Application Case of Jiwei Dual-Rod Level Switch in Coffee Bean Processing, Baoshan, Yunnan

Yunnan is China’s most important Arabica coffee-producing region. Among its sub-regions, Lujiangba in Baoshan is recognized within the industry as one of the core areas producing the highest-quality coffee beans, thanks to its unique altitude, soil, and microclimate. Lujiangba hosts multiple mature coffee bean processing facilities covering the complete production chain, including green bean procurement, cleaning, hulling, roasting, grinding, and packaging.

Coffee bean processing involves multiple stages, each with distinct material characteristics, often featuring high dust levels, low density, and easily suspended particles. These characteristics pose significant challenges for level measurement. Traditionally, many factories relied on low-cost mechanical switches, which frequently caused material shortages, hopper blockages, and false alarms, directly affecting production continuity and coffee quality.

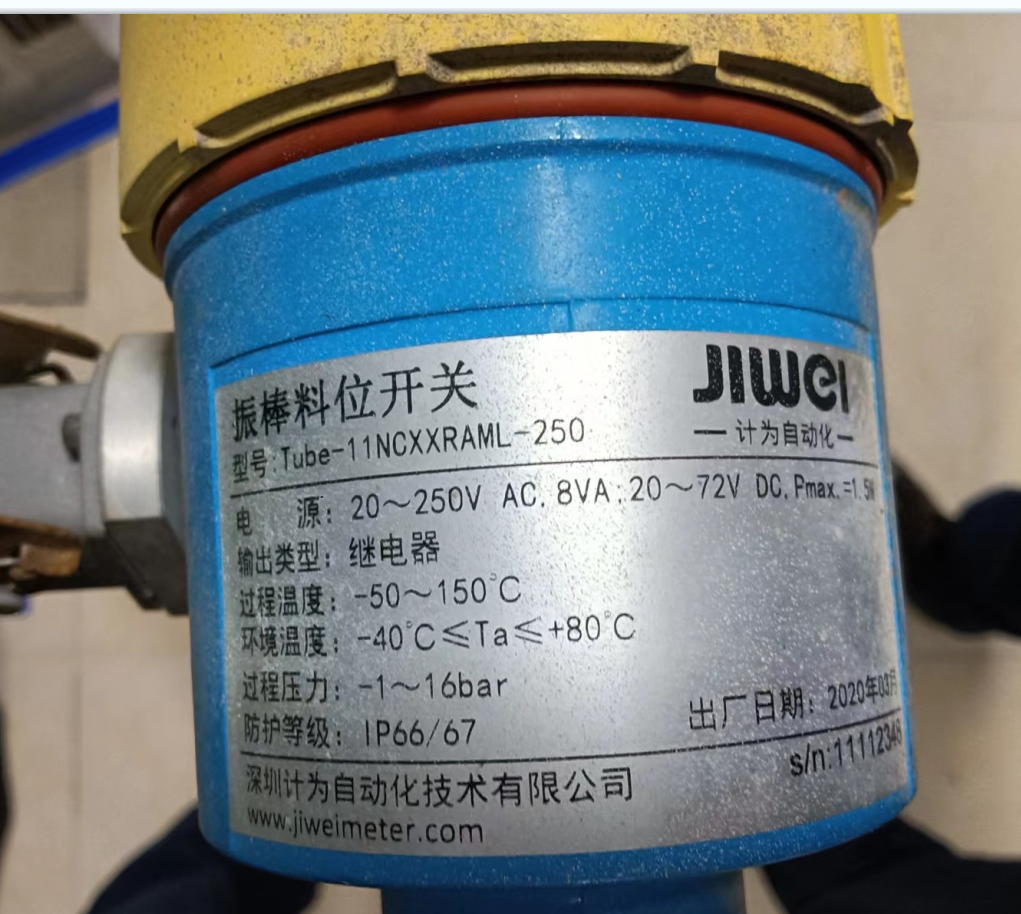

To address these issues, the factory introduced the Jiwei dual-rod level switch, independently developed by Shenzhen Jiwei Automation Technology Co., Ltd. The dual-rod design provides significantly higher reliability compared to single-rod solutions and is protected by multiple national invention patents (201610511184.7, 201510009538.3, 201510059187.7, 201520009337.9, 201520012324.7, 201520215527.6, 201520332293.3, 201620679133.0, ZL 201920496471.4, ZL201921754721.6). Its performance can rival international brands such as VEGA and even outperform them in certain complex operating conditions. This case study details the application and engineering experience of Jiwei dual-rod level switches in green bean hoppers (feeding the Destoner and Huller), roaster feeder hoppers, and ground coffee intermediate hoppers.

I. Project Background and Process Characteristics

The modern coffee market demands a variety of product forms. Consequently, factories typically produce three types of products simultaneously:

- Green Beans — supplied to roasting shops or enthusiasts; continuous feeding to the green bean hopper is essential.

- Roasted Beans — fully roasted beans ready for brewing; precise level control in the roaster feeder hopper is critical.

- Ground Coffee — ground beans for cafés or home users; the intermediate hopper feeding the grinder must ensure continuous supply and minimize dust issues.

Thus, different process stages require distinct equipment to monitor material levels effectively, including the green bean hopper, roaster feeder hopper, and grinder intermediate hopper.

The factory processes approximately 20–25 tons of green beans per day. The production line includes cleaning, density sorting, hulling, roasting, grinding, and packaging. During processing, the physical characteristics of coffee beans change significantly:

- Green Bean Stage: Density is relatively high (≈0.65–0.7 g/cm³), particles are large and flow well, but uneven piling can form “slopes,” challenging traditional mechanical switches.

- Roasting Stage: Beans lose 40–60% density after high-temperature roasting; vibration can cause level misreading.

- Grinding Stage: Ground coffee powder is low-density (0.25–0.35 g/cm³), easily suspended, and adhesive, generating significant dust that complicates level monitoring.

Reliable level switches are essential for continuous feeding, ensuring each stage operates smoothly while maintaining consistent coffee quality.

Before installing Jiwei dual-rod switches, the production line experienced:

- False alarms in the roaster hopper, requiring manual intervention;

- Inaccurate green bean hopper readings, causing Destoner and Huller interruptions;

- Powder adhesion in the grinder hopper, causing blockages and increasing maintenance frequency.

To solve these issues, the customer fully replaced existing switches with Jiwei Tube-11 dual-rod level switches, improving monitoring reliability and production continuity.

II. Equipment and Installation Locations

This project installed multiple Jiwei dual-rod level switches (standard and extended versions) at three critical workstations: green bean hopper, roaster feeder hopper, and grinder intermediate hopper.

1. Green Bean Hopper

In the green bean hopper, Jiwei dual-rod level switches were installed at the low wall point for empty detection and at the top high point for full detection. Their primary function is to ensure continuous and uniform feeding to the Destoner and Huller, preventing material shortages and hopper overfilling, and maintaining smooth upstream transport.

The green bean hopper presented challenging conditions: unstable pile angles forming local slopes, and significant vibrations. Traditional mechanical switches often generated false alarms, interrupting the Destoner or Huller and impacting production continuity.

Jiwei Solution: The dual-rod design provides a stable detection surface, greatly enhancing anti-vibration performance and reducing false alarms. Adjustable sensitivity adapts to the density of green beans, ensuring accurate detection even in low-density regions. High-frequency vibration ensures readings are unaffected by local pile slopes, guaranteeing continuous feeding to downstream equipment. As a high-end domestic switch, the product is backed by multiple patents and can rival international brands like VEGA in complex conditions.

Customer Feedback: Post-installation, hopper level detection is stable and reliable; continuous feeding to the Destoner and Huller is ensured, reducing material shortages and blockages, lowering operator workload, and improving overall production efficiency.

2. Roaster Feeder Hopper

Jiwei dual-rod switches were installed at the high-level point of the roaster feeder hopper to prevent overfilling, which could destabilize airflow, and to ensure automatic feeding follows the preset roasting curve.

Challenges: High temperature (50–60°C near exhaust pipes), fine lightweight dust prone to adhering to rods, and traditional mechanical switches frequently jamming or producing false alarms.

Jiwei Solution: The dual-rod switches are high-temperature resistant (up to 400°C), well above site requirements. The dual-rod structure and precision tuning reduce material adhesion and maintenance frequency. High-frequency vibration prevents false-full alarms.

Customer Feedback: Feeding is more uniform, roasting curves remain stable, manual intervention is reduced, and overall process reliability is greatly improved.

3. Grinder Intermediate Hopper

Installed at the low point to ensure continuous grinder feeding, and at high points to prevent powder blockages.

Challenges: Low-density powder (0.25–0.35 g/cm³), easily suspended and adhesive, limited hopper space, complex internal structure; traditional switches difficult to install and prone to false readings.

Jiwei Solution: Adjustable amplitude accommodates low-density powders. The dual-rod design ensures reliable detection. Short rod versions enable installation in tight spaces. High-frequency vibration prevents powder adhesion from causing false readings.

Customer Feedback: Feeding is stable, blockages are minimized, overall line flow is smoother, and operator workload is reduced.

III. Application Results

After extended operation, the Jiwei dual-rod switches demonstrated stable and reliable performance:

- Accurate level alarms: False and missed alarms reduced; automated interlocks reliable.

- Dust resistance: Minimal impact from dust, reducing cleaning frequency.

- Anti-vibration: Vibration from roasters or conveyors does not trigger false alarms.

- Continuous production: Accurate signals from all hoppers ensure smooth line operation and lower operator effort.

The dual-rod design outperforms single-rod solutions in reliability. Combined with multiple patents, Jiwei switches handle light, dusty, and high-vibration materials on par with top international brands, sometimes performing even better in complex scenarios.

IV. Why Baoshan Lujiangba is a Typical Case

Lujiangba, Baoshan, Yunnan, is a highland area ideal for Arabica coffee. Beans here are uniform, aromatic, and well-balanced in acidity—representing China’s premium coffee. Local processing plants are numerous, with mature processes covering green bean acquisition, cleaning, hulling, roasting, grinding, and packaging.

Industry-representative conditions: High dust, large density variation from green beans to roasted beans to ground coffee (0.65 → 0.25–0.35 g/cm³), frequent material flow, and strong equipment vibration. These factors challenge level switch performance; mechanical switches often fail, causing blockages or interruptions.

Lujiangba processing plants have tight production schedules and strict equipment stability requirements. Reliable monitoring at green bean hoppers, roaster feeders, and grinder intermediate hoppers is essential to prevent line stoppages. The successful deployment of Jiwei dual-rod switches demonstrates their reliability under these demanding conditions and serves as a reference solution for similar coffee processing facilities.

V. Conclusion

The application of Jiwei dual-rod level switches in Baoshan Lujiangba coffee processing demonstrates their high reliability in handling light, dusty, and high-vibration materials.

- Green Bean Hopper: Ensures continuous feeding to the Destoner and Huller, preventing shortages and local pile issues.

- Roaster Feeder Hopper: High-temperature tolerance and high-frequency vibration prevent false alarms and maintain consistent roasting curves.

- Grinder Intermediate Hopper: Adapted for low-density powders, ensuring continuous feeding and uniform grind size.

This case highlights the reliability and anti-interference performance of Jiwei dual-rod level switches, showcasing domestic high-end level switch R&D capabilities. With multiple national patents, their performance can rival international products like VEGA, and in some complex conditions, surpass them.

The project provides a stable, reliable level monitoring solution, improving production continuity, process stability, and final product quality, and serves as a mature reference for other coffee bean processing facilities with similar requirements.