Bleaching Tower Level Measurement and Point Level Detection Case Study

— Jiwei JWrada® Radar Level Meter and Ring-11 Level Switch for High-Temperature, High-Density Pulp Monitoring

Process Background

The bleaching process is a critical step in pulp and paper production, determining both pulp quality and paper whiteness. Bleaching towers typically reach heights of up to 25 meters and are used for continuous processing of high-fiber pulp. Chemicals such as oxygen, ozone, or hydrogen peroxide are used for bleaching. Pulp temperatures inside the tower can reach 85–95°C, and the process runs continuously without fully emptying the tower.

Pulp density varies between batches, and the tower contains significant amounts of steam and chemical vapors. Traditional contact-type level instruments often face challenges such as build-up, signal drift, and frequent maintenance, which can disrupt production and pose safety risks.

To ensure accurate and reliable level monitoring in the bleaching tower, a large pulp manufacturer in Zhejiang implemented Jiwei Automations’ intelligent level monitoring solution: the JWrada® radar level meter combined with the Ring-11 level switch. This setup enables continuous material level measurement and high/low point detection, ensuring safe and stable operation of the bleaching process.

Measurement Tasks and Process Data

- Measurement Task: Continuous level measurement and extreme point detection

- Measurement Points: Top and middle sections of the bleaching tower

- Measuring Range: 0–25 m

- Medium: Bleached pulp (high-fiber content)

- Process Temperature: +85 – +95 °C

- Process Pressure: Atmospheric (0 bar)

- Special Challenges: Pulp density variation, steam interference, chemical corrosion, condensation inside the tower

Jiwei Solution

JWrada® Radar Level Meter — Non-Contact Continuous Measurement

To address the complex conditions of the bleaching tower, the JWrada® radar level meter employs 80 GHz high-frequency radar technology with a narrow beam angle, achieving precise level tracking across the 25-meter range. The high-frequency radar focuses on the reflected signal, maintaining stable measurement even under variable pulp densities, steam, and foam interference.

Key Advantages:

- Non-Contact Measurement: Radar signals are unaffected by pulp adhesion, reducing the need for manual cleaning inside the tower.

- Strong Anti-Interference Capability: Adaptive signal processing algorithms distinguish valid echoes from reflections and noise, ensuring continuous measurement.

- Maintenance-Friendly: Fully sealed design withstands high-temperature steam and chemical exposure.

- User-Friendly Operation: Real-time monitoring and alarm status are accessible via mobile app, with remote adjustment of alarm thresholds.

- High Accuracy: Level measurement error is limited to a few millimeters, providing stable data for continuous bleaching control.

- Fast Response: Updates level data promptly during changes in pulp feed or discharge rates.

- Historical Data Logging: Records level trends and alarm events for process optimization and maintenance analysis.

- Flexible Installation: Lightweight design and versatile mounting options allow deployment in high towers and constrained spaces.

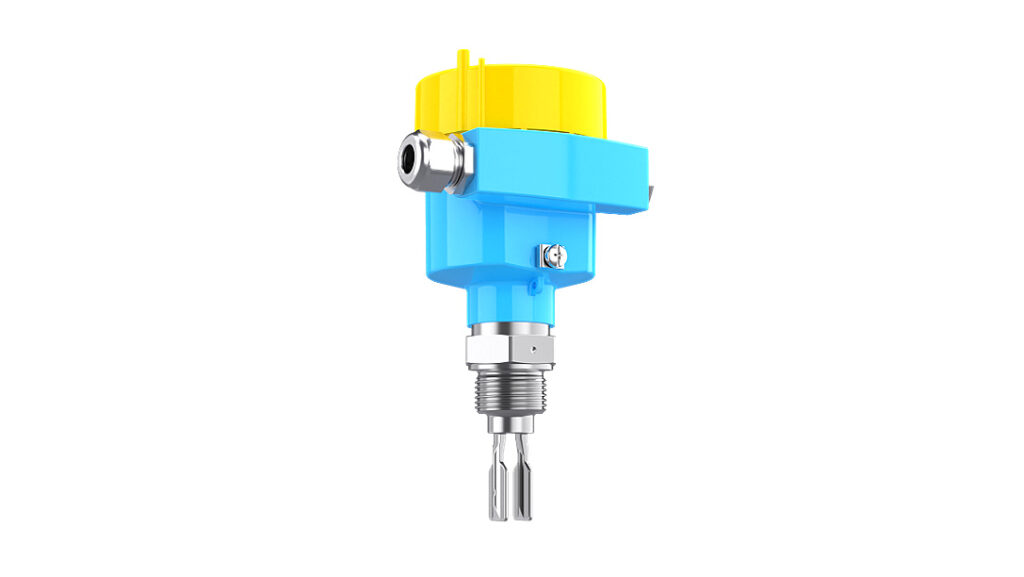

Ring-11 Level Switch — Multi-Function Extreme Point Protection

At the bottom of the bleaching tower, pulp is discharged through a screw conveyor. Ring-11 level switches are installed at key locations to prevent overfill or empty-tank conditions. Ring-11 offers four output modes (DPDT, SPST, NAMUR, PNP) and carries multiple certifications (SIL, EAC), ensuring reliable alarms under high temperature, corrosive, and challenging environments.

Key Advantages:

- Multiple Output Modes: DPDT, SPST, NAMUR, and PNP outputs allow integration with DCS, PLC, and safety systems.

- High Reliability: Robust structure withstands steam, vibration, and corrosive conditions in continuous operation.

- Chemical Resistance: Stainless steel fork probe tolerates high-temperature bleached pulp and bleaching chemicals, ensuring long-term stable operation.

- Precision and Responsiveness: Sensitive to high/low level changes, providing rapid extreme point alarms to ensure safety.

- Anti-Adhesion Design: Fork structure minimizes interference from pulp build-up, preventing false triggers.

- Maintenance-Free: No frequent calibration or adjustments required; quick and easy installation.

- Easy Operation: Mobile app allows real-time monitoring of high/low level status, reducing manual inspection.

- Process Flexibility: Probe length and installation position can be adjusted according to tower design and process requirements.

Application Results

After six months of operation, the bleaching tower level monitoring system has proven stable and reliable. The JWrada® radar level meter provides continuous level measurement, while Ring-11 switches offer high/low point alarms, ensuring smooth bleaching operations without signal-related shutdowns.

Field instrumentation engineer Zhao commented:

“Previously, level instruments inside the tower required frequent cleaning due to steam and pulp adhesion. Now, almost no manual intervention is needed. Using the mobile app, we can monitor level curves and alarm status in real time, which is very intuitive and reduces inspection work.”

The combination of non-contact radar measurement and maintenance-free Ring-11 level switches has significantly reduced maintenance costs while enhancing production safety and operational convenience.

User Benefits

The JWrada® radar level meter continuously tracks pulp levels under high temperature, steam, and variable density conditions, while Ring-11 provides reliable high/low extreme point protection, preventing overfill or empty-tank scenarios. Non-contact measurement and maintenance-free design greatly reduce manual inspections and tower cleaning. Operators can monitor level trends and alarm status in real time via mobile app, improving operational efficiency. The four output modes of Ring-11 ensure compatibility with DCS, PLC, and safety systems, making the system reliable, intuitive, and a stable solution for bleaching tower level monitoring.

Conclusion

The successful implementation of the bleaching tower level monitoring project has strengthened the manufacturer’s confidence in domestic instrumentation and validated the reliability and maintainability of the JWrada® radar level meter and Ring-11 level switch combination under high-temperature, high-density pulp conditions.

Project manager Jiang noted:

“As domestic chemical and pulp industries demand more continuous monitoring and automation, breakthroughs in local instrumentation design and algorithms are highly significant. They not only replace imported equipment but also help build an independent technology system.”

This case provides a reference for bleaching towers and similar high-temperature, challenging process environments, supporting digital transformation and smart manufacturing upgrades in the industry.