Flange Sealing Surfaces in Industrial Piping: Gasket Matching for Reliable Seals

In piping systems, the type of flange sealing surface often determines the upper limit of the entire sealing system.

Many focus on flange material and pressure rating, but overlook sealing surface compatibility. Sealing surfaces are critical because they directly affect:

- Gasket compression capability

- Resistance to media corrosion

- Ease of disassembly and maintenance

- Leakage probability, especially in VOC pipelines

The flange sealing surface is essentially the “seat” of the sealing system. Even the best gasket cannot perform reliably if the seat design is poor.

1. Sealing Area, Gasket Hardness, and Surface Pressure

Generally:

- Large sealing area → lower unit pressure → softer gaskets are easier to compress

- Small sealing area → higher unit pressure → harder gaskets needed for high-pressure metal sealing

Soft materials can achieve sufficient compression under low pressure, while hard materials (especially metal gaskets) require higher pressure for effective plastic deformation.

Common flange trends:

- FF (Flat Face): largest sealing area → soft gaskets (rubber, fiber)

- RF (Raised Face): medium sealing area → semi-metal gaskets (graphite)

- RTJ (Ring-Type Joint): smallest sealing area → metal gaskets

These designs result from the combined considerations of thermal, mechanical, and material properties.

2. Common Sealing Surface Types

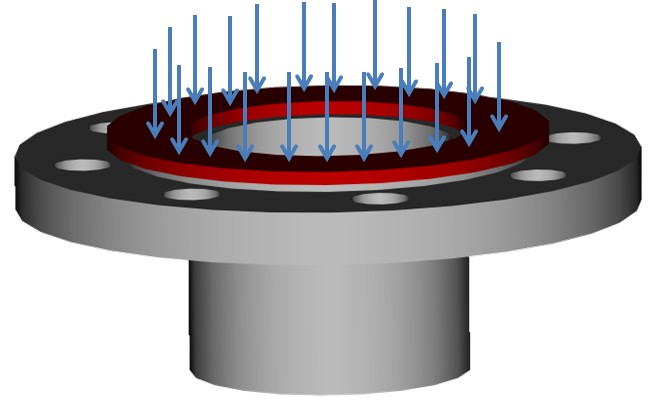

1. RF (Raised Face)

RF flanges feature a circular sealing surface raised above the bolt circle, forming an independent compression zone. High preloading allows a metal ring gasket to deform plastically into the flange groove, achieving metal-to-metal sealing.

- Smallest sealing area, highest surface pressure, hardest gasket (metal)

- Surface roughness (Ra 3.2–6.3 μm) creates micro-grooves for gasket embedding

- Sensitive to bolt preload; thermal cycling may reduce sealing stress

2. FF (Flat Face)

Flat face flanges protect brittle materials like cast iron. The sealing area spans the full flange face, and low surface pressure requires soft, deformable, and resilient gaskets.

- Large sealing area → low surface pressure → soft gasket mandatory

- Cannot mate with RF flanges of harder materials

- Suitable for low-pressure applications (125–250 ratings)

3. RTJ (Ring-Type Joint)

RTJ flanges are designed for high-pressure or high-temperature (>750°C) applications. The sealing relies on metal gaskets (R, RX, BX types) slightly softer than the flange to ensure gasket deformation forms the seal.

- Groove geometry (oval or octagonal) affects stress distribution

- BX type self-tightens with pressure, improving sealing at higher pressures

4. TG/MFM (Tongue & Groove / Male & Female)

These designs stabilize gasket position, preventing radial slip due to uneven bolt torque, vibration, or thermal expansion.

- TG: tongue-and-groove; strong positional constraint, ideal for soft gaskets

- MFM: male-and-female; wider contact area, more uniform stress distribution

5. LMF/LCF (Large Male-Female)

Used in pressure vessel connections, these flanges enlarge the contact surface for broader pressure distribution, enhancing reliability.

6. SJ Self-Energized Seal

Utilizes media pressure to increase sealing force; gaskets are plastically deformable metals. Common in cryogenic, high-temperature, or pulsating pressure systems.

3. Gasket and Surface Matching Logic

Sealing is not simply “sandwiching a gasket between flanges” but controlling material deformation under normal and shear forces. Core considerations:

- Compressibility: Ability to reach sealing state under pressure (RF, FF require high compression; RTJ requires plastic deformation)

- Resilience: Adapts to thermal expansion, creep, or relaxation; insufficient rebound leads to VOC leaks

- Creep relaxation: Long-term ability to maintain surface pressure; high temperature and soft gaskets increase creep

Conclusion

Sealing is not guesswork. Choosing the right flange surface reflects an engineer’s understanding of mechanics, materials, operating conditions, and risk. Selecting the correct sealing surface can improve system stability by an order of magnitude.

If process parameters (media, pressure, temperature, fluctuation range, flange standard) are provided, a tailored engineering sealing surface recommendation and risk assessment can be generated for design review or procurement decisions.