Application of JWrada®-35 Radar Level Transmitter in Open-Cast Mining Operations

Reliable and verifiable level measurement under harsh operating conditions

Stable and verifiable level measurement under challenging operating conditions

Open-cast mining presents complex operating conditions for level measurement instrumentation. High dust levels, continuous vibration, irregular bulk solids, and long-term exposure to outdoor environments can affect measurement stability. Reliable and verifiable level data are essential for continuous production and process safety. Instrumentation must be capable of maintaining accuracy under these conditions to ensure operational reliability and reduce the risk of equipment or process disturbances.

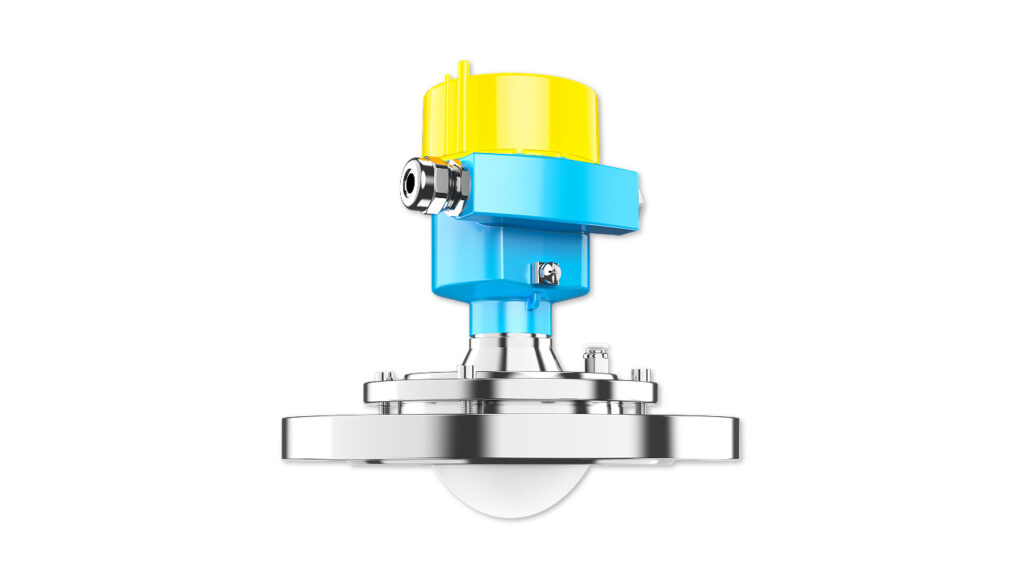

The JWrada®-35 radar level transmitter combines high-frequency radar measurement with a comprehensive software system to address these challenges, providing a robust solution for monitoring material levels in exposed mining environments.

Operating conditions and measurement challenges in open-cast mining

Typical level measurement points in open-cast mining are located at critical process stages such as crusher infeed chutes, buffer silos, and intermediate storage bins. Bulk materials such as melaphyre, basalt, or similar hard rock materials are characterised by large particle size distribution, irregular surfaces, and intense dust generation during feeding and crushing operations. These processes are accompanied by continuous mechanical vibration and material impact.

In addition, outdoor installation exposes level instruments to significant temperature variations, wind, rain, and seasonal weather changes. Measurement systems must therefore not only respond quickly to level changes but also maintain consistent performance over long operating periods. Under such conditions, conventional ultrasonic or contact-based level measurement technologies often struggle with signal instability and increased maintenance requirements.

Engineering advantages of high-frequency radar measurement

To address the complex operating conditions found in open-cast mining, the JWrada®-35 uses 80 GHz high-frequency radar technology for continuous, non-contact level measurement. The high operating frequency enables a narrow beam angle and high spatial resolution, allowing the radar signal to be precisely focused on the actual material surface while minimising interference from vessel walls, structural components, or internal installations.

Unlike acoustic measurement principles, radar measurement does not depend on air or material properties for signal propagation. As a result, high dust concentrations, strong air turbulence, and continuous vibration have little influence on measurement performance. Even during active filling processes with heavy dust clouds, the JWrada®-35 provides stable and repeatable measurement results. Furthermore, radar measurement is inherently insensitive to temperature fluctuations, making it well suited for outdoor installations with large day–night temperature variations.

Software capability as a key factor for long-term measurement reliability

In demanding industrial environments, reliable level measurement depends not only on sensor hardware but also on the ability of the software to interpret radar echoes correctly and adapt to changing process conditions. One of the core strengths of JWrada® radar level transmitters lies in their fully self-developed software platform.

JWrada® radar instruments support a comprehensive range of software functions, including firmware updates, application-specific commissioning, parameter configuration, and detailed diagnostic fault code access. These capabilities allow engineers to continuously optimise measurement performance throughout the instrument’s lifecycle rather than relying solely on initial commissioning settings.

Notably, the JWrada®-35 supports a cloud-based remote commissioning mechanism. Through a secure cloud server, JWrada® engineers can collaborate one-on-one with on-site personnel, remotely accessing real-time device status data while simultaneously viewing radar echo curves and EFT curves. This enables professional signal analysis and targeted optimisation based on actual process conditions.

More importantly, commissioning can be tailored to each specific installation. Parameters and signal-processing algorithms can be adjusted according to the unique material characteristics and vessel geometry, ensuring optimal measurement performance in each individual application. This cloud-based remote debugging architecture is entirely self-developed by JWrada® and currently has no direct equivalent among other domestic radar level transmitter suppliers.

Typical applications in crushing and storage processes

In practical open-cast mining operations, the JWrada®-35 is commonly used for level monitoring at crusher infeed points and buffer silos. These applications place particularly high demands on measurement reliability, as accurate level information is required to prevent overfilling, material blockage, or equipment overload.

By providing continuous, stable, and traceable level signals, the JWrada®-35 enables control systems to regulate material flow effectively and maintain smooth coordination between upstream and downstream processes. Over extended operating periods, stable measurement performance helps reduce unplanned downtime caused by false alarms or signal fluctuations.

Installation and maintenance considerations for harsh environments

Ease of installation and reduced maintenance effort are critical factors in high-risk and hard-to-access mining environments. The JWrada®-35 features a compact mechanical design that supports installation in confined spaces and on silo roofs. Clear parameterisation logic and straightforward commissioning procedures help shorten on-site start-up time.

Thanks to its non-contact measurement principle, the instrument avoids mechanical wear and material buildup, significantly reducing routine maintenance requirements. This is particularly advantageous for open-cast mining operations, where continuous operation and limited access make frequent manual intervention impractical.

Conclusion

Open-cast mining operations require level measurement instrumentation that can maintain accuracy and reliability under high dust, vibration, and environmental variability. Integrating high-frequency radar technology with a software system capable of remote monitoring, parameter optimisation, and diagnostic analysis, the JWrada®-35 radar level transmitter demonstrates a robust approach to consistent, verifiable material level measurement in demanding industrial applications. These capabilities provide data that can be used for operational decision-making, process control, and maintenance planning, without relying on brand-centric or promotional framing.