Radar Level Meter: Why Dielectric Constant Is a Key to Accuracy

Radar Level Meter accuracy is no trivial matter in engineering. In sectors like chemical processing, petroleum storage, and wastewater treatment, precise monitoring of material levels inside tanks and pipelines is critical to ensuring both safety and operational efficiency.

Early systems relied on manual checks or simple float-type switches. With the evolution of automation, ultrasonic and pressure-based transmitters became common. Eventually, radar level meters emerged as the modern standard. In essence, radar emits electromagnetic waves into a container, captures their echo, and calculates the surface position based on the reflection.

What Is Dielectric Constant?

The dielectric constant describes a material’s ability to become polarized when exposed to an electric field, directly influencing how it stores and transmits electrical energy. Imagine the material as a pot of soup, the electric field as a spoon, and the molecules as pepper flakes—some move vigorously, others barely react. The higher the dielectric constant, the stronger the material’s interaction with the field.

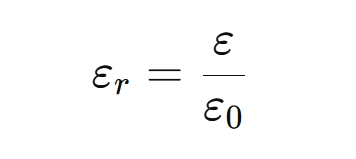

Engineers typically refer to the relative dielectric constant (εr), which is measured against a vacuum baseline (ε₀ = 8.854×10⁻¹² F/m).

Examples of common materials:

- Air ≈ 1

- Glass ≈ 4

- Water ≈ 80

- Diesel ≈ 2–3

- PTFE ≈ 2.1

Variations in dielectric constant stem from molecular polarity, structural factors, temperature, and electromagnetic frequency. For radar level applications, dielectric constant often plays a more critical role than density or viscosity.

Dielectric Constant and Wave Reflection

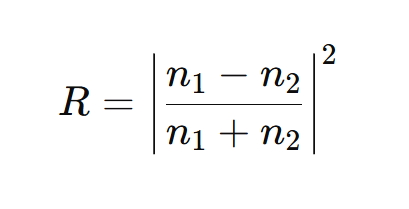

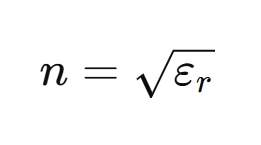

Radar level meters rely on how electromagnetic waves reflect off surfaces. The reflection strength depends on the dielectric contrast between air and the medium. The reflection coefficient (R) can be calculated as:

This means materials with higher dielectric constants provide stronger reflected signals, making detection easier and more stable.

| Material | εr | Reflection (%) |

|---|---|---|

| Air | 1.0 | 100 |

| Water | 80 | 74.7 |

| Diesel | 2.1 | 4.1 |

| Glass | 4.0 | 11.1 |

| Ceramic | 9.0 | 25 |

As the table shows, highly polar substances reflect radar waves effectively, whereas media with low dielectric constants may cause weak or unstable signals.

Radar Level Meters: The “Telescopic Eye” of Modern Industry

Radar level meters emit high-frequency microwaves into vessels. When these waves encounter a surface, part of the energy is reflected. By measuring the time interval between emission and return, the system calculates the distance to the material surface, similar in principle to sonar but based on electromagnetic signals.

Because the strength of the reflected signal depends on dielectric constant, radar manufacturers typically specify a minimum εr requirement. If the medium’s εr is too low, echoes become too weak, leading to unreliable results.

Field Challenges: Foam, Sludge, and Complex Media

Real-world conditions often involve far more complexity than clean homogeneous substances. In applications such as leachate ponds or aeration tanks, the surface layer may consist of foam with low εr, distorting or blocking reflections. In fermentation tanks or silos, layered buildup or mixed-phase materials further weaken or scatter the signal.

A radar sensor that performs perfectly in clean water can struggle in the presence of oil-based substances, slurries, or emulsions. Understanding this helps engineers avoid relying solely on datasheets—field verification of dielectric properties is key to successful deployment.

Physics First: Respecting Material Properties

No matter how advanced radar algorithms become, they cannot override the fundamental physics of electromagnetic reflection. Choosing high-end equipment without considering material compatibility often results in poor performance.

Seasoned engineers always combine theoretical knowledge with field experience. Verifying conditions on-site and evaluating material properties ensure that radar level measurement systems perform with stability, precision, and long-term reliability.

radar level measurement, dielectric constant, industrial tank monitoring, electromagnetic wave reflection, radar level sensor, foam interference, εr radar measurement, accurate level detection