Pneumatic Conveying System: The Role of Pressure in Efficient Material Transport

In modern industrial plants, handling powders and granular materials is both frequent and critical. In addition to common mechanical systems such as belt and screw conveyors, there is a more “lightweight” solution—pneumatic conveying. It relies on compressed air as the driving force, allowing materials to “travel” through pipelines with efficiency and safety. To keep this “air express network” running smoothly, pressure control plays a decisive role. This article provides an intuitive overview of the working principles, pressure characteristics, and optimization strategies of pneumatic conveying systems.

1. Basic Principles of Pneumatic Conveying

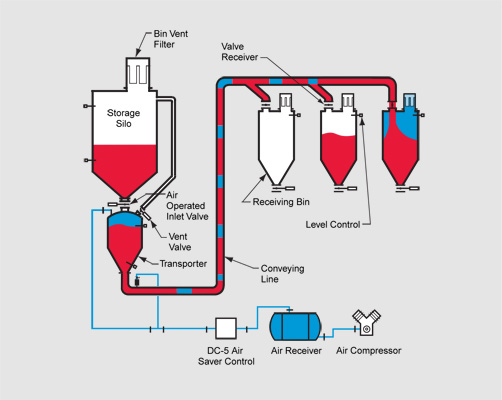

Pneumatic conveying is a technology that uses airflow to move powdered or granular materials through enclosed pipelines. Depending on the conveying mode, systems can be divided into positive-pressure, negative-pressure, and combined types.

- In a positive-pressure system, compressed air pushes materials forward.

- In a negative-pressure system, suction from the downstream end “pulls” materials through the pipeline.

- Combined systems integrate both principles to suit complex conditions and long-distance transport needs.

From the perspective of flow state, pneumatic conveying operates in either dilute phase or dense phase. In a dilute-phase system, air velocity is high and material concentration is low, with particles suspended in the air stream. In contrast, dense-phase conveying features a higher material ratio and lower velocity, with materials moving intermittently in slugs or plugs. Each method differs significantly in energy consumption, wear, and system requirements—the choice depends on material properties and process demands.

2. The Role of Pressure in the System

Pressure in a pneumatic conveying system serves as both the driving force and the control lever. Adequate pressure overcomes pipeline resistance and material weight, ensuring stable flow; excessive pressure, however, increases energy consumption, mechanical stress, and safety risks. Hence, appropriate pressure not only determines conveying efficiency but also affects energy performance and equipment lifespan.

Typically, operating pressure ranges from 0.1 to 0.6 MPa, depending on factors such as conveying distance, material density, and pipeline layout. Heavier materials or longer distances require higher air pressure, while lighter materials and shorter pipelines benefit from lower pressure to reduce energy consumption.

3. Pressure Loss and Influencing Factors

As materials move through the pipeline, pressure gradually drops along the flow path—this is known as pressure loss. The magnitude of loss depends on the pipeline configuration, material characteristics, and flow velocity. Longer pipelines, smaller diameters, and rough internal surfaces all increase frictional resistance. Coarser or denser materials also heighten flow resistance, while bends, elbows, and junctions create local energy losses. When the gas-to-solid ratio is too low, insufficient airflow can cause material accumulation and blockages.

To reduce pressure loss, system design optimization is crucial. Selecting appropriate pipe diameters, ensuring smooth internal surfaces, and minimizing bends all help enhance efficiency. Maintaining a proper gas-solid ratio and steady flow velocity can further reduce energy use and equipment wear without compromising capacity.

4. Common Causes of Pressure Fluctuations

In theory, pneumatic conveying systems should maintain stable pressure. In practice, however, pressure fluctuations are common and usually stem from three aspects: material variability, equipment instability, and operational disturbances. For instance, higher material moisture increases stickiness and resistance; unstable compressor output or faulty valves lead to uneven air supply; and worn pipelines with rougher surfaces add to flow resistance over time.

Preventing such issues requires robust monitoring and maintenance. Regular checks of air sources, seals, and valves—combined with automated control systems for smooth airflow adjustment—help maintain pressure stability and reliable operation.

5. Pressure Variation in the Pressure Vessel (Blow Tank) System

The blow tank (pressure vessel) is one of the core components in a pneumatic conveying system. It acts as a buffer between the air source and the conveyed material. The stability of its internal pressure directly determines whether materials discharge smoothly. Blow tank pressure is affected by feed rate, discharge rate, air supply, and sealing conditions. Overfeeding or poor discharge can cause a rapid pressure rise, while excessive discharge or insufficient air supply can lead to pressure drops or even flow interruption.

To ensure stable operation, the control logic must coordinate feed and discharge cycles, keep air supply steady, and replace worn seals and valves in time to prevent leaks and pressure instability.

6. Applications and Advantages of Pneumatic Conveying

Thanks to its enclosed, safe, and highly automated nature, pneumatic conveying is widely used across industries.

- In food processing, it enables clean transport of materials like flour, sugar, and milk powder.

- In construction materials, it conveys cement, lime, and other bulk solids over long distances.

- In the chemical industry, it transfers PVC, resin, and other powders while preventing dust pollution.

- In power plants, it is the primary method for conveying coal dust and fly ash.

Compared with mechanical conveyors, pneumatic systems prevent material leakage, allow flexible pipeline routing within limited spaces, and enable unmanned, dust-free operations—supporting cleaner and smarter industrial production.

7. Conclusion

A pneumatic conveying system is like an “air express network” in industrial production, with pressure as the core driving force behind its efficiency. Proper pressure design determines not only throughput and energy consumption but also equipment longevity and system safety. During design, engineers must consider material properties, conveying distance, pipeline layout, and air source conditions to balance performance and cost while ensuring operational reliability. During operation, continuous pressure monitoring, regular maintenance, and intelligent control are equally essential.

Modern pneumatic systems increasingly adopt smart sensors, high-performance materials, and digital control technologies. With optimized piping, improved valve coordination, and predictive maintenance algorithms, new-generation systems achieve lower energy consumption, reduced wear, and fully automated monitoring and remote management.

In the future, pneumatic conveying will be more than a transport method—it will be an integral part of intelligent manufacturing. With higher efficiency, lower emissions, and greater reliability, it will continue driving the transition toward clean, safe, and sustainable industrial production—the true power behind green manufacturing.