Chemical Equipment Is More Than Just “Metal Tanks”: A Must-Read for Technicians

The reason the chemical industry can operate in a stable, large-scale, and long-cycle manner is not merely due to process packages, but because of the equipment systems capable of withstanding high temperature, high pressure, corrosion, erosion, multiphase flow, and highly complex reaction conditions over long periods. Chemical Equipment

Chemical equipment is not just “hardware”—it is an integration of reaction engineering, thermodynamics, fluid mechanics, materials science, safety engineering, and control systems. The design, manufacturing quality, and operating behavior of this equipment ultimately define the upper limit of any plant.

1. Reaction Equipment

Reactor Vessels

Widely used in batch or semi-continuous processes, reactor vessels enable mixing, reaction, heating, cooling, dispersion, or dissolution. Agitators create flow patterns for uniform contact and stable heat and mass transfer. Heat is exchanged via jackets or internal coils.

Structure

A typical reactor includes a cylindrical body, head, shaft, impellers, baffles, and jackets/coils. Different impeller types produce distinct flow fields:

- Propeller impellers: Strong axial circulation; used for low–medium viscosity or solid suspension.

- Rushton turbines: Strong radial flow; ideal for gas–liquid dispersion.

- Anchor/frame impellers: For high-viscosity media; improve near-wall mixing.

Common operating issues

- Insufficient heat transfer or slow temperature response

- Local hot spots during exothermic reactions

- Increasing viscosity causing poor heat removal

Typical signs of failure

- Abnormal motor load, vibration, mechanical seal leakage

- Product color changes or impurity increase

- Heating/cooling time gradually extending

Understanding the interplay of mixing–heat transfer–property changes is essential for judging reactor behavior.

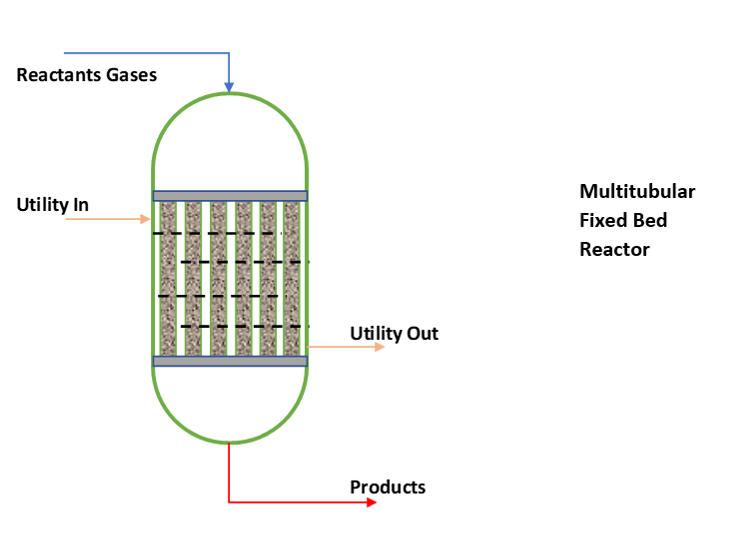

Tubular and Fixed-Bed Reactors

Used for continuous processes requiring precise residence time or catalyst-driven reactions.

Principles

- Tubular reactors: Near plug flow; temperature controlled via wall heat transfer.

- Fixed-bed reactors: Feed passes through a catalyst bed; heat release and pressure drop vary along the bed.

Typical phenomena

- True plug flow is rarely achieved; residence time distribution and radial gradients exist.

- Pressure drop increases over time due to fouling.

- Catalyst deactivation is often non-uniform.

Typical issues

- Sudden pressure drop rise: inlet strainer blockage or coking

- Temperature shifts: maldistribution or catalyst aging

- Declining conversion: long-term deactivation or distributor failure

Trend data of temperature–pressure drop–flow is more meaningful than single readings.

2. Columns

Tray Columns

Used in distillation, absorption, and stripping.

Operating windows

- Low load: Weeping, low efficiency

- High load: Flooding, large pressure drop

- Normal: Stable froth, effective mass transfer

Key checks include pressure drop trends, top/bottom temperature response after adjusting reflux, and abnormal temperature points that do not improve with tuning.

Typical issues

- Flooding: pressure spike, unstable overhead temperature

- Weeping: persistently low efficiency

- Internals damage: tray deformation or downcomer blockage

Packed Columns

Used in vacuum or low-pressure applications requiring high theoretical stages.

Efficiency depends heavily on liquid distribution.

Poor distribution causes dry/wet zones and large efficiency losses.

Check for:

- Persistent need to increase reflux

- Abnormal pressure drop trends

- High sensitivity of product quality to load changes

Inspection during shutdown provides useful confirmation of operation trends.

3. Heat Exchangers

Shell-and-Tube Exchangers

The most common type, used for heating, cooling, condensing, and reboiling.

Key operating indicators Chemical Equipment

- Heat-transfer decline: smaller temperature approach; longer heating/cooling time

- Pressure drop changes: gradual = fouling; sudden = blockage or bypass

- Leakage: cross-contamination or unexpected material balance changes

Cooling-water iron ion increases often signal tube leakage.

Plate Heat Exchangers

High efficiency but sensitive to fouling and gasket aging.

Common issues include:

- Gasket failure → external leaks

- Particle deposition → channel blockage

- Internal leakage → contamination

Frequent tightening, unusual fouling, or cross-contamination signals performance decay.

4. Storage and Transport Equipment

Pressure Vessels and Tanks

Used for storage, phase separation, buffering, and material handling.

Key areas to monitor:

- Weld seams, corrosion, wall thickness

- Foundation settlement, tank bottom corrosion

- Breather valve operation, top water accumulation

- Static electricity prevention

Check whether pressure, temperature, and liquid level follow expected logic. Chemical Equipment

Pumps, Compressors, and Piping Chemical Equipment

Provide the driving force for fluid transport.

Typical problems

- Pump cavitation due to low suction pressure

- Pipe vibration at weak supports or sharp elbows

- Weld fatigue under high temperature/corrosive conditions

Focus on

- Suction pressure & temperature (cavitation early warning)

- Bearing/seal temperature & vibration trends

- Pipe supports and thermal expansion clearance

Consistent inspection records are crucial.

5. Solid Handling Equipment

Centrifuges

Rely on centrifugal force for solid–liquid separation.

Common issues:

- Feed fluctuations increasing vibration

- Filter cloth blockage increasing moisture

- Rotor imbalance accelerating bearing wear

Monitor vibration trends, motor load, filtrate clarity, and cake quality.

Pneumatic Conveying

Uses air flow to transport powders.

Common problems include elbow erosion, moisture-induced clogging, and pressure fluctuations.

- Low velocity → accumulation

- Excess velocity → erosion

Watch for repeated blockages, abnormal noise, and pressure deviations.

6. Materials and Corrosion Engineering

Key engineering concerns

- Corrosion & material selection

Choosing the right material is often the hardest part.

Examples: Hastelloy for chlorides, Monel for HF, 904L/Zr for strong oxidizers, PTFE liners for viscous corrosives, glass-lined reactors for many acids. - Fatigue & thermal cycling

Repeated start–stop and temperature changes accelerate weld cracking. - Maintainability

Even excellent equipment will degrade quickly if difficult to clean or inspect. - Spare parts availability

Are internals standard or custom? Can they be replaced quickly? - Dynamic risk & HAZOP

Equipment is part of the plant’s risk system, not just a standalone asset.

Tracking corrosion locations and trends helps assess material suitability.

7. Dynamic Operating Conditions Chemical Equipment

Dynamic behavior reveals whether equipment can withstand real-world disturbances.

Key observations: Chemical Equipment

- Column pressure-drop response to load changes

- Reactor cooling capacity during upset

- Liquid backflow after pump trip

- Sequence of temperature and flow jumps

Replay of event trends can help build operational intuition.

Conclusion

Chemical equipment may appear cold and metallic, but it embodies the entire understanding of industrial engineering: Chemical Equipment

Reaction kinetics, heat/mass transfer, corrosion, flow distribution, structural strength, control logic, safety, and operational economics.

The chemical industry is evolving—toward finer design, smarter equipment, advanced materials, and greener processes.

Chemical equipment is the carrier and bridge of all these transformations.