Understanding Explosion-Proof Electrical Equipment: The Difference Between IIA, IIB, and IIC Classifications

Explosion-proof electrical equipment refers to electrical devices that, under specified conditions, do not ignite the surrounding explosive atmosphere. Among the various explosion protection ratings, the classifications IIA, IIB, and IIC are the most commonly used. However, many people still struggle to differentiate between them. This article provides a clear and professional explanation of these classifications.

The hazard level of explosive mixtures is determined by four key factors:

- Explosive limits

- Flame propagation ability

- Ignition temperature

- Minimum ignition current

Based on the characteristics of these mixtures and the requirements of actual industrial processes, explosive environments are classified into three categories:

- Category I: Methane gas in underground coal mines

- Category II: Explosive gas mixtures (e.g., factory gases, vapors, mists)

- Category III: Combustible dusts (e.g., explosive dust, flammable fibers)

Category II refers specifically to explosive gas atmospheres other than those found in mines. This includes gases, vapors, or mists that may occur in industrial environments.

Further classification within Category II—into IIA, IIB, and IIC—is based on:

- Maximum Experimental Safe Gap (MESG)

- Minimum Ignition Current Ratio (MICR)

Hazardous Gas Group Classification and Electrical Equipment Selection

To ensure that explosion-proof equipment performs safely under specific explosive gas or vapor environments, the gases are categorized so that both flameproof (Ex d) and intrinsically safe (Ex i) devices are designed to match the group characteristics.

- Flameproof equipment: grouped by MESG

- Intrinsically safe equipment: grouped by MICR

(which compares the minimum ignition current of the gas to that of methane)

These classifications apply consistently to both hazardous gases and the equipment used in such environments.

- Group I: Equipment used in underground coal mines (methane atmosphere)

- Group II: Equipment used in non-mining explosive gas atmospheres

Within Group II, devices are further classified as:

- IIA: For gases with higher MESG and MICR values (e.g., propane)

- IIB: For moderate hazard gases (e.g., ethylene)

- IIC: For highly explosive gases with very low ignition energy (e.g., hydrogen, acetylene)

Note: Equipment marked IIC is suitable for IIA and IIB environments, while IIB-rated equipment is suitable for IIA.

Representative Gases and Application Scenarios

| Classification | Representative Gas | Typical Risk Level | Suitable Equipment Type |

|---|---|---|---|

| IIA | Propane | Low | IIA-rated devices |

| IIB | Ethylene | Medium | IIB-rated devices |

| IIC | Hydrogen, Acetylene | High | IIC-rated devices |

Explosion Group and Temperature Class Chart

To enhance safety in explosive environments, hazardous gases are classified not only by ignition characteristics but also by temperature groups. This allows proper matching of explosion-proof electrical equipment based on the ambient conditions and gas types.

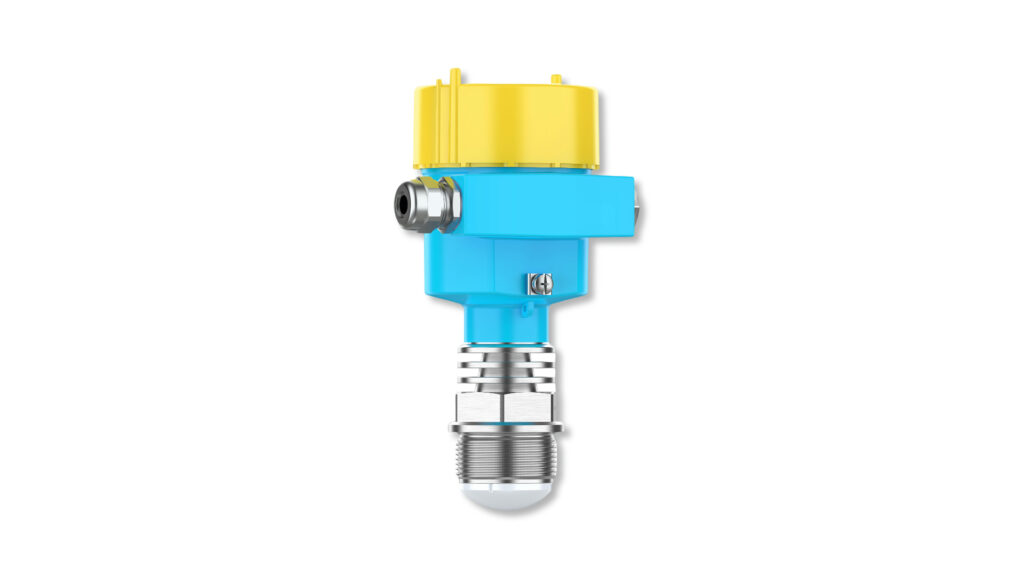

How to Choose a Radar Level Meter for Hazardous Environments

When selecting a radar level meter for hazardous environments, it’s critical to match not only the explosion-proof classification (IIA, IIB, or IIC) but also the specific site conditions. Key factors include:

- Process temperature and pressure

- Presence of vapors, mist, or flammable gases

- Certifications such as ATEX, IECEx, SIL2/SIL3

- Compatibility with flameproof or intrinsically safe enclosures

- Antenna sealing and non-sparking materials

For example, an 80 GHz radar level meter with a fully enclosed PTFE lens antenna and IIC-certified flameproof housing is ideal for hydrogen-rich reactors or solvent storage tanks.

Tip: Always consult both the gas classification and the application environment before selecting explosion-proof radar or ultrasonic level meters.

Conclusion

In industrial environments where explosive gases or vapors may be present, selecting the appropriate explosion-proof electrical equipment is a critical step to ensure personnel safety, equipment reliability, and regulatory compliance. The classification into IIA, IIB, or IIC groups is not arbitrary—it is based on scientific parameters such as:

- Explosive limits, which determine the concentration range within which gas mixtures may ignite

- Flame propagation capability, affecting how quickly flames can spread through enclosures

- Ignition temperature, which is the minimum temperature required to ignite the gas

- Minimum ignition current (MICR), which assesses how easily a gas can be ignited electrically

- Environmental risk levels, including the frequency and duration of hazardous atmosphere presence

Selecting explosion-proof equipment with the correct classification ensures that the device can operate safely under worst-case conditions. For instance, equipment rated for IIC environments must withstand the most demanding explosive risks and can also be safely used in IIA and IIB areas.

Furthermore, the choice of radar or ultrasonic level meters for hazardous applications should take into account not just the explosion-proof rating, but also other site-specific factors such as process temperature, chemical compatibility, signal attenuation due to mist or dust, and international certification standards like ATEX, IECEx, and SIL.

By integrating the correct classification with high-quality design and materials, industries can effectively minimize explosion risks, optimize operational efficiency, and ensure long-term safety and compliance in even the most hazardous gas environments.