From False Alarms to Accurate Monitoring: Vibrating Rod Level Switch in Polyester Chip Silos

Background and Industry Requirements

In the chemical fiber industry, polyester chips (also known as polyester pellets) are key intermediate materials used in the production of polyester fibers and PET bottles. Typically, these chips are stored in large silos or intermediate storage bins and transported to subsequent processes either via pneumatic conveying or gravity discharge. Reliable level measurement in these storage and conveying systems is critical to ensure continuous production and to prevent empty silo conditions or overflow incidents.

Polyester chips have several unique physical characteristics: they are lightweight, low in density, have a high angle of repose, and tend to carry air or generate dust during discharge. These properties make conventional level measurement instruments—such as capacitive switches, rotary paddle switches, or RF admittance switches—prone to sensitivity issues, false alarms, or even complete failure. Common challenges reported by clients include:

- Inaccurate full-silo detection: High-level points fail to trigger in time, leading to material overflow.

- Delayed low-level signals: Bottom-level detection may not activate promptly, causing equipment to run dry.

- Severe dust interference: Capacitive instruments are often affected by static and dust, requiring frequent maintenance.

Against this backdrop, clients urgently need a level switch that can reliably handle the specific conditions of polyester chip silos.

Client Communication and Requirement Confirmation

The client in this case is a chemical fiber enterprise in Eastern China, operating multiple production lines with an annual output of several hundred thousand tons of polyester. During initial discussions, the client outlined three core requirements:

- Accurately detect low-density pellet levels to avoid missed alarms.

- Maintain stable operation in high-dust environments, reducing false triggers.

- Reduce maintenance requirements and minimize manual cleaning frequency.

The Jiwei Automations engineering team introduced the Tube-11 Vibrating Rod Level Switch, explaining its operating principle: the probe continuously vibrates at high frequency, and when it comes into contact with material, the vibration is dampened, immediately triggering a switching signal. Because this principle does not rely on the material’s dielectric constant or conductivity, it is particularly effective for low-density pellets such as polyester chips.

In addition, the team referenced prior successful applications of Tube-11 in flour, starch, and lightweight plastic pellet silos, demonstrating consistent performance in low-density materials and providing the client with a tangible sense of its reliability.

Process Challenges and Solutions

The client faced several process challenges:

- Large silos with lightweight pellets: Both top-level (full) and bottom-level (empty) monitoring were required.

- Uneven material accumulation: Bridging inside the silo could cause local voids.

- High dust concentration: Dust generated during material feed often caused traditional capacitive switches to malfunction.

- Variable feed rates: Rapid or slow material flow led to delayed responses in some instruments.

To address these issues, Jiwei recommended the Tube-11 dual-rod vibrating rod level switch, offering the following advantages:

- High sensitivity detection: Capable of detecting materials with density as low as 20 g/L, ensuring accurate monitoring of lightweight pellets.

- Dual-rod patented probe: Specially designed to resist dust and static interference, providing excellent operational stability.

- High-temperature adaptability: Standard version operates up to 250 °C; optional air/water-cooled high-temperature version reaches 400 °C, suitable for extreme conditions.

- Built-in self-diagnosis: Enables precise fault identification, reducing maintenance costs and improving system reliability.

- Corrosion-resistant materials: Constructed with 316L and 318S13 stainless steels, ensuring long-term stable operation even in harsh environments.

- Anti-clogging capability: Minor material adhesion does not trigger false alarms, ensuring stable operation.

- Maintenance-free design: No periodic calibration required, simple installation, and long-term reliable performance.

Installation and Commissioning Process

During on-site implementation, Jiwei engineers worked closely with the client’s process staff:

- Top installation: Configured as a high-level alarm to prevent overflow when the material approaches the silo top.

- Bottom installation: Configured as a low-level alarm, signaling when material reaches the lower limit to avoid equipment running dry.

The commissioning team simulated various extreme scenarios:

- Rapid feeding: Large amounts of chips entered the silo instantly, and Tube-11 responded quickly without delay.

- Slow discharge: Material levels gradually decreased, with the probe maintaining a stable low-level signal output.

- Dust impact: During feed testing, the probe surface accumulated dust but did not trigger false alarms.

A small but memorable detail occurred during initial installation: the client was concerned that the probe might become “stuck” due to material accumulation. To test this, the team ran the silo at half-full capacity continuously for three days. The Tube-11 maintained normal vibration throughout, with no issues of sticking or false readings.

Operational Results and Client Feedback

Six months after commissioning, the client reported significant improvements:

- Alarms are extremely accurate; both rapid feeding and continuous discharge trigger signals at the correct points.

- Unplanned downtime due to missed or false alarms has decreased substantially, ensuring production continuity.

- Probe maintenance requirements have reduced significantly, relieving the workload of maintenance personnel.

- With high- and low-level alarms linked to the PLC, operations are safer, preventing dry running and material overflow.

The client summarized: “Tube-11 has completely eliminated the issues we faced with capacitive switches. It not only solved the monitoring problem for polyester chips but also significantly reduced our production risks.”

Comparison Table: Polyester Chip Challenges vs Tube-11 Solutions

| Process Challenge | Traditional Instrument Issues | Tube-11 Solution |

|---|---|---|

| Rapid top-level feeding | False alarms from capacitive switches | High-level rod switch triggers reliably |

| Bottom-level empty | Delayed alarms, dry running | Low-level rod switch outputs instantly |

| High dust | Frequent cleaning, false signals | Fully sealed probe, maintenance-free |

| Lightweight, high repose angle | Insensitive to material | High-sensitivity detection, anti-clog design |

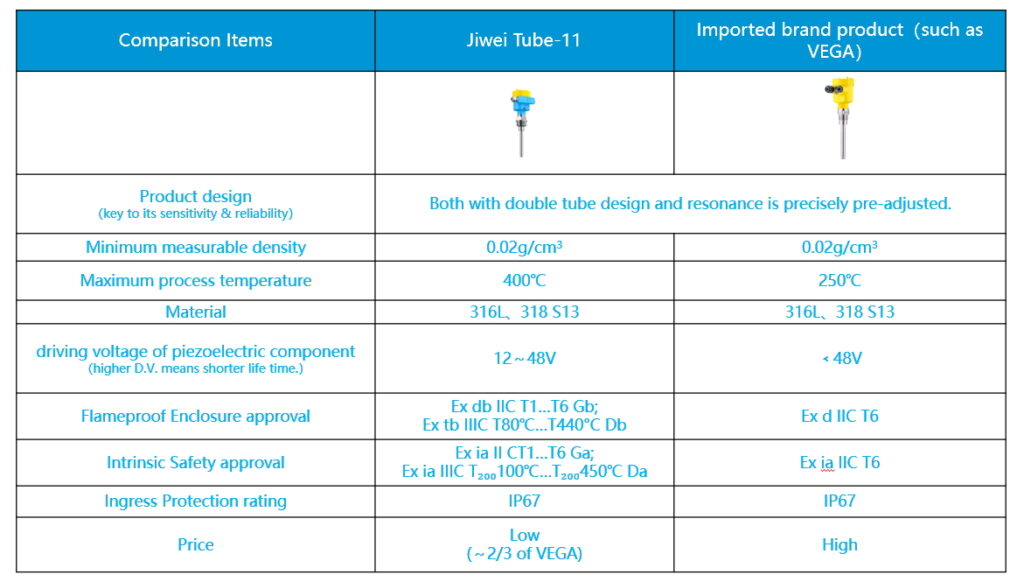

Tube-11 as an Ideal Vega Replacement

The Tube-11 vibrating rod level switch can serve as an ideal replacement for Vega products, offering stable performance even under low-density and high-dust conditions.

Industry Value

This case demonstrates that the Tube-11 vibrating rod level switch is highly adaptable to low-density pellet applications. It not only resolves long-standing monitoring challenges in polyester chip silos but also provides a reliable reference for industries handling flour, starch, and lightweight plastic pellets.

In the context of domestic replacement and high operational stability, Tube-11’s significance extends beyond a single project, providing a mature solution for the entire lightweight material storage and conveying process.

Conclusion

From this case, it is evident that the Tube-11 vibrating rod level switch delivered remarkable results in polyester chip silos:

- Effectively solved the instability issues in lightweight pellet detection.

- Significantly improved production line continuity and safety.

- Reduced maintenance costs, providing long-term value to the enterprise.

For polyester and similar industries, the Tube-11 is not just an instrument; it is a critical tool for ensuring production stability and operational safety.