Accurate Measurement of Piezoelectric Ceramic Capacitance in Liquid Level Switches

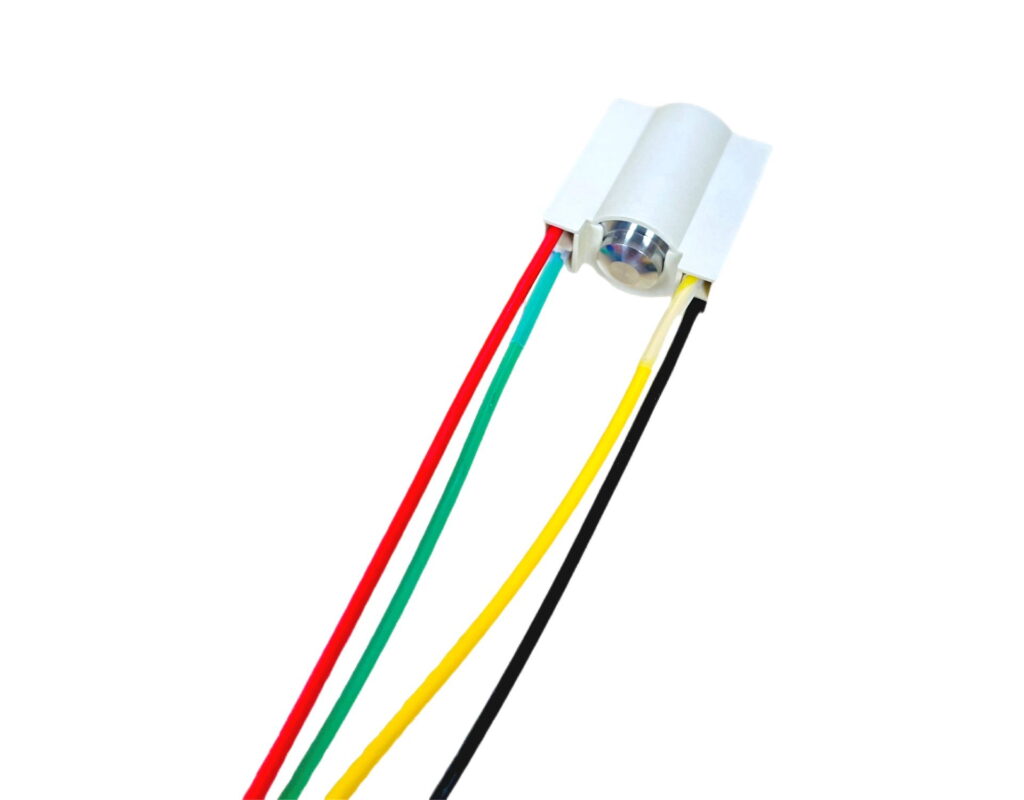

In the core structure of a liquid level switch, the piezoelectric ceramic element plays a critical role in generating and detecting vibrations. This component drives the fork probe to oscillate mechanically and senses changes in its vibration status, converting them into electrical signals for analysis by the system. To ensure accurate level measurement under powder and granular material conditions, it is essential to precisely measure and control the key parameter of piezoelectric ceramics—static capacitance.

Importance of Piezoelectric Ceramic Capacitance

Static capacitance is one of the most vital performance indicators of a piezoelectric ceramic. It reflects the dielectric characteristics of the material and is directly influenced by its dielectric constant, geometric shape, thickness, and electrode area. In the quality control of liquid level switches, managing the capacitance range of the ceramic elements ensures consistent product performance and long-term reliability. This prevents vibration errors or operational failures due to capacitance deviations.

How to Accurately Measure Piezoelectric Ceramic Capacitance?

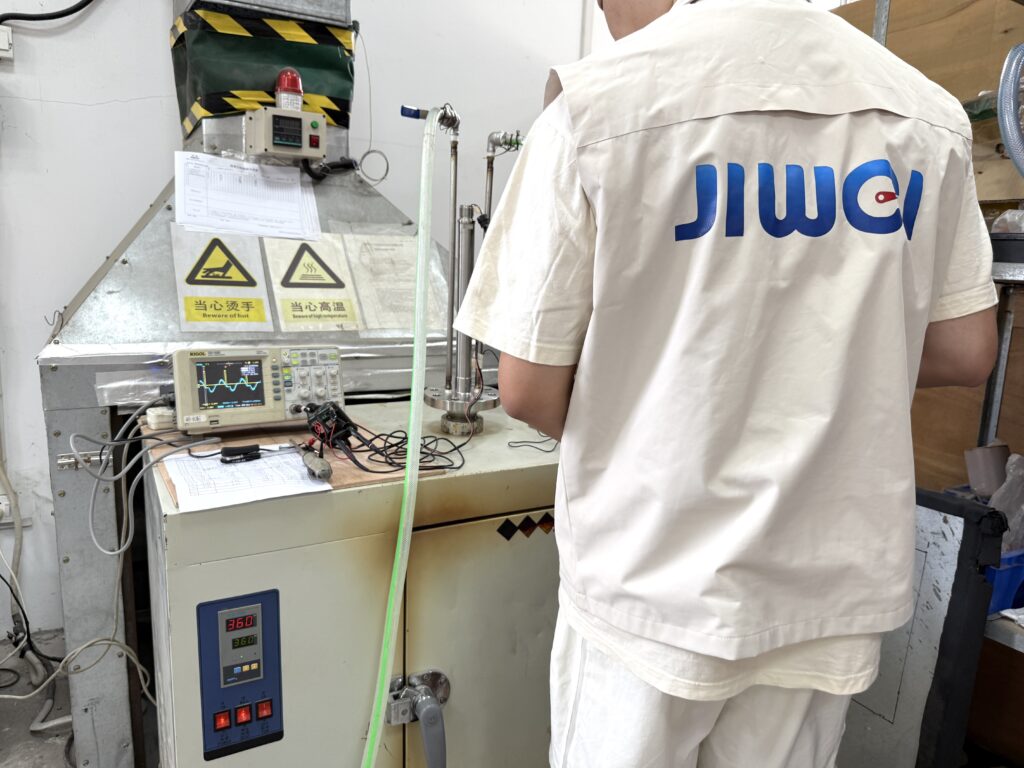

To achieve high accuracy and repeatability in capacitance measurements, Jiwei Automations uses an LCR digital bridge as the standard testing equipment in the development and production of Ring-11 and other liquid level switch models.

The LCR meter is a precision instrument for measuring inductance (L), capacitance (C), and resistance (R). It offers high resolution and stability at high frequencies, making it particularly suitable for detecting the small capacitance values of piezoelectric ceramics—typically in the picofarad (pF) range.

The Impact of Fixture Design on Measurement Stability

Piezoelectric ceramic capacitance can vary under mechanical pressure. To minimize stress-induced measurement error, Jiwei developed a custom-designed piezoelectric ceramic fixture made of high-conductivity copper plates and an insulating support body.

Measurement steps include:

- Place the ceramic disc between the copper plates of the fixture.

- Connect the LCR meter’s test clips to the two electrodes of the fixture.

- Set the LCR meter to a test frequency between 1kHz and 10kHz (commonly 1kHz), using C-D (capacitance and dissipation factor) mode.

- Wait 10–30 seconds for the reading to stabilize and record the final capacitance value.

Handling Capacitance Fluctuations During Measurement

During real-world testing, especially in environments with high humidity or air turbulence, the ceramic surface can absorb moisture, causing unstable readings. To address this, Jiwei’s R&D team established a proven procedure:

- Wait for the fluctuation to narrow within ±3%;

- Record the highest and lowest values in the last two digits;

- Take the average as the final reading.

For instance, if the measured value fluctuates between 1562 and 1596 pF, the final result is recorded as 1579 pF. This method balances efficiency and accuracy and is commonly used in industrial measurement practices.

Real-World Application: Enhancing Liquid Level Switch Performance

In its Ring-11 liquid level switch series, Jiwei applies a dual piezoelectric ceramic design for excitation and detection. The capacitance tolerance of each ceramic disc is strictly maintained within ±3% to ensure optimal probe amplitude and sensitivity.

Ring-11’s dual-ceramic structure ensures stable fork vibration and high sensitivity, particularly important for measuring lightweight materials like foam granules or resin powder. This precision greatly reduces false alarms caused by ceramic inconsistencies and boosts overall reliability.

Conclusion: Foundational Measurements Define Product Quality

Although piezoelectric ceramics are tiny components, their capacitance measurement determines the vibration performance and measurement accuracy of liquid level switches. It is also a critical quality control step for ensuring batch consistency in level instrument manufacturing.

Jiwei Automations remains committed to the philosophy of “data over guesswork, testing over assumptions.” Every liquid level switch undergoes rigorous capacitance screening before shipment, ensuring long-term performance and industrial-grade reliability for customers.