Application of JWrada® Radar Level Meters in Modern Silo Management

In modern concrete batching plants, cement production facilities, and other bulk material processing factories, silo management is a critical factor affecting production efficiency and supply chain smoothness. To address the challenges of traditional manual inventory methods—which are time-consuming, labor-intensive, and prone to errors—Jiwei JWrada® radar level meters provide a high-precision, reliable, and low-maintenance solution for accurate silo monitoring. Issues such as material leakage, uneven settling, and climatic changes are effectively managed, enabling enterprises to plan replenishment efficiently, maintain production continuity, reduce logistics costs, and streamline supply chain management.

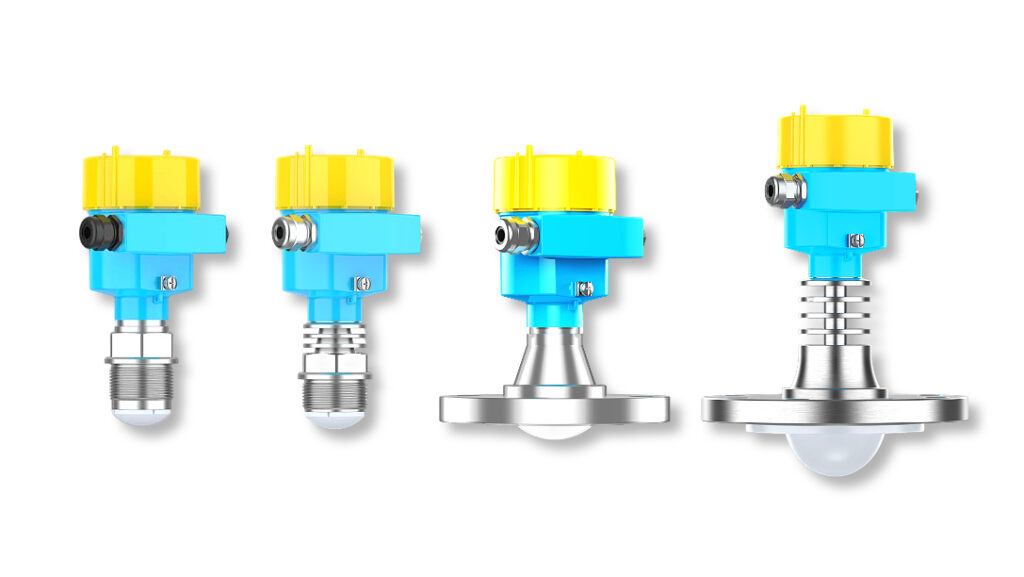

To address these challenges, companies require a high-precision, reliable, and low-maintenance level measurement solution. The Jiwei JWrada® 80GHz FMCW radar level meter was developed precisely for this purpose. Utilizing high-frequency Frequency Modulated Continuous Wave (FMCW) technology, it provides stable and reliable level measurements in complex environments, offering strong technical support for inventory management and supply chain optimization.

Jiwei JWrada® 80GHz FMCW Radar Level Meter: High-Precision, Reliable, Low-Maintenance Solution

Multi-Scenario Applications for Real-World Challenges

Cement and Aggregate Silos

Challenge: High dust concentration and uneven material stacking create blind spots, making traditional measurement devices unstable.

Solution: The 80GHz FMCW radar level meter features a narrow beam design and high-speed echo processing, accurately detecting material levels even in silo corners or on peak stacks, avoiding false signals and ensuring continuous reliable measurement.

Concrete Batching Plants

Challenge: Frequent material in/out flow and constantly changing cement and aggregate surfaces make manual recording error-prone and replenishment planning difficult.

Solution: Continuous non-contact measurement combined with the Jiwei Smart Control cloud platform enables real-time inventory monitoring and data recording, helping planners optimize material replenishment and transportation for smoother production and improved logistics efficiency.

Grain and Chemical Powder Storage

Challenge: Materials are prone to caking and uneven settling, high dust levels, and traditional equipment requires frequent maintenance.

Solution: Non-contact measurement prevents dust clogging, and intelligent filtering algorithms eliminate secondary reflection interference, providing stable and reliable material level readings.

Core Technical Advantages

High-Precision Measurement

Using 80GHz FMCW technology and advanced echo processing algorithms, the meter minimizes interference and accurately detects solid material surfaces. Even in dusty or complex piling conditions, it delivers stable and reliable readings.

Non-Contact Design

No mechanical contact eliminates wear, clogging, or material buildup, reducing maintenance frequency and downtime.

Intelligent Data Processing

Built-in echo analysis and filtering algorithms automatically detect the true material surface, eliminating multipath reflection and signal noise, ensuring reliable data.

Remote Management and Digital Integration

Through the Jiwei Smart Control platform, measurement data can be uploaded in real time to cloud or local control systems for remote monitoring and intelligent analysis. Operators can track inventory levels, material consumption rates, and remaining capacity without frequent on-site counting, allowing for scientific replenishment and production planning.

Multi-Material and Environmental Adaptability

Supports powders, granules, aggregates, and other materials. With IP68 or IP67 protection, suitable for indoor/outdoor, humid, or corrosive environments, meeting diverse industrial requirements.

Digital Management and Smart Replenishment

- Remote Control: Bluetooth configuration and remote data access enable monitoring without entering hazardous or dusty silos.

- Data Integration: Connects with ERP, MES, and other enterprise management systems for integrated inventory, production, and logistics scheduling.

- Trend Analysis: Historical data allows managers to predict material usage patterns, optimize replenishment frequency, and reduce waste or stockouts.

Real-World Case: Supply Chain Efficiency Improvement

A large concrete batching plant and its logistics partners significantly improved inventory and transportation management after implementing JWrada® radar level meters and the Jiwei Smart Control platform.

- Logistics Companies: Can plan delivery routes and schedules based on accurate inventory data, improving efficiency and reducing empty or repeated trips.

- Plant Operators: No longer need frequent manual inventory checks, allowing focus on production and scheduling, enhancing continuity and operational efficiency.

- Supply Chain Collaboration: Transparent data and visible workflows lower operational costs and increase customer satisfaction.

By combining JWrada® radar level meters with the Jiwei Smart Control platform, enterprises can achieve high-precision, non-contact measurement while leveraging digital management tools to optimize replenishment, improve inventory transparency, and enhance supply chain efficiency, ensuring production continuity and reducing operational costs in complex environments.