Explosion-proof Vibrating Fork Level Switch: Working Principle, Technologies, and Industrial Applications

In the field of industrial automation, level detection is one of the most fundamental — and simultaneously one of the most critical — elements of process control. Among the available technologies, explosion-proof vibrating fork level switches play a vital role in applications involving flammable or explosive media, where they contribute directly to equipment safety, personnel protection, and the stable operation of entire production systems.

Among various point-level instruments, vibrating fork level switches are widely adopted across industrial sites due to their mature structure, well-established operating principle, and strong long-term stability.

However, with the rapid development of industries such as petrochemicals, coal chemicals, fine chemicals, and energy storage and transportation, production processes are evolving toward higher automation, greater energy density, and increased operational risk. Under these conditions, standard vibrating fork level switches have gradually revealed limitations when deployed in hazardous areas. Explosion-proof vibrating fork level switches have therefore become indispensable devices for modern industrial facilities.

Operating Principle and Fundamental Applications of Vibrating Fork Level Switches

Vibrating fork level switches are typical point-level detection instruments based on the monitoring of mechanical vibration characteristics. When the fork is in air or vapor, it vibrates at a stable natural frequency. Once immersed in liquid or covered by a high-density medium, the vibration is dampened, causing a measurable change in frequency and amplitude. The electronic module detects this variation and outputs a stable switching signal to indicate whether the medium has reached the preset level.

Because detection relies on mechanical vibration rather than electrical properties, measurement is largely independent of conductivity, dielectric constant, color, or transparency. No medium calibration is typically required. In addition, these devices demonstrate strong resistance to common process disturbances such as foam adhesion, surface turbulence, agitation, and pressure fluctuations, resulting in excellent repeatability and operational stability.

For these reasons, vibrating fork level switches have been extensively used in a wide range of industrial processes, including:

- Water and environmental engineering: High and low level alarms in reservoirs, tanks, and wastewater treatment units

- Chemical processing: Level control in reactors, buffer vessels, and intermediate storage tanks

- Food and beverage production: Applications requiring hygiene, reliability, and continuous operation

- Pharmaceutical and biotechnology processes: Systems with stringent requirements for consistency and process stability

- General industrial storage: Limit detection and overflow protection for various liquid media

In non-hazardous environments, standard vibrating fork level switches already meet most operational requirements, offering stable performance, high reliability, and low maintenance.

Special Requirements for Level Detection in Hazardous Environments

Industrial facilities handling flammable or explosive substances — such as crude oil, gasoline, solvents, LNG, alcohols, and light hydrocarbons — typically exhibit several risk factors:

- Continuous presence of flammable gases or vapors

- Frequent equipment start-stop cycles, where electrostatic discharge and transient energy cannot be ignored

- Extremely high requirements for electrical safety

- Strict compliance with safety regulations and certification systems

In such environments, any device capable of generating sparks or high surface temperatures may become a potential ignition source. Standard vibrating fork level switches, lacking explosion-proof design and certification, cannot satisfy these safety requirements and are therefore restricted or prohibited in hazardous zones.

Technical Foundations of Explosion-proof Vibrating Fork Level Switches

Explosion protection is not achieved simply by reinforcing an enclosure; it is the result of systematic safety engineering that ensures ignition energy is kept below the threshold capable of igniting hazardous atmospheres. The most widely recognized and reliable protection methods include the following.

Intrinsic Safety (Ex ia)

Intrinsic safety is based on energy limitation. Through carefully engineered circuitry, voltage, current, and stored energy are maintained below defined safety limits, ensuring that even under fault conditions the device cannot ignite an explosive mixture.

Key characteristics include:

- Suitable for high-risk areas such as Zone 0 and Zone 1

- High safety integrity with reduced system-level risk

- Requires use with intrinsic safety barriers or certified power supplies

Flameproof / Explosion-proof Enclosure (Ex db)

Flameproof protection utilizes a high-strength metallic enclosure to fully contain any sparks or high-temperature components. Even if an internal explosion occurs, the enclosure prevents flame propagation to the surrounding atmosphere.

Key characteristics include:

- Robust mechanical structure with strong environmental resistance

- Suitable for applications exposed to mechanical stress

- Requires strict adherence to installation and maintenance standards

Expanded Application Capabilities

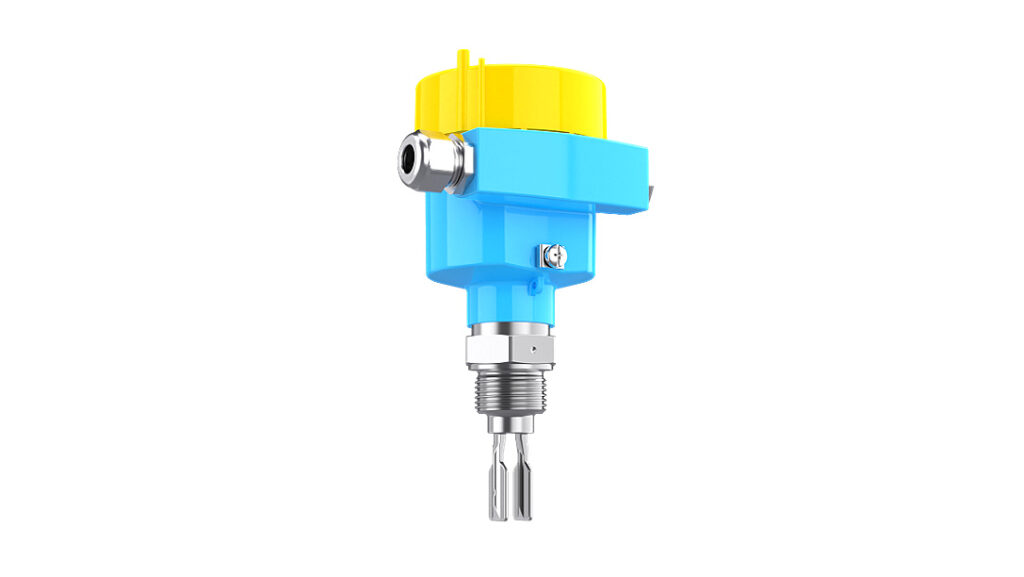

Represented by the Ring-11 explosion-proof vibrating fork level switch, Shenzhen Jiwei Automations Ltd has implemented systematic explosion-proof design across product structure, circuitry, and energy control to address the practical demands of hazardous environments. The device has obtained multiple explosion-protection certifications and supports several protection configurations:

Intrinsic Safety for Gas Atmospheres

Ex ia IIC T1…T6 Ga

Energy is strictly limited so that the device remains incapable of igniting explosive gas mixtures under both normal and specified fault conditions, making it suitable for Zone 0 and Zone 1 areas.

Flameproof Protection for Gas Atmospheres

Ex db IIC T6…T1 Gb

A high-strength enclosure fully contains potential ignition sources, preventing energy release into hazardous surroundings. Suitable for Zone 1 and Zone 2 environments.

Combined Gas and Dust Protection

Ex db IIC T6…T1 Gb + Ex tb IIIC T440°C…T80°C Db

Meets safety requirements for both explosive gases and combustible dust, making it appropriate for petrochemical plants, coal chemical facilities, energy storage sites, and processes with dust accumulation risks.

Through multi-mode certification, the Ring-11 can cover a broader range of hazardous area classifications and media types, providing engineers with greater flexibility in system design and higher safety redundancy.

Users can select the appropriate protection method based on risk classification, system architecture, and site compliance requirements.

Typical applications include — but are not limited to:

- Crude oil, refined fuel, and chemical storage tanks

- Gasoline, diesel, and lubricating oil tank farms

- LNG storage and transfer pipelines

- Reactors and buffer tanks containing flammable solvents

- Critical level interlock points within petrochemical installations

In these scenarios, explosion-proof vibrating fork level switches serve not only as measurement devices but often as integral components of safety instrumented functions, directly supporting overflow prevention, dry-run protection, and leak mitigation strategies.

Engineering Value and Long-term Operational Advantages

From an engineering perspective, the value of explosion-proof vibrating fork level switches extends beyond their suitability for hazardous areas. Their long-term operational benefits include:

- Simple detection principle with strong resistance to interference

- Minimal dependence on medium properties, enabling broad applicability

- Clear switching outputs for seamless integration into DCS and SIS architectures

- Extended maintenance intervals that help reduce lifecycle costs

As modern industrial facilities increasingly prioritize intrinsic safety, system reliability, and regulatory compliance, explosion-proof vibrating fork level switches have evolved from optional instruments into standardized components within many high-risk processes.

Conclusion

As industrial plants continue to scale up while operating under higher continuity and risk levels, the safety attributes of level instrumentation are being evaluated with equal — if not greater — importance than measurement performance itself.

By combining a proven vibration-based detection principle with rigorous explosion-protection engineering, explosion-proof vibrating fork level switches provide hazardous industries with a reliable, verifiable, and durable solution for level control — supporting safer and more stable process operations over the long term.