The essence of real energy savings is using heat where separation actually happens, not wasting it in ineffective zones.

6. Case Study: Optimization of an Ethanol Distillation System

A double-column ethanol system (50 tons/day) suffered from top-product fluctuations and excessive energy consumption.

Engineers identified cooling-water temperature swings causing condenser-control delays. They then replaced conventional PID with reflux-to-distillate ratio control and reconfigured the reboiler heat source to incorporate top-condensate heat recovery.

Results:

- Top-product purity stabilized at 99.8%

- Steam consumption reduced by 18%

- Three months of stable, fluctuation-free operation

The case demonstrates that distillation optimization is never a single tuning parameter—it is a rebalance of heat and material flows across the entire process.

Conclusion: A Chemical System That “Breathes”

A distillation column may appear static, but it performs tens of thousands of equilibrium interactions every second. Thermodynamics, fluid mechanics, process control, and material science all operate simultaneously inside the tower.

To make a column stable, efficient, and responsive—this is the craft of a chemical engineer.

The next time you walk through a plant and see that tall silver tower, remember: it is not merely a steel structure. It is a chemical system that thinks and breathes.