Tank Level Meter Selection Guide: Integrated Analysis of Process, Safety, and Cost

In chemical plants and various production workshops, storage tanks serve as key equipment for material storage, buffering, and blending. Accurate and stable measurement of tank liquid levels is fundamental for production monitoring, safety risk prevention, and trade settlement, particularly in tank farm operations.

1. Importance of Liquid Level Data

From a production perspective, liquid level data directly affects process continuity and unit load control. In continuous reactors or storage tanks, material supply, reflux rates, and pump operations rely on real-time liquid level information. Inaccurate or delayed measurement may cause underfeeding, process fluctuations, or load anomalies, threatening production safety and product quality.

From a safety standpoint, liquid level abnormalities are often the root cause of incidents. Overfilling can lead to spills, foam overflow, or backflow; underfilling may result in pump dry-running, heater dry burn, or abnormal chemical reactions. In high-temperature, high-pressure, or flammable environments, liquid level incidents can pose serious safety risks.

From a management and trade settlement perspective, accurate liquid level measurement impacts economic efficiency and compliance. For oil, chemical raw materials, and finished products, tank levels often form the basis for volumetric measurement. Any deviation can result in financial losses or trade disputes. Traceable and reliable liquid level data is especially critical in tank farm metering and batch settlement.

Therefore, selecting a tank level meter is not a matter of “just fitting it in”—it is a system engineering task that must balance material properties, process conditions, safety requirements, and lifecycle costs.

2. Key Factors in Level Meter Selection

2.1 Material Properties

Tank material characteristics such as density, viscosity, corrosiveness, conductivity, and volatility influence the choice of measurement principle:

- Low-density liquids: Standard float or rotary switches may fail to actuate; vibrating or radar level meters are more suitable.

- Corrosive liquids: Require corrosion-resistant probe materials (PTFE, PVDF, 316L stainless steel) and leak-proof design.

- High-viscosity or crystallizing liquids: Mechanical contact switches may stick; non-contact radar or guided wave radar is preferred.

2.2 Process Conditions

Temperature, pressure, agitation, and foam can affect measurement performance.

- High temperature/pressure: Use level meters rated for extreme conditions, considering probe expansion and electronics insulation.

- Agitation or flow: Liquid surface fluctuation may trigger frequent switching in floats or rotary devices; use filtered or delayed response meters.

- Foam or bubbles: Ultrasonic measurement may be impacted, while radar meters with signal processing can detect the true liquid surface.

2.3 Measurement Accuracy and Response

Applications differ in precision and response requirements:

- Precision process control: Continuous, high-accuracy measurement needed for reactors or tanks; guided wave radar or hydrostatic pressure meters are suitable.

- Overflow or dry-run protection: High-reliability point-level switches, such as vibrating forks or rotary switches, suffice.

2.4 Safety and Protection

Explosion-proof and leakage prevention are critical. Choose intrinsically safe (Ex ia), explosion-proof (Ex d), or increased safety (Ex e) meters according to tank area classification. IP protection ensures stable operation under dust, vapor, or rain.

2.5 Lifecycle Cost

Selection should consider purchase cost, installation, commissioning, maintenance, calibration, and replacement. Proper choice reduces operational downtime and maintenance expenditures.

3. Common Types of Tank Level Instruments

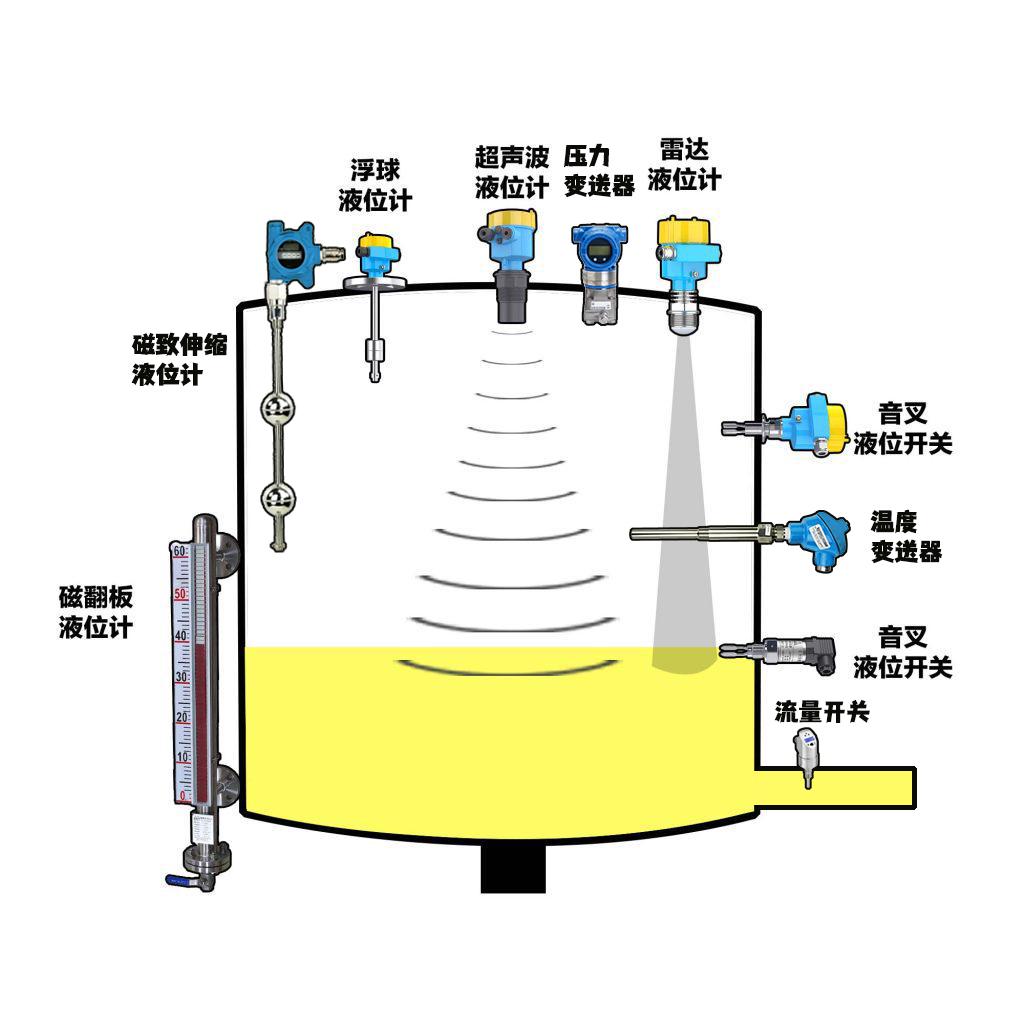

- Float Level Switch

Suitable for low-temperature, low-pressure, non-viscous liquids. Simple and inexpensive but unsuitable for high-viscosity, crystallizing, or foaming liquids. - Rotary Paddle (Rotary Vane) Switch

Ideal for slurry or solid-liquid mixtures. Robust and corrosion-resistant, suitable for medium to low-density materials. - Vibrating Fork Level Switch

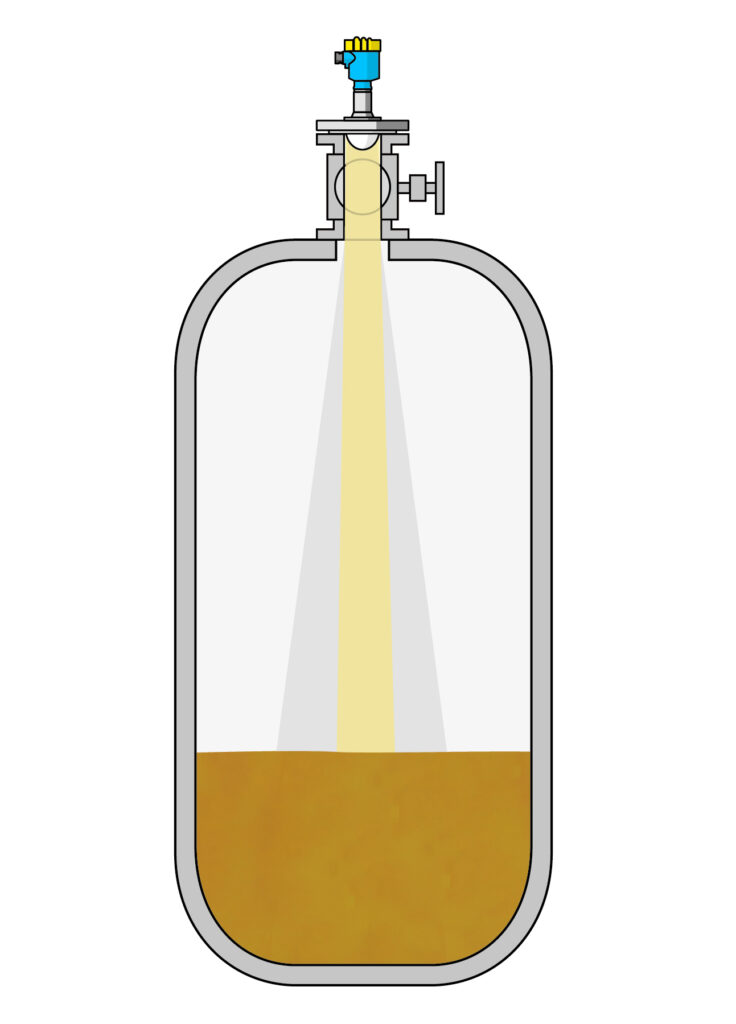

High sensitivity, can detect ultra-low density materials, foam, or powders. Low maintenance and rapid response. - Radar Level Meter (Non-contact / Guided Wave)

Handles high-temperature, high-pressure, foamy, or viscous liquids. Provides continuous, precise measurement and integrates with automation systems. - Ultrasonic Level Meter

Cost-effective for standard tanks, but may be influenced by vapor, foam, or obstacles. - Hydrostatic (Pressure) Level Meter

Calculates liquid level via pressure. Suitable for simple tanks with stable density; caution needed for high-temperature or crystallizing liquids.

4. Practical Guidelines for Selection

- Systematic Assessment: Evaluate tank material, liquid properties, process conditions, accuracy requirements, safety classification, and budget comprehensively.

- Redundancy and Safety: Critical tanks may use dual-level systems (switch + continuous measurement) for increased reliability.

- Digital and Remote Management: Modern meters support 4–20 mA, HART, Modbus, or wireless communication for remote monitoring, logging, and process optimization.

- Maintenance and Calibration Planning: Schedule regular inspections and calibrations based on liquid properties, environment, and precision needs to ensure long-term stability.

5. Engineering Value and Management Significance

Proper selection ensures long-term reliable and traceable data, reduces maintenance frequency, and supports continuous and safe operation. Accurate measurement enhances trade settlement, inventory management, and fine-tuned operations.

Incorrect selection can amplify measurement deviation, increase failure rates, and create hidden safety risks. In modern automated and intelligent facilities, level meter selection reflects overall system safety, production stability, and operational capability.

6. Conclusion

Tank level measurement is a foundation for production control, safety management, and economic operations in modern chemical and industrial plants. Selecting a level meter requires integrating material properties, process conditions, safety requirements, and lifecycle cost considerations.

Through systematic evaluation, proper installation, digital commissioning, and smart maintenance, tank level meters can provide accurate, reliable, and traceable measurements, ensuring production safety, process optimization, and operational efficiency.