UGG Factory Feeding System: Jiwei Vibrating Rod Level Switch Application

1. Project Background

The UGG footwear factory in Henan, uses Jiwei vibrating rod level switches to manage large-scale automatic handling of EVA (ethylene-vinyl acetate copolymer) and PU (polyurethane) materials for wool boots and related shoe products. These raw materials are stored in silos in powder or granular form and delivered via screw conveyors or pneumatic systems to mixers, molding machines, or outsole press machines.

In the traditional production model, feeding relied on manual monitoring and operator experience, leading to the following issues:

- Discontinuous feeding: When silo material levels were insufficient, the conveyor could not replenish in time, causing production downtime.

- Overfeeding: When levels were too high, continued screw conveying caused silo overflow or overloading of the mixer.

- Frequent manual intervention: Operators had to regularly check silo and feeding status, increasing labor intensity and management cost.

- Safety risks: Untimely or excessive feeding could lead to machine faults, dust dispersion, or material waste.

To resolve these challenges, the factory introduced Jiwei vibrating rod level switches to monitor level conditions in the automatic feeding system and achieve automated and safe operation.

2. Process and System Characteristics

The UGG shoe production process involves multiple outsole materials. The feeding behavior of EVA and PU materials has distinct characteristics:

Material Characteristics

- EVA: Light, easily powdered, granular, prone to dust dispersion during transport.

- PU: Hard particles, easily affected by static adhesion, creating risk of localized pipe blockage.

Feeding Methods

- Screw conveyor: Suitable for short-distance silo-to-mixer feeding, stable and easy to control.

- Pneumatic conveying: Suitable for long-distance pipeline feeding; requires precise level control to prevent idle running or overpressure.

System Requirements

- Continuous material level monitoring

- Automatic start/stop control

- Overflow and blockage prevention

- Dust and adhesion tolerance

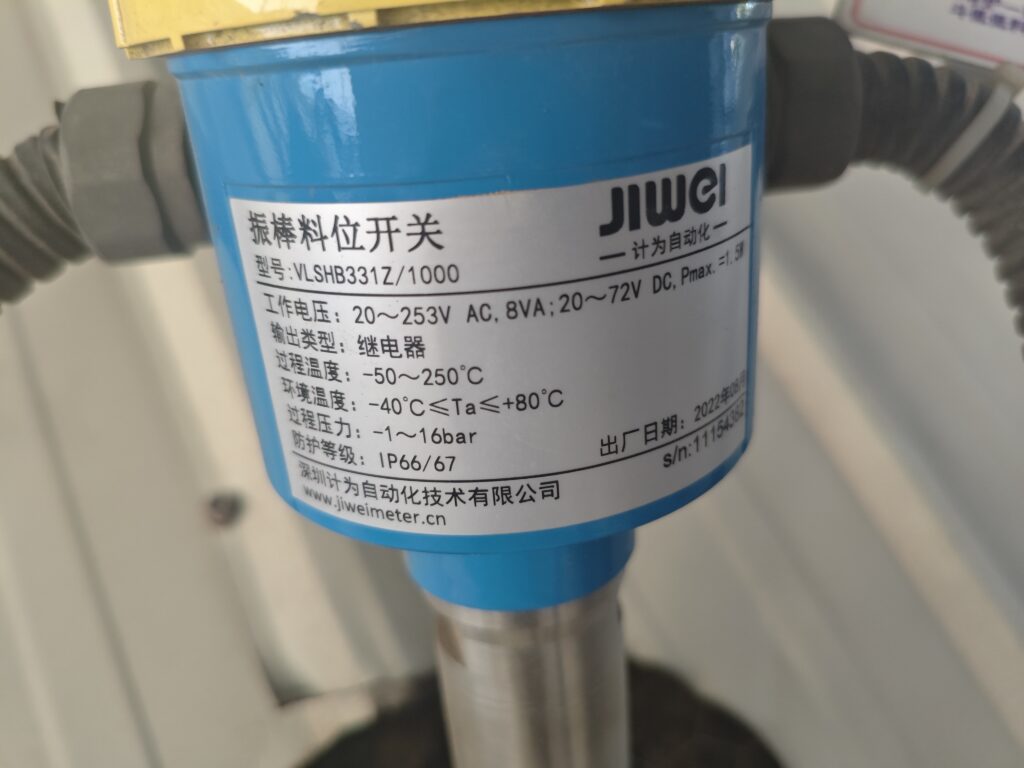

3. Jiwei Vibrating Rod Level Switch Solution

Based on process requirements, the factory installed Jiwei vibrating rod level switches at key silo and conveyor points. The solution includes:

High/Low Level Monitoring

- High-level switch prevents overfeeding.

- Low-level switch triggers automatic replenishment.

- Logic control: Low-level start → High-level stop → Stable zone control.

Anti-Adhesion Design

EVA and PU powders tend to adhere to probe surfaces. Jiwei vibrating rod level switches adopt a patented dual-rod structure with precision tuning, effectively preventing buildup. Even if a thin layer forms, the switch maintains reliable action without false alarms or delays.

Probe material is antistatic and dust-resistant, reducing maintenance effort.

Anti-Vibration & EMI Resistance

Screw and pneumatic systems induce vibration. Jiwei level switches detect level by vibration frequency rather than mechanical displacement, ensuring stable operation.

They are also EMI-resistant, maintaining stable signals near motors, VFDs, and high-power devices.

Installation Flexibility

Vibrating rod switches respond sensitively and support horizontal, vertical, or side mounting—ideal for silos with tight inlet clearance or dense pipework.

No system redesign or recalibration is required.

Maintenance & Service Life

- No moving parts

- No calibration

- Long service life

- Minimal downtime

- Reduced spare parts consumption

4. System Performance Outcomes

Since adopting Jiwei vibrating rod level switches, feeding system performance has improved significantly:

Automated Feeding

Low-level detection triggers conveyor startup, high-level detection stops feeding.

Continuous material supply reduces mixer or press machine waiting time, improving production efficiency.

False Alarms Sharply Reduced

Because the vibrating rod design is insensitive to powder adhesion, level signals are stable and accurate.

Operators no longer need to frequently inspect silos.

Extended Maintenance Cycles

Previously, level switches required monthly cleaning due to dust accumulation.

Now inspection is needed only once every six months or longer.

Improved Safety

Automatic logic prevents empty silo conditions, overflow, conveyor dry running, and downstream overload.

Higher Efficiency & Management Control

Level information integrates with automation systems and supports ERP/SCADA visualization.

5. Engineering Value and Summary

Safety Value

- Prevents conveyor dry running, overflow, and blockage

- Ensures stable downstream material supply

Economic Value

- Reduced labor and inspection costs

- Longer switch service life

- Increased feeding and production efficiency

Management Value

- Reliable interlock signals for automation

- Simplified operation

- Data-enabled production planning and inventory control

Conclusion:

Jiwei vibrating rod level switches have played a key role in the automatic feeding system at the UGG footwear factory in Xuchang. Through high/low level control, adhesion resistance, vibration and EMI immunity, and flexible installation, the system now achieves automated feeding, longer maintenance cycles, and improved production safety.

This case demonstrates that the right level switch selection can significantly optimize material supply and production management in footwear manufacturing—supporting the transition from manual dependence to intelligent automation.