Jiwei Product Development Process: From Concept to Mass Production

In today’s highly competitive market, a scientific and efficient product development process is essential for business success. Jiwei, as a leading manufacturer specializing in level instruments and process automation instruments, adheres to a customer-oriented approach, continuous innovation, and strict quality management. Jiwei is committed to providing high-quality, reliable level switches, level transmitters, and other intelligent instruments for global customers. This article details Jiwei’s comprehensive product development process, from concept to mass production, supporting businesses to achieve efficient delivery and continuous innovation.

1. Overview of Jiwei’s Product Development Process

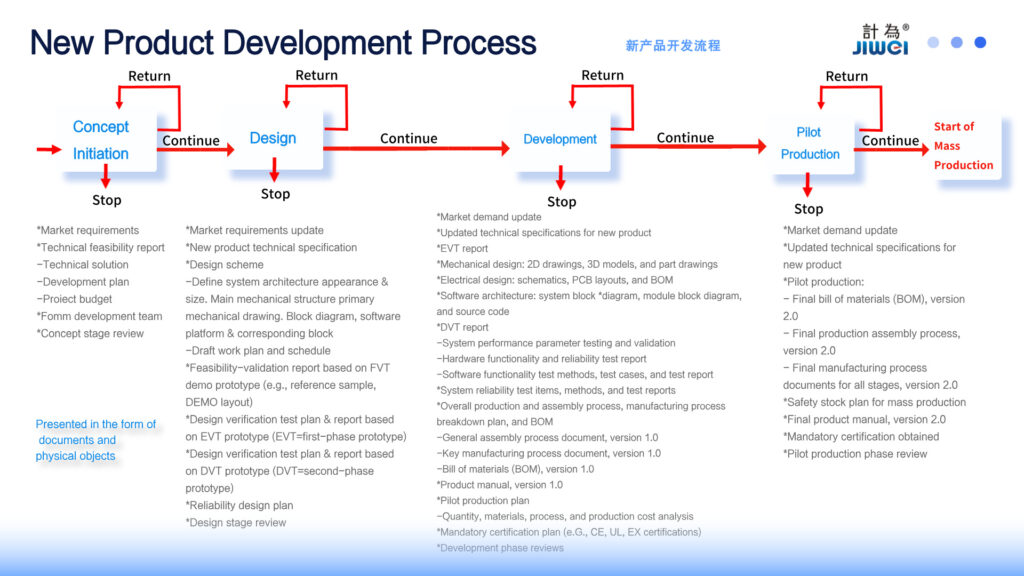

Jiwei’s product development process typically includes five key stages: concept proposal, design, development, pilot production, and mass production. Each stage features rigorous reviews to ensure the project meets market demand and technical feasibility. The stages are as follows:

1. Concept Proposal Stage

At this stage, Jiwei analyzes market demands and industry trends to propose innovative product concepts for level instruments. The team develops initial solutions and project plans, clearly defining objectives and expected results. If requirements are not met, the concept is revised, improved, or even redeveloped. If market, technology, or financial conditions change, or if the project becomes less feasible or meaningful, the project may be stopped. Only qualified concepts move to the next stage.

2. Design Stage

The design stage involves system architecture, appearance dimensions, and technical solution design. A functional verification prototype (FVT) is produced to verify feasibility. If verification fails, the process returns to the previous step for improvement. Upon passing the review, the project continues to the development stage.

3. Development Stage

The development stage includes detailed system design, circuit design, software programming, and module integration. Jiwei produces 2–3 engineering verification prototypes (EVT) to verify technical feasibility and main performance indicators. Subsequently, more than 10 design verification prototypes (DVT) are manufactured to test product performance consistency and reliability. Detailed test reports are generated, and initial manufacturing and test process documents are prepared for mass production.

4. Pilot Production Stage

During pilot production, Jiwei carries out small-batch manufacturing to further verify consistency and reliability. Production and testing processes are refined, a complete production line workflow is established, and manufacturing and testing documents for mass production are finalized. In this stage, products also obtain various required certifications to comply with industry standards and regulations.

5. Mass Production

After passing all validations and optimizations, Jiwei’s level switches, level transmitters, and other products officially enter mass production and are launched to the market, continuously delivering value to customers worldwide.

2. Review Mechanism and Decision Process

At the end of each stage, the project team conducts strict reviews, resulting in three possible decisions:

- Return: Requirements are not met; improvements or rework are needed.

- Continue: Work is qualified, and the project moves to the next stage.

- Stop: Major changes in market, technology, or finance, or decreased feasibility/meaning; the project is terminated.

This clear, stage-gated review mechanism ensures effective risk management and efficient resource allocation.

3. The Value and Significance of the Product Development Process

- Ensuring Product Quality: Stage reviews and multiple rounds of prototype testing minimize technical and quality risks.

- Shortening Development Cycles: Process management enhances team collaboration and accelerates time-to-market.

- Driving Continuous Innovation: Combining market needs with technological trends fosters ongoing product upgrades and innovation.

- Compliance Assurance: Strict certification processes ensure products meet international and industry standards.

Conclusion

A scientific and rigorous product development process is the cornerstone of Jiwei’s sustainable development. By standardizing every step and strictly controlling each review, Jiwei stands out in the competitive market, efficiently transforming product concepts into mass-produced solutions, and continuously creating greater value for customers and society.