Comprehensive Guide to Level Transmitter Selection: Principles, Parameters, and Industry Applications

Importance of Level Transmitter Selection in Industrial Automation

Level transmitters are critical measurement instruments in industrial automation. Proper selection directly affects production safety, process control, maintenance costs, and system stability. Across chemical, food, pharmaceutical, energy, and environmental industries, an appropriate level measurement solution ensures continuous operation and equipment safety. This article systematically analyzes level transmitter selection, providing engineers with professional guidance from process analysis to installation and maintenance.

1. Basic Selection Process

- Define measurement target and process conditions

Consider liquid type, medium state (liquid/slurry/mud), temperature, pressure, corrosiveness, viscosity, flowability, presence of gas or foam. - Determine measurement type

- Point level: High/low alarms, overflow prevention, pump dry-run protection.

- Continuous level: Process adjustment, inventory management, data analysis.

- Select measurement principle

Common principles: mechanical, magnetic float, vibrating fork, capacitance, radar, ultrasonic, guided wave radar. Each has advantages and limitations depending on conditions. - Confirm process constraints

Installation space, flange standards, temperature and pressure range, fluid impact, stirring, electromagnetic interference, and corrosive environment. - Consider maintenance and cost

Ease of onsite calibration, maintenance cycle cost, remote adjustment, and upgrade capability. - Verify with field test

Prototype or onsite testing ensures long-term reliability.

2. Common Measurement Principles and Selection Reference

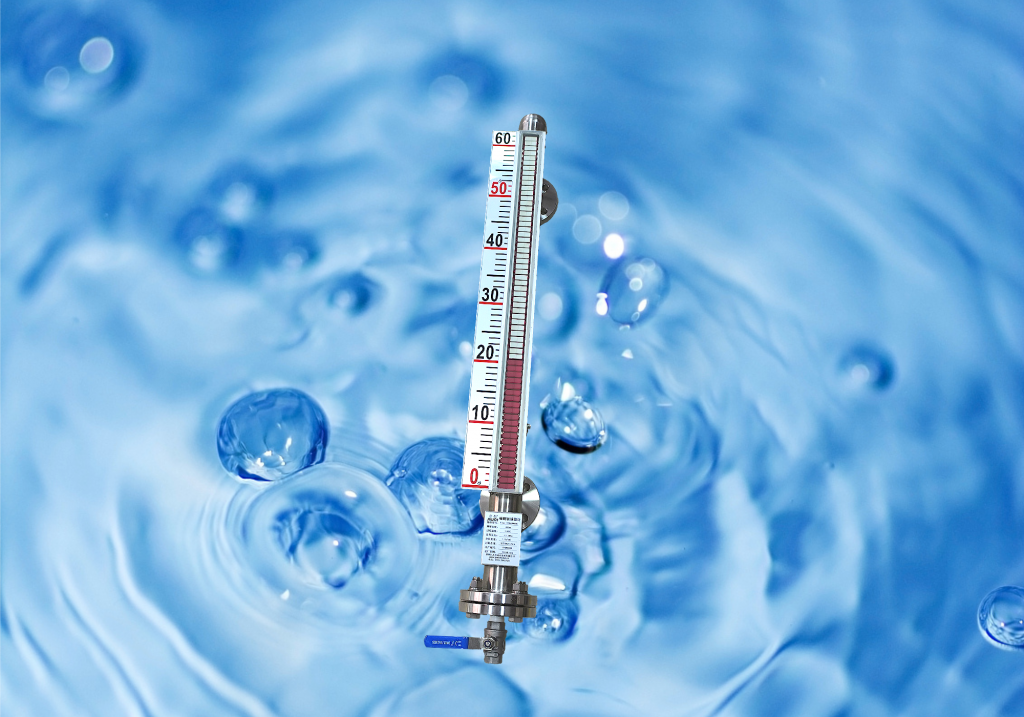

1. Magnetic Level Gauge

Principle: Float moves with liquid, flips internal magnetic plates to indicate level; outputs switch or analog signal.

Advantages: Visual indication, optional high/low alarms, simple reliable structure, mechanical type needs no external power, suitable for mildly corrosive liquids.

Limitations: High viscosity, crystallization, or suspended solids may affect float; high pressure/temperature needs reinforced design.

Application: Clean liquids, low to moderately corrosive media.

2. Float Level Meter

Principle: Float moves with liquid, activates reed or mechanical switch for high/low alarms.

Advantages: Simple, flexible, cost-effective; reliable point level detection; easy maintenance.

Limitations: High viscosity, fouling, or solids may affect operation; only suitable for point alarms.

Application: Clean, low-viscosity, low-corrosion liquids.

3. Vibrating Fork (Tuning Fork) Level Switch

Principle: Detects frequency change when fork is covered by liquid, triggers high/low alarms.

Advantages: Insensitive to density or conductivity, strong anti-fouling, almost maintenance-free.

Application: Viscous, particulate, corrosive media for critical safety points.

4. Capacitance Level Switch/Transmitter

Principle: Measures liquid level via dielectric constant change.

Advantages: Point or continuous measurement, compact, easy installation.

Limitations: Large dielectric variation may cause false alarms; suspended solids affect accuracy.

Application: Clean or stable media.

5. Ultrasonic Level Meter

Principle: Measures liquid level via emitted and received ultrasonic pulses.

Advantages: Non-contact, suitable for corrosive or fouling media; remote reading.

Limitations: Foam, vapor, bubbles, and high temperature may reduce accuracy.

Application: Wastewater, corrosive liquids, slurries.

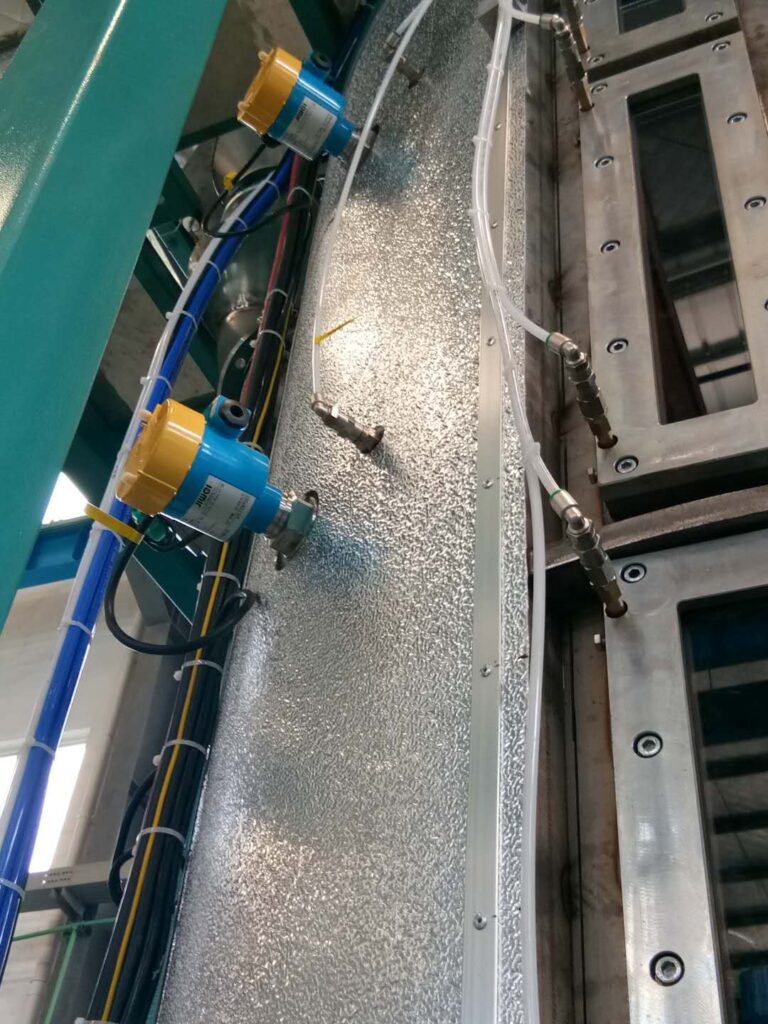

6. Radar Level Meter (Microwave/Guided Wave)

Principle: High-frequency microwave pulse reflection measures liquid level.

Advantages: Non-contact or guided wave, foam and vapor resistant, high temperature and pressure, long-term stability.

Limitations: Higher cost; low dielectric media may reduce accuracy.

Application: Chemical, high temp/pressure, corrosive, or particle-laden continuous measurement.

3. Key Selection Parameters

- Range and installation height: Ensure maximum/minimum levels within transmitter range; consider tank type, space, beam angle.

- Process connection: Flange, thread, or clamp; high pressure/low temperature requires reinforced flange.

- Medium compatibility: Corrosive liquids require stainless steel, Hastelloy, or PTFE lining; slurry needs anti-fouling design.

- Temperature and pressure: Continuous transmitters must support process conditions; extreme environments may need cooling or signal isolation.

- Signal output: Point: relay, dry contact, PNP/NPN; Continuous: 4–20 mA, HART, Modbus, Profibus.

- Maintenance and expandability: Cleaning difficulty, remote tuning, firmware upgradeability, life-cycle costs.

4. Installation Considerations

- Avoid dead zones/interference: Floats away from walls/agitators; radar/ultrasonic away from beams, pipes, steam.

- Combine point and continuous measurement: Point for safety, continuous for process control.

- Signal integration: Compatible with PLC/DCS for timely control/alarm.

- Reserve maintenance space: Frequent cleaning or adjustment needs sufficient access.

5. Typical Industry Applications

- Chemical: Acid/base/solvent tanks, radar+vibrating fork combo.

- Food: Milk, sauces, slurry; stainless vibrating fork or guided radar.

- Water treatment: Sedimentation or regulation tanks; radar widely used.

- Energy & Environment: Biogas slurry, mud, oil-water separation; vibrating fork + radar.

- Petrochemical: Oil tanks with high-pressure/high-temperature; radar + fork.

6. Summary and Strategy

Level transmitter selection is a comprehensive decision: process analysis + principle matching + installation optimization + long-term maintenance.

Core principles:

- Safety first: reliable alarms at critical points to prevent overflow or pump dry-run.

- Stability: insensitive to medium variations, minimal maintenance.

- Strong adaptability: meet temp, pressure, corrosiveness, viscosity, and process disturbances.

- Economy and maintenance: reduce installation/commissioning difficulty, remote upgrade preferred.

- Field validation: prototype or site test for complex conditions.

Scientific selection ensures accurate level data, enhances production safety, optimizes processes, reduces maintenance costs, and makes level measurement a core instrument for industrial automation and smart factories.