Radar Level Measurement: Precision and Reliability in Industrial Applications

Radar level measurement is one of the most reliable and accurate technologies for monitoring liquid and solid levels in industrial processes. Unlike traditional level measurement methods, radar technology provides precise, non-contact measurement, ensuring stable performance in harsh environments. This makes it an ideal choice for industries such as chemical processing, oil and gas, food production, and wastewater treatment.

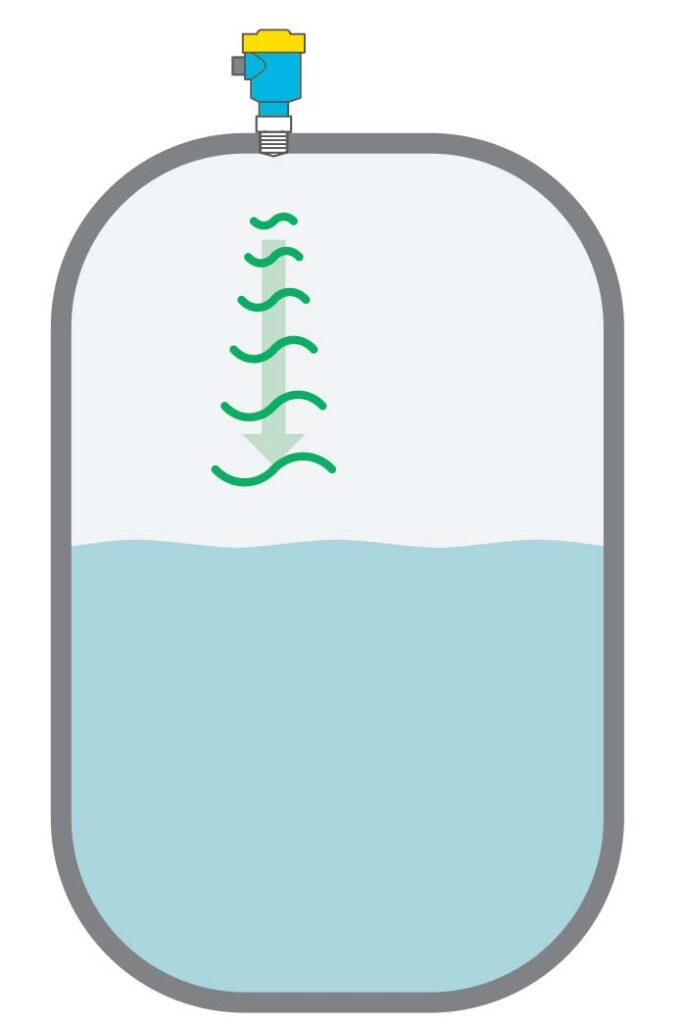

How Radar Level Measurement Works

Radar level meters operate by emitting microwave signals towards the measured medium. The signals are reflected back to the sensor from the material surface, and the time taken for the signals to return is used to calculate the distance. With this data, the sensor determines the exact level of the material. This measurement process is highly efficient and remains unaffected by environmental conditions such as temperature fluctuations, dust, or vapor.

Advantages of Radar Level Measurement

1. Non-Contact and Maintenance-Free

Radar level measurement does not require physical contact with the measured substance, preventing wear and contamination. This non-contact feature ensures longevity and minimal maintenance, making it highly cost-effective over time.

2. High Precision and Reliability

Radar sensors provide exceptional accuracy, even in challenging conditions such as high temperatures, extreme pressures, or aggressive chemicals. This precision enhances process efficiency, reduces material waste, and improves overall safety.

3. Adaptability to Various Materials

Whether measuring corrosive liquids, powders, or granular solids, radar level meters adapt to different process conditions. Jiwei’s radar level meters, for example, use advanced signal processing to ensure stable measurement across multiple industries, even in environments with heavy dust or foam.

4. Unaffected by Process Conditions

Unlike ultrasonic or mechanical measurement methods, radar level meters are not impacted by temperature variations, pressure changes, or material buildup. This ensures consistent performance in all applications, even in extreme conditions such as cryogenic tanks or high-pressure reactors.

5. Long-Range Measurement Capabilities

Radar level meters can accurately measure levels in tanks and silos up to 30 meters or more, making them suitable for applications requiring long-distance measurements. This capability is particularly valuable in industries like cement, mining, and petrochemicals.

Jiwei’s Radar Level Measurement Solutions

Jiwei’s radar level meters integrate state-of-the-art 80GHz radar technology with intelligent processing algorithms. These meters offer superior performance in complex industrial applications, including highly reflective surfaces and low dielectric materials. Additionally, Jiwei provides Bluetooth connectivity via its Jiwei Smart Control app, allowing for wireless configuration and real-time monitoring.This innovative feature is unique in the industry, far surpassing competitors, greatly enhancing the convenience and real-time capabilities of the equipment.

Jiwei’s radar level meters are ensuring high reliability in safety-critical applications. The compact design and intuitive user interface simplify installation and commissioning, reducing downtime and improving operational efficiency.

Choosing the Right Radar Level Meter

Selecting the correct radar level meter depends on factors such as tank height, dielectric constant of the material, and process conditions. Jiwei’s product line offers solutions tailored for high-temperature applications, corrosive substances, and dusty environments. When choosing a radar level meter, consider:

- Process Temperature and Pressure: Jiwei’s high-temperature radar meters handle extreme conditions up to 250°C.

- Material Dielectric Constant: Low dielectric materials require advanced radar technology for accurate readings.

- Silo or Tank Height: Jiwei’s radar meters provide accurate measurements even in large storage silos.

- Explosion-Proof Requirements: For hazardous environments, Jiwei offers explosion-proof models to ensure safety compliance.

Applications of Radar Level Measurement

Radar level meters are widely used in various industries due to their versatility and reliability. Common applications include:

- Oil & Gas: Measuring crude oil, refined fuels, and chemicals in storage tanks.

- Food & Beverage: Ensuring precise level monitoring in dairy, brewing, and beverage production.

- Cement & Mining: Monitoring solid materials such as clinker, coal, and limestone.

- Water & Wastewater Treatment: Managing water levels in treatment plants and reservoirs.

- Chemical Processing: Handling highly reactive and corrosive chemicals in tanks and reactors.

Conclusion

Radar level measurement is an advanced and highly reliable solution for industrial level monitoring. With non-contact measurement, high accuracy, and adaptability to extreme conditions, radar technology outperforms traditional level measurement methods. Jiwei’s radar level meters, featuring 80GHz technology, adaptive technology, and intelligent processing, provide industry-leading solutions for precise and efficient level measurement. Whether used in chemical plants, storage tanks, or food processing facilities, Jiwei’s radar solutions ensure optimal process control and safety.