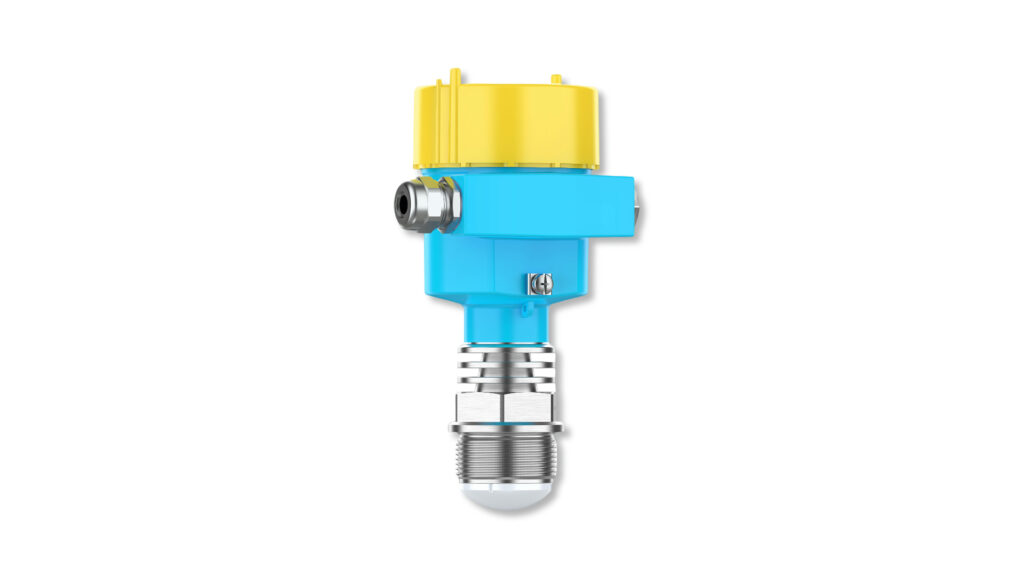

JWRada-32® Radar Level Transmitter for Underground Diesel Tanks – Reliable & Maintenance-Free

1. Project Background

The equipment center of an industrial park is equipped with multiple diesel generator sets for emergency power supply to production equipment. To ensure safe fuel storage while minimizing space occupation, the facility adopted two underground diesel storage tanks (15 m³ each) as the core fuel supply system. Due to long-term underground installation, tight tank sealing, significant temperature variations, and frequent vapor space changes, liquid level monitoring has been a major operational challenge.

Traditional mechanical level gauges faced several limitations:

- Difficult maintenance: Tanks are buried underground; opening the manhole risks water and debris ingress, making maintenance complex.

- Low reliability: Float-based gauges can stick, and vapors or volatile gases frequently cause reading fluctuations.

- Frequent manual inspections: At least one manual reading per shift, resulting in high workload.

- Inability to meet containment and remote monitoring requirements: Accurate remote monitoring and alarms were required to prevent spills and ensure safety.

To improve fuel management and reduce manual inspections, the customer selected the JIWEI JWRada-32® 80GHz FMCW (Frequency Modulated Continuous Wave) Radar Level Transmitter from Shenzhen Jiwei Automation Co., Ltd., enabling continuous, stable, and non-contact level measurement of the underground diesel tanks.

2. Operational Challenges and Measurement Requirements

Compared with aboveground tanks, underground diesel tanks pose higher demands for level measurement. The JWRada-32® radar level transmitter has been optimized for these challenging conditions:

Comprehensive Advantages

JWRada-32® delivers high reliability, strong anti-interference performance, and adaptability to complex installations and low-dielectric liquids. Its non-contact, high-frequency, high-precision design ensures safer, more stable tank level monitoring, while reducing maintenance costs and improving operational efficiency.

Underground Tank Structure and Humidity

Buried tanks typically have high internal humidity, and manholes often accumulate condensation, causing traditional probe or contact level gauges to fail due to corrosion or condensation. JWRada-32®’s non-contact radar technology avoids direct liquid contact, ensuring stable measurements in humid or condensing environments and reducing maintenance frequency and instrument failure.

Low Dielectric Liquid Measurement Challenge

Diesel has a low dielectric constant (≈2.1–2.3) and is highly volatile, which can weaken echo signals. Conventional radar or low-frequency devices often experience unstable readings or signal loss. JWRada-32® incorporates specialized signal processing algorithms to enhance echo detection of low-dielectric liquids, ensuring continuous and reliable level measurement even under low-reflection conditions.

Limited Tank Top Space

Manholes of underground tanks are typically only 400–500 mm in height, limiting space for conventional radar or probe level instruments. JWRada-32®’s compact design and short blind zone allow flexible installation without structural modifications, fitting within standard manhole openings.

Minimal Liquid Surface Fluctuation and Poor Lighting

Diesel in storage tanks has small surface fluctuations, low reflectivity, and no illumination. Low-frequency radars may fail to detect weak echoes. JWRada-32®, using 80GHz millimeter-wave radar, accurately captures weak liquid surface echoes, providing precise, continuous readings even under smooth or low-reflection conditions.

Safety and Protection Requirements

Diesel is flammable and explosive, requiring high safety standards for level measurement devices. JWRada-32® supports Ex ia or Ex d explosion-proof designs, enabling safe operation in hazardous areas while providing remote monitoring and high/low limit alarms to prevent overfill, pump dry-run, or other safety incidents.

3. Selection and Configuration

Project Instrument Selection:

- Model: JWRada-32® Diesel-Specific Version

- Frequency: 80GHz millimeter-wave radar

- Measuring range: 0–60 m (actual tank height ≈3 m)

- Process connection: G1½ threaded (no flange modification required)

- Antenna type: Encapsulated PTFE (resistant to vapor and condensation)

- Protection class: IP67

- Explosion-proof class: Ex db IIC T6 Gb

- Output: 4–20 mA + HART

- Installation: Vertical from tank top, aimed at tank bottom

Reasons for Selecting JWRada-32®:

- Stable low-dielectric liquid detection: Specialized signal algorithms ensure accurate diesel level measurement even with weak echo.

- Zero blind zone design: Short blind zone antenna and proper vertical installation allow almost full monitoring in shallow or restricted tanks.

- Encapsulated antenna: Unaffected by condensation, vapor, or dust, ensuring long-term stability.

- Threaded installation, quick deployment: Standard thread allows plug-and-play installation without modifying the tank.

- Easy commissioning, no shutdown required: No need to open or stop tanks; remote configuration and echo display adjustment accelerate setup.

4. Installation and Commissioning

Site Conditions:

The 3 m deep underground diesel tank is located in a manhole at ground level. The confined space and heavy condensation, combined with temperature differences, present challenges to traditional level instruments. Continuous measurement with high/low limit alarms was required.

Installation Steps:

The installation team removed the old mechanical gauge, cleaned the tank thread, and checked the sealing ring. JWRada-32® was screwed directly into the tank top. Tank height, empty tank, and full tank references were set, and 4–20 mA output was calibrated to the control system. The full installation took ~25 minutes without lifting equipment or hot work.

Commissioning Results:

After installation, echo curves were clear and continuous. Level fluctuation was within ±1 mm, and deviation from actual filling was <0.5%. Steam, condensation, and diesel vapors had no impact. JWRada-32® provided stable, reliable level monitoring in low-dielectric, confined, and high-humidity environments.

5. Application Results and Customer Feedback

- Continuous stable measurement: Operated over 6 months in hot summer and cold winter without drift or interruption.

- Remote monitoring replaced manual inspection: Manual checks every shift were eliminated; data now read in control room with automated high/low alarms, reducing inspection frequency by ~70%.

- Prevented diesel leaks and supply risks: Accurate low-level alarms avoided potential spills and generator downtime.

- Minimal maintenance: No cleaning or adjustment required during the 6-month period.

- Compact space installation feasible: Encapsulated antenna bypassed obstacles inside tank, ensuring accurate readings in tight manholes.

Overall Effect:

The customer highly praised the JWRada-32® as “reliable, maintenance-free, and easy to install.” Plans are in place to add two more underground diesel tanks with the same system, extending centralized remote monitoring and automatic alarm management.

6. Technical Specifications

| Parameter | Value |

|---|---|

| Medium | Diesel |

| Tank Type | 15 m³ Underground Horizontal Tank |

| Range | 0–3.5 m |

| Connection | G1½ Thread |

| Frequency | 80GHz |

| Explosion-proof | Ex db IIC T6 Gb |

| Protection | IP67, IP68 |

| Output | 4–20 mA / HART |

| Temperature | -40 ~ +220°C |

| Pressure | -1 ~ 40 bar (-0.1 ~ 4.0 MPa) |

| Accuracy | ±1 mm |

7. Case Summary and Demonstration Value

This case demonstrates that underground diesel tanks, due to sealed structures, high vapor concentration, condensation, and difficult maintenance, require more stringent liquid level measurement than conventional aboveground tanks.

JWRada-32® Advantages:

- Optimized detection of low-dielectric liquids

- Zero/short blind zone for restricted or shallow tanks

- Plug-and-play threaded installation

- Encapsulated antenna resistant to moisture and condensation

- Long-term maintenance-free operation

- Compatible with 4–20 mA / HART output for remote monitoring and automated alarms

The project significantly improved diesel supply monitoring accuracy, responsiveness, and safety, reducing downtime and leakage risks. This solution can be applied to other underground tank scenarios, such as sewage tanks, LNG buried tanks, and chemical storage tanks, particularly in confined spaces requiring remote monitoring and long-term maintenance-free operation, providing a replicable technical benchmark for the industry.