Why Is 80GHz Radar Replacing 26GHz Products?

Technical Advantages of 80GHz Radar Level Measurement

Level measurement is a critical part of industrial process control, directly affecting equipment safety, production efficiency, and process quality. As industrial environments become increasingly complex—especially in chemical, energy, mining, and LNG/LPG storage sectors—level measurement instruments face multiple challenges including heavy dust, saturated steam, and corrosive media.

Traditional 26GHz radar level meters have played an important role but now reveal technical limitations. In contrast, 80GHz radar level meters, with higher operating frequencies and innovative technologies, have rapidly emerged as the preferred upgrade solution in the industry.

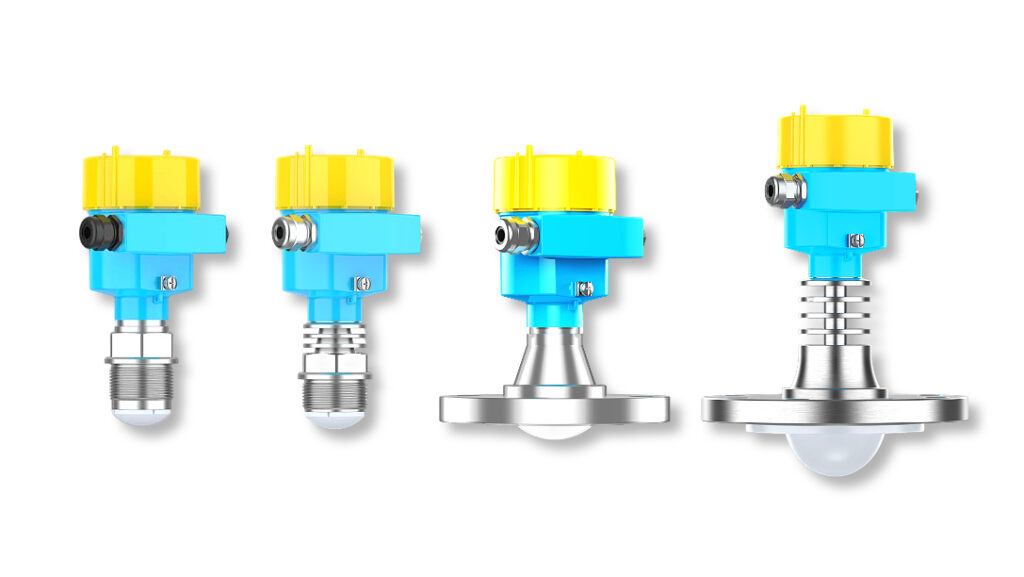

JWrada® 80GHz Radar Level Meter

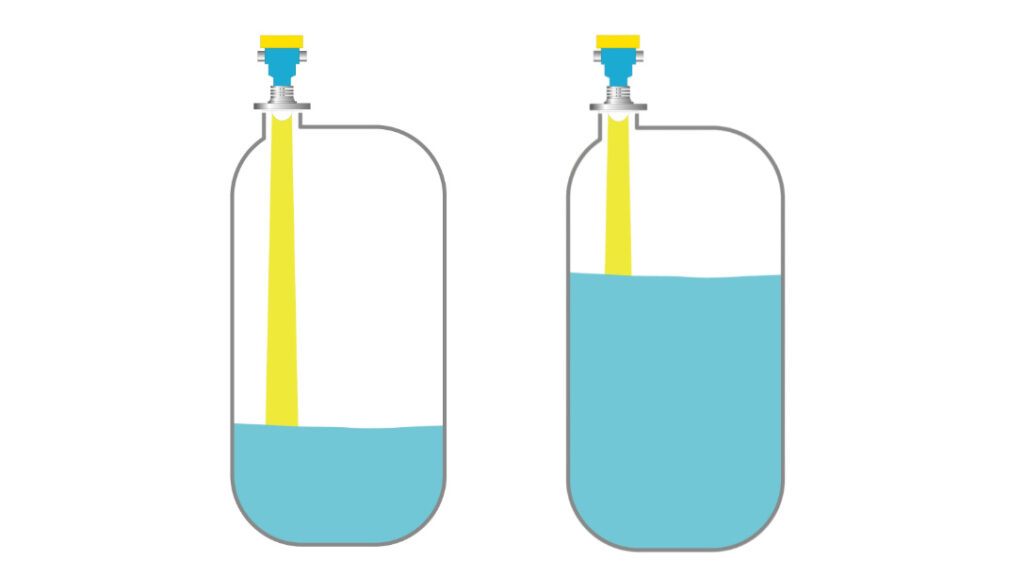

The 80GHz radar operates at a higher frequency and shorter wavelength, offering significant physical advantages. Its beam angle typically ranges between 2° and 4°, allowing more precise focusing on measurement targets. Compared to the wider 8° to 12° beam of 26GHz radars, this narrow beam greatly reduces interference from tank walls and internal structures, improving signal-to-noise ratio and measurement accuracy.

Furthermore, 80GHz radar achieves millimeter-level spatial resolution, with theoretical measurement accuracy reaching ±1mm. This precision is essential for high-accuracy level control. The blind zone is significantly reduced to 50-80mm, addressing the large blind spot issue of 26GHz radars in small tanks and near-field measurements, thus expanding the scope of applications.

Innovative Antenna Design and Material Advantages

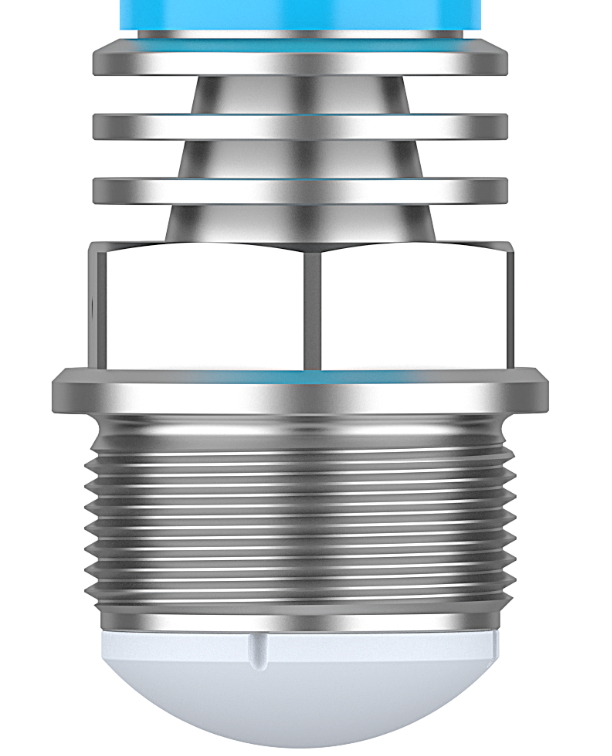

JWrada® 80GHz radar level meters feature high-performance spherical lens antenna designs, enhancing antenna gain and directivity to concentrate electromagnetic waves and improve penetration. Optimizing lens materials and structures achieves stable beam focusing, reduces beam distortion, and increases long-distance signal transmission efficiency and measurement sensitivity.

Some models also utilize parabolic and Cassegrain dual-reflector systems to further boost antenna gain and sensitivity. The antenna housing is fully encapsulated with high-transmission, corrosion-resistant PTFE material and rated IP68, ensuring long-term stability in harsh acidic, alkaline, and salt fog environments.

This high-quality antenna design guarantees measurement accuracy and stability while extending instrument lifespan.

Intelligent Signal Processing Ensures Measurement Reliability

The 80GHz radar level meter is equipped with multi-dimensional echo analysis and dynamic filtering algorithms. These algorithms can identify and eliminate false echoes caused by dust, steam, and agitation in real time, ensuring data purity and accuracy.

Intelligent compensation technology adapts automatically to changes in dielectric constants and temperature fluctuations for more stable measurements. Doppler frequency shift detection captures rapid level changes, meeting dynamic process control needs.

The device supports HART, Modbus, and 4-20mA communication protocols, facilitating remote parameter configuration and health monitoring, significantly reducing maintenance costs and improving system reliability and efficiency.

Application Advantages and Industry Adaptability

80GHz radar level meters perform exceptionally well in dusty silos, cement plants, and ore storage systems. Their narrow beam and high energy concentration enable electromagnetic waves to penetrate dust layers effectively and avoid wall reflection interference, ensuring measurement stability.

In steam-rich heated tanks, reactors, and LNG vaporizers, intelligent steam interference compensation algorithms ensure continuous and accurate measurement, preventing errors from steam refraction and multipath echoes.

For highly corrosive acid, alkali, and salt fog environments, PTFE fully enclosed antennas and aerospace-grade aluminum housings provide strong protection, extending instrument life and ensuring long-term stable operation.

The small blind zone and millimeter-level accuracy also make 80GHz radars ideal for small tanks and confined spaces, meeting the stringent accuracy requirements of pharmaceutical and chemical industries.

Typical Success Case

A coastal chemical plant previously used 26GHz radar level meters, which frequently failed during hot, humid summer conditions, causing signal loss and false echoes that severely disrupted LNG storage operations.

After upgrading to JWrada® 80GHz radar level meters, the Jiwei team optimized beam direction, activated steam interference compensation algorithms, and installed protective covers to mitigate salt fog corrosion.

This upgrade enabled over 12 months of zero-failure operation, improved measurement stability by 98%, and cut maintenance costs nearly in half, greatly enhancing safety and operational efficiency.

Conclusion

With narrow beam angles, high resolution, and ultra-small blind zones enabled by high-frequency operation, combined with advanced antenna design and intelligent signal processing, 80GHz radar level meters overcome the limitations of traditional 26GHz radars in complex industrial environments.

Their excellent anti-interference capability, environmental adaptability, and remote maintenance features make them the preferred solution for modern industrial automation level measurement upgrades.

As intelligent manufacturing and Industry 4.0 evolve, 80GHz radar technology is set to lead level measurement toward greater precision and intelligence.