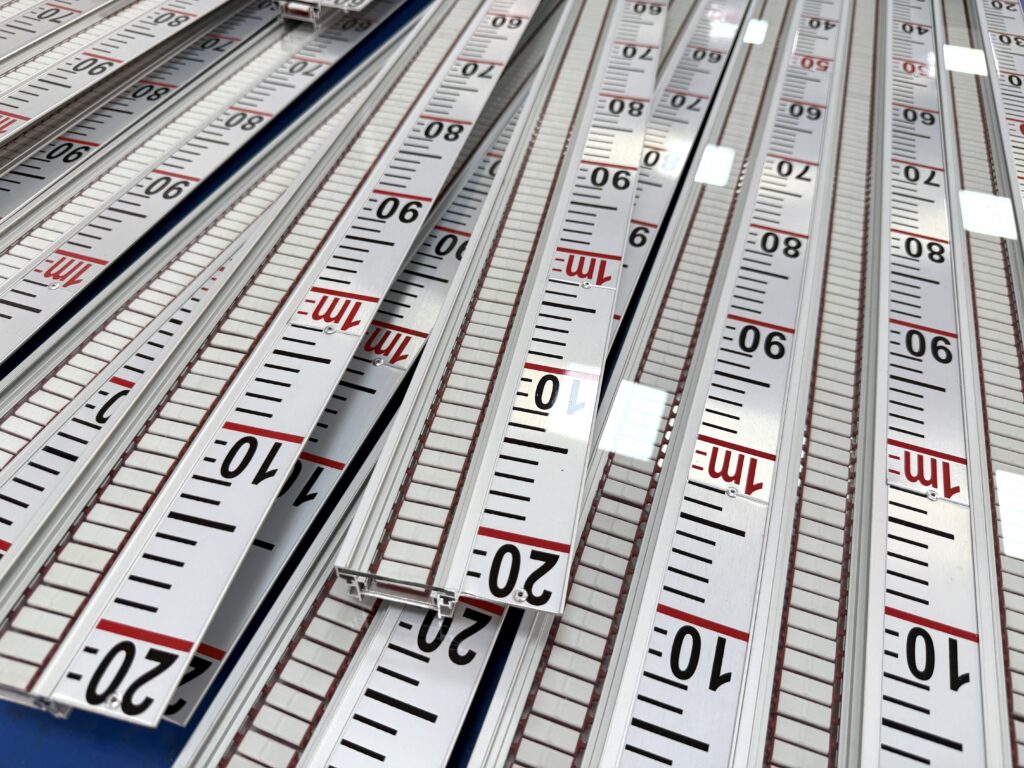

Degreasing Process and Its Role for Magnetic Level Gauges

Background

In the energy, chemical, and petrochemical industries, certain pipelines, fittings, and measurement instruments are designed to come into direct contact with oxygen or other reactive media. Any residual grease on these components can pose severe safety hazards. Therefore, conducting a rigorous degreasing process for magnetic level gauges and related measurement instruments is crucial for ensuring operational safety and product quality.

Shenzhen Jiwei Automations Ltd. strictly adheres to degreasing standards during the production of magnetic level gauges, ensuring that all grease and organic residues are completely removed before the products leave the factory. This guarantees safe and reliable measurement equipment for energy, chemical, and related industries.

1. Definition and Purpose of Degreasing

Degreasing, also known as oil removal, refers to the process of eliminating grease and organic contaminants from the surface of pipelines, fittings, or instruments. In processes involving oxygen or reactive media, degreasing is essential. Its main objectives include:

- Preventing reactions between oxygen and residual grease

Residual grease can easily ignite or explode in high-pressure oxygen environments. Degreasing eliminates this potential risk, ensuring safe operation of pipelines and instruments. - Preventing explosive reactions with materials

In pipelines transporting flammable or explosive substances, residual grease may trigger chemical reactions, leading to fire or explosion. Degreasing removes these hazards. - Ensuring material purity

Contamination of chemical raw materials, gases, or liquids with grease can affect product quality and process accuracy. Degreasing ensures material purity and process stability. - Controlling grease and organic content

Standardized degreasing processes limit residual grease and organic matter within design specifications, ensuring compliance with process requirements and safety standards.

2. Degreasing Methods and Procedures

Common industrial degreasing methods include:

- Internal pipeline immersion

Organic solvents are injected into the pipeline and allowed to soak, effectively dissolving and removing grease. Suitable for small to medium diameter pipelines and instrument bodies. - External surface wiping for large pipelines

Large diameter pipelines or instruments are wiped with brushes or cloths soaked in degreasing agents to remove grease from external surfaces. - System circulation degreasing

The entire pipeline system is circulated with degreasing solutions, suitable for complex piping networks and large chemical equipment.

Common Degreasing Agents:

- Organic solvents: Dichloroethane, trichloroethylene, carbon tetrachloride, industrial alcohol, etc. Organic solvents must contain ≤50 mg/L of oil.

- Acidic or alkaline solutions: Nitric acid ≥65%, alkaline degreasing liquids. Suitable for removing highly adherent grease.

Selection of degreasing agents must consider pipeline material, conveyed medium, and safety standards to ensure thorough cleaning without damaging the equipment.

3. Degreasing Process for Magnetic Level Gauges

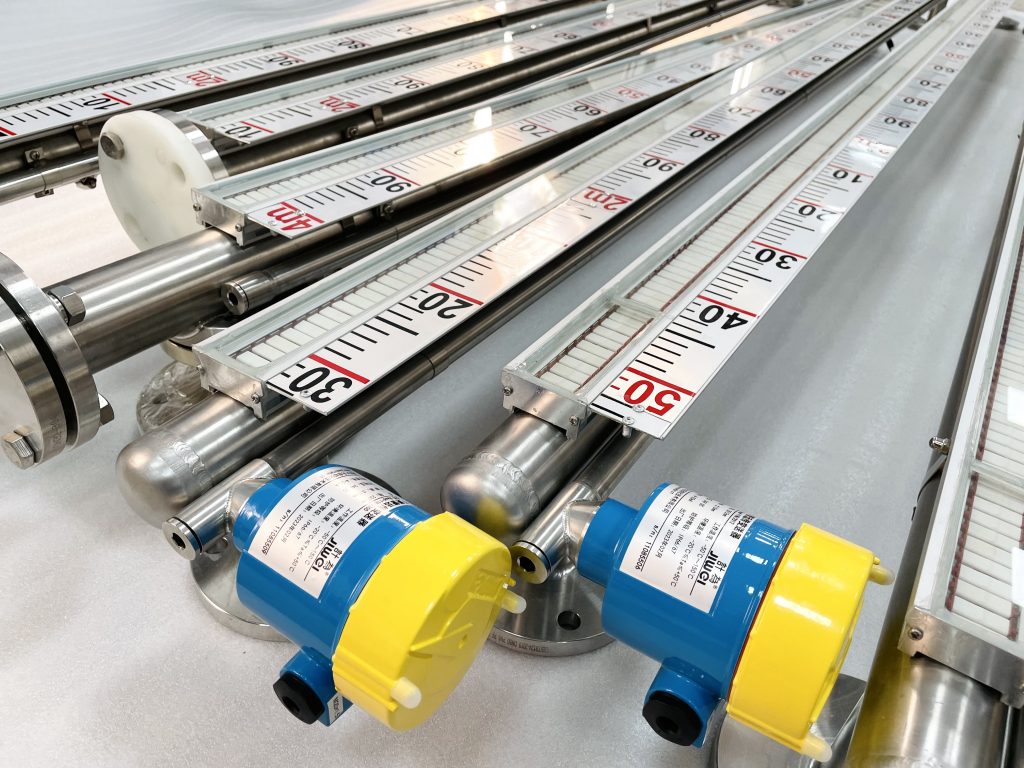

Magnetic level gauges are widely used in the energy and chemical industries, particularly in oxygen, nitrogen, or other gas environments, where rigorous degreasing is critical. Shenzhen Jiwei Automations Ltd. implements the following degreasing steps:

- Injection Degreasing

Organic solvent is injected into the instrument body at approximately 0.6–0.7 L per meter of tube, ensuring full contact with the internal wall to dissolve grease. - Immersion Degreasing

The instrument tube is placed horizontally in a degreasing tank for 1–1.5 hours. The tube is rotated every 15 minutes to ensure uniform cleaning of the internal surface. - Wiping Degreasing

A cloth bound with galvanized wire, soaked in degreasing solution, is used to scrub the internal tube repeatedly. The cloth is replaced with a clean one multiple times to ensure complete removal of grease.

After degreasing, residual liquid is drained promptly. The tube is first rinsed with oil-free clean water, then dried with purified air or naturally. Finally, the tube openings are sealed with anti-rust plastic sheets to prevent secondary contamination.

4. Quality Assurance After Degreasing

After degreasing, the magnetic level gauge and associated components must meet the following standards:

- No residual grease: Completely clean internal and external surfaces

- Corrosion protection: Surface remains intact without chemical damage

- Process compliance: Safe for contact with oxygen or reactive media

- Packaging protection: Openings sealed to prevent contamination during transport and storage

Standardized degreasing ensures long-term measurement accuracy and operational safety of magnetic level gauges, reducing process-related risks.

5. Significance of Degreasing in Industry

In the energy, chemical, petrochemical, and oxygen-related production sectors, degreasing is not just a technical step but a vital safety measure. Its key benefits include:

- Ensuring operational safety: Prevents fire or explosion due to residual grease

- Improving instrument reliability: Ensures stable, long-term operation of magnetic level gauges

- Optimizing process accuracy: Maintains material purity and prevents product contamination

- Reducing maintenance costs: Minimizes on-site cleaning and maintenance frequency, increasing equipment availability

- Meeting standards: Complies with domestic and international safety and quality certifications

For high-risk industries, degreasing is an indispensable step for pre-delivery quality assurance.

6. Shenzhen Jiwei Automations Ltd. Practices

Shenzhen Jiwei Automations Ltd. rigorously enforces degreasing standards in the production of magnetic level gauges:

- All products requiring degreasing undergo strict process treatment

- Injection, immersion, and wiping methods are applied to ensure complete grease removal

- Drying and sealing prevent secondary contamination

- Degreasing agent types and oil content are strictly controlled to meet industry standards

- R&D center regularly audits and optimizes the degreasing process to ensure long-term safety and reliability

Through scientific and standardized degreasing, Jiwei magnetic level gauges demonstrate excellent safety and reliability in energy, chemical, and oxygen-contact processes, providing high-quality, low-risk measurement solutions.

7. Conclusion

The degreasing process of magnetic level gauges and other measurement instruments is irreplaceable in the energy, chemical, and oxygen-contact industries. Proper degreasing not only ensures safety but also enhances device reliability, maintains material purity, reduces maintenance costs, and complies with process and safety standards.

Shenzhen Jiwei Automations Ltd. adheres to the principle of “Safety, Standardization, Reliability”, implementing rigorous degreasing processes in magnetic level gauge production to provide high-quality, long-term stable instruments for domestic and international energy and chemical enterprises.