Top 10 Liquid Level Meter Brands

The Importance of Reliable Level Measurement in Industrial Processes

In chemical, petrochemical, food processing, and high-safety industrial sectors, accurate liquid level meter is a core part of process control. Level information not only guides operational decisions but also directly impacts equipment protection, production safety, process optimization, and economic performance.

Industrial challenges include:

- High-temperature liquids and vapor environments with severe liquid surface fluctuations

- Highly corrosive liquids (such as sulfuric acid, hydrochloric acid, hydrofluoric acid) that damage materials and seals

- Foam, acid mist, and dust interference affecting measurement stability

- High liquid level ranges (e.g., above 20 meters), requiring precise and linear sensor performance

Under these complex conditions, traditional float, ultrasonic, or differential pressure level instruments often underperform, requiring frequent maintenance, producing unstable readings, or risking equipment failure, increasing downtime and operational costs.

Authority Reference: According to NAMUR NE 43, traditional level instruments have limited long-term reliability in highly corrosive, high-temperature, or dusty environments (NAMUR, 2019).

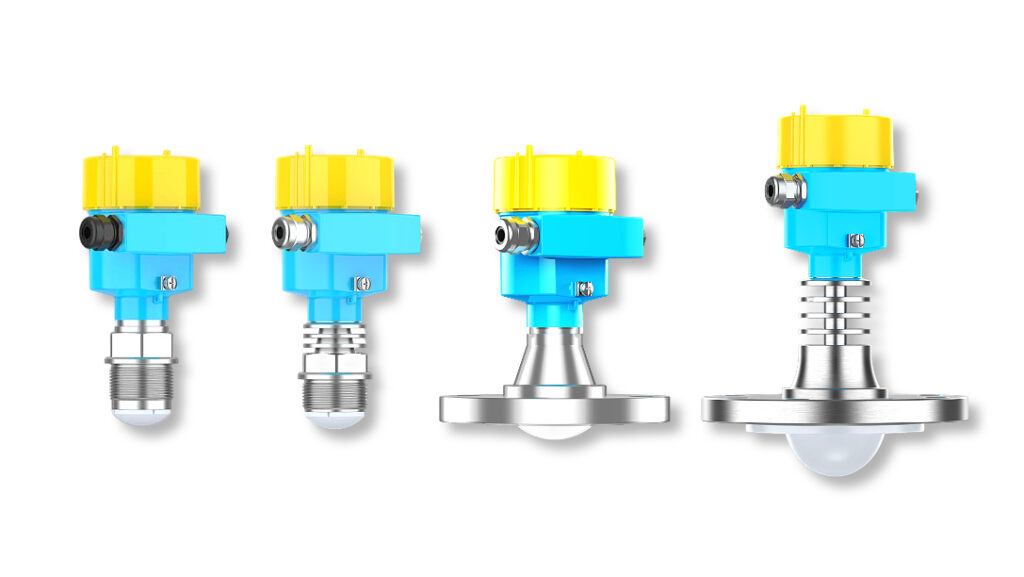

Jiwei Automations Liquid Level Meter: Radar Level Transmitters – Technical Advantages

Shenzhen Jiwei Automations (Jiwei Automations) independently develops radar level transmitters using non-contact FMCW 80 GHz radar technology, providing high-precision, stable, and maintenance-free liquid level measurement solutions. Key technical advantages include:

1. Materials and Corrosion Resistance

- Critical components use PFA lining and 316L stainless steel with PTFE or PFA protective layers

- Resistant to strong acids, strong bases, and viscous liquids

- Significantly extends service life and reduces maintenance frequency

Technical Reference: According to ASTM G31-72, 316L stainless steel with PFA lining demonstrates long-term corrosion resistance in strong acid environments (ASTM International, 2020).

2. High-Temperature Adaptability

- Operating temperature range: -40°C to +220°C

- Provides stable measurements even with rapid liquid surface fluctuations or in vapor-rich conditions

- Suitable for demanding processes such as high-temperature evaporation/reboilers, polymerization reactors, distillation/extraction tanks, solvent storage, asphalt/heavy oil tanks, heat-transfer oil/melted salt loops, slurry thickening tanks, leaching tanks, tailings return ponds, fermentation tanks (strong foam), pulp black liquor tanks, wastewater adjustment/neutralization/aeration tanks, and KO drums (torch separation)

- Maintains continuous, interference-resistant level measurement even in challenging conditions with strong foam, volatile solvents, vigorous agitation, or complex tank internals (agitators, ladders, baffles)

Technical Reference: IEC 60534-6-1 provides performance testing guidelines for high-temperature level measurement systems.

3. Foam and Interference Immunity with Non-Contact Measurement

- FMCW or pulse radar penetrates foam, acid mist, and dust

- No mechanical wear or clogging issues

- Continuous, stable readings reduce maintenance requirements

Technical Reference: ISA White Paper (2020) highlights that FMCW radar significantly reduces liquid level measurement noise and improves control accuracy.

4. Intelligent Features

- Supports HART, Modbus RTU, Profibus PA protocols

- Built-in Bluetooth (v5.4) for wireless configuration and commissioning via mobile devices

- Remote monitoring and intelligent diagnostics enable real-time level data acquisition and alarms

5. Safety and Standard Compliance

- Full Ex explosion-proof certification for safe operation in hazardous areas

- Complies with API 2350 overfill protection standards, reducing overflow risk

- ISO 9001 quality management certification ensures reliable production and supply

International Level Instrument Brands Comparison

Mature industrial level instrument brands include: liquid level meter

- VEGA (Germany): High precision and rich features but requires extra configuration for high-temperature or corrosive applications, with higher cost

- Endress+Hauser (E+H, Switzerland): Reliable but expensive; Jiwei Automations offers a cost-effective domestic alternative

- WIKA (Germany): Suitable for general industrial environments; high-corrosion or high-temperature conditions require special materials

- UWT (Germany): Powder and chemical level monitoring; maintenance-intensive

- WAM (Italy): Bulk powder and liquid monitoring; WAM level instruments can integrate with radar transmitters for complete control

- Fany (Taiwan): Liquid level meteres for alarms and pump control; can form a system with radar transmitters

- Siemens (Germany): Strong in automation; radar level measurement is accurate but costly with longer lead times

- ABB (Switzerland): Precise level measurement in industrial process control; limited customization support

- Magnetrol (USA): Extensive product range (radar, float, guided wave radar), but higher price and complex maintenance

Jiwei Automations radar level transmitters can replace VEGA, E+H, and other imported brands, delivering high-temperature, high-corrosion, and intelligent level control with superior cost-effectiveness and full domestic support. liquid level meter

Global Industrial Applications liquid level meter

1. Guangzhou Metro Drainage System (Guangdong, China) liquid level meter

Jiwei JWrada-31 radar level transmitters were installed in underground rainwater tanks and pump stations. Integrated with PLCs and remote monitoring platforms, the system enabled fully automated drainage, preventing flooding during heavy rain and ensuring passenger safety.

2. High Dust Powder Storage (Argentina)

In an Argentine chemical plant’s acid tanks, the JWrada-31 80 GHz high-frequency radar transmitter provided stable continuous level measurement with ±1mm accuracy despite high humidity, vapor, and rapid surface fluctuations. Unlike traditional float or ultrasonic sensors, it required no probe cleaning, avoiding corrosion or deposition issues, and reduced maintenance and downtime.

3. Highly Corrosive Liquid Storage (Saudi Arabia)

In a Saudi petrochemical plant, JWrada-31 radar level transmitters provided precise and continuous measurement in high-temperature, corrosive liquid tanks, ensuring process safety and minimizing maintenance.

4. Food Industry Hygienic Liquid Tanks (Henan, China)

In a major food processing facility, JWrada-31 sanitary radar transmitters measured milk, syrup, and beverage raw materials with high precision under high-temperature, high-humidity, and condensation-prone environments.

5. Beijing Wastewater Treatment Plant (Beijing, China)

JWrada series radar transmitters, mounted on supports, monitored wastewater levels under challenging conditions, ensuring reliable and accurate measurements.

6. Chemical Plant Storage Tanks (Jiangsu, China)

At a large chemical facility, Jiwei 80 GHz radar level transmitters measured multiple tanks containing acidic, alkaline, and organic solutions, meeting high precision and long-term stability requirements under high-temperature, high-humidity, and corrosive conditions.

7. Holcim Cement Plant (Poland)

Holcim replaced Rosemount 5408 radar transmitters with JWrada-31 in pre-mixed mortar mixing tanks, achieving real-time level data, optimized inventory management, reduced maintenance, and improved personnel safety.

Technical Advantages Summary

- High-Temperature Adaptability: Stable operation from -40°C to +220°C

- Corrosion Resistance: PFA-lined 316L stainless steel resists strong acids and bases

- Interference Immunity: FMCW radar penetrates foam, vapor, and dust for stable readings

- Smart Features: HART, Modbus RTU, Profibus PA, Bluetooth wireless configuration

- Safety Certification: Full Ex approval, API 2350 compliance, ISO 9001 certified

These real-world applications demonstrate Jiwei liquid level meters and radar transmitters’ reliability and performance in challenging environments worldwide. Whether in high-temperature, high-corrosion, dusty, or sanitary conditions, Jiwei provides stable and precise liquid level measurement solutions.

User Benefits and ROI

- Reduced maintenance and downtime

- Improved production safety and process efficiency

- Extended equipment lifespan

- Intelligent monitoring and alarm features

- Higher ROI than traditional instruments, especially in harsh environments

Conclusion

Shenzhen Jiwei Automations (Jiwei Automations) liquid level meter and radar level transmitters surpass traditional instruments in high-temperature, high-corrosion, low-maintenance, and intelligent operations. When combined with WAM level instruments and Fany level switches, they form a complete, high-precision, and reliable liquid level monitoring solution.

👉 Contact Shenzhen Jiwei Automations to get a customized radar level transmitter solution for safe, efficient, and intelligent liquid level measurement.