Working Principle and Applications of Fork-11 Tuning Fork Level Switch

Tuning fork level switches are the most common type of vibrating level switch. Due to their simple structure, strong adaptability, maintenance-free operation, and no need for calibration, they are widely used across chemical, petrochemical, light industry, environmental, metallurgical, construction, food, and other sectors. Whether monitoring solid granules, powders, or ultra-low-density solids, tuning fork level switches provide reliable level detection and deliver accurate signals to automation control systems. This article systematically analyzes the working principle, core technology, performance characteristics, and typical applications of tuning fork level switches.

1. Working Principle of Tuning Fork Level Switches

The core component of a standard tuning fork level switch is a piezoelectric ceramic element. The switch uses the piezoelectric element to drive the fork into vibration. When the fork is free from contact, it vibrates at its resonant frequency with stable amplitude. Once material comes into contact with the fork, the vibration amplitude decreases sharply, and both frequency and phase experience significant changes. These changes are detected by the internal electronics and converted into a switch signal output.

For example, the Fork-11 tuning fork level switch produced by Shenzhen Jiwei Automations Ltd uses a classic tuning fork design with piezoelectric devices to drive and detect fork vibrations. The operation process is as follows:

- Free Vibration State: When the fork is not in contact with material, it vibrates at the designed resonant frequency, generating a stable electrical signal.

- Material Contact State: Upon contact with the material surface, the vibration amplitude decreases significantly, and the output signal from the piezoelectric element reduces accordingly.

- Signal Analysis and Switch Output: The internal intelligent circuit continuously monitors signal changes. By applying a specific algorithm, it determines whether the fork has contacted material and outputs a switch signal.

- Sensitivity Enhancement: By optimizing the fork structure and increasing fork surface area, Fork-11 can detect ultra-light materials with densities as low as 0.008 g/cm³, such as foam particles or light powders.

This principle, based on the coupling of the piezoelectric effect and mechanical vibration, provides rapid response, strong anti-interference capability, and long-term stable operation under high-temperature, high-humidity, or dusty environments.

2. Piezoelectric Element and Electronics Design

The reliability of a tuning fork level switch depends on the coordination between the piezoelectric element and the electronic circuit. Fork-11 adopts high-stability piezoelectric ceramics with the following characteristics:

- Temperature Adaptability: Maintains stable vibration frequency from -40 to +400 °C, suitable for extreme industrial conditions.

- Vibration Resistance: Strong resistance to mechanical shocks and continuous vibration, unaffected by external disturbances.

- Long-Term Stability: Electrical properties degrade slowly, ensuring consistent switch output over time.

On the electronics side, Fork-11 features an intelligent signal processing unit capable of:

- High-frequency signal filtering to eliminate environmental noise.

- Automatic amplitude threshold determination to improve detection accuracy.

- Tolerance to short-term amplitude fluctuations, preventing false triggering.

- Selectable normally open (NO) or normally closed (NC) output modes for easy integration with automation systems.

The combination of hardware and software ensures high reliability under complex operating conditions.

3. Application Scenarios

Tuning fork level switches have broad applications, covering various solid and powder materials.

3.1 Chemical and Petrochemical Industry

In chemical facilities, Fork-11 is widely used for monitoring levels in silos, pipelines, and reactors. Its high-temperature and corrosion-resistant properties allow long-term measurement of resins, granular catalysts, powders, and chemical substances. In explosive environments, intrinsically safe (Ex ia) versions can be applied to ensure personnel and equipment safety.

3.2 Food and Light Industry

During the processing of candies, grains, coffee beans, chili powder, and other food materials, level monitoring prevents spillage and conveyor blockage while providing accurate signals to automated feeding systems. Fork-11’s non-contact detection and easy-to-clean design meet stringent hygiene requirements of the food industry.

3.3 Environmental and Water Treatment

In wastewater treatment or sludge storage, tuning fork level switches detect settled solids and suspended particles. Their anti-corrosion and turbidity-resistant design ensures long-term stable operation, reducing maintenance frequency.

3.4 Construction and Metallurgy

For bulk materials such as cement, ore, and fly ash, Fork-11 effectively monitors silo levels, preventing overloading and unplanned shutdowns. Adjustable sensitivity allows reliable operation even in high-dust or irregular particle environments.

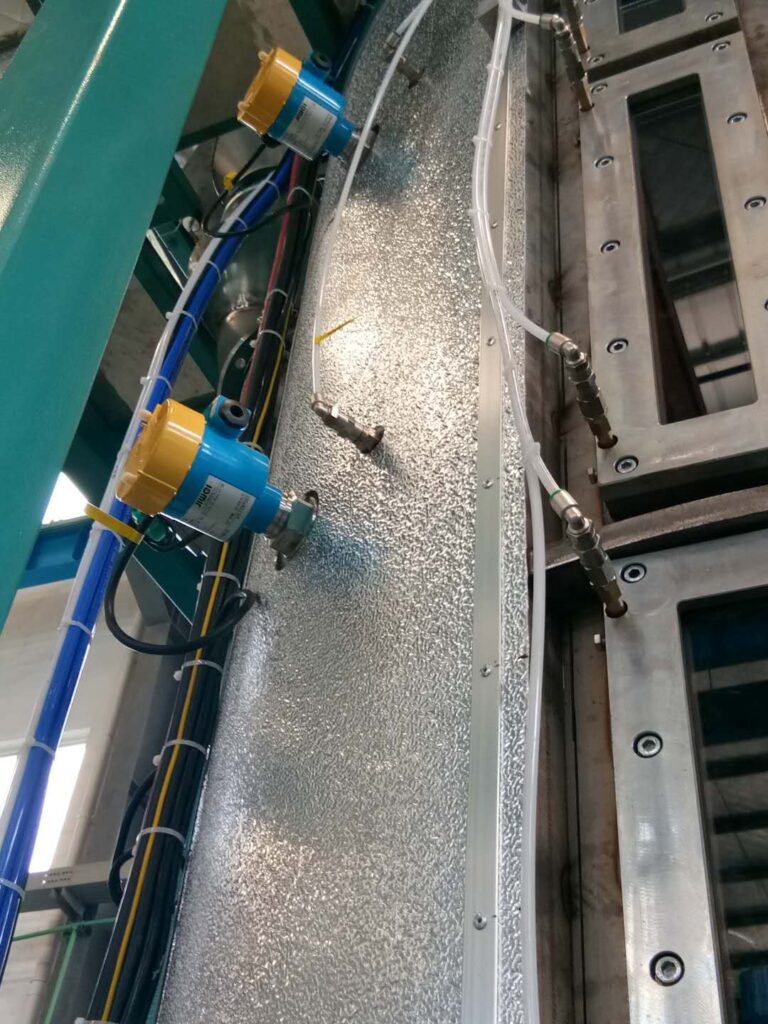

4. Installation and Commissioning

Tuning fork level switches offer flexible installation options and can be mounted at the top, side, or in pipelines depending on the vessel shape. A slightly downward installation angle is generally recommended to ensure full fork contact with material while avoiding accumulation. Fork-11 supports straight-thread or flange connections for easy replacement and maintenance.

Regarding commissioning, Fork-11 requires almost no manual adjustment. Its internal intelligent circuitry automatically sets switching thresholds based on material properties. Additionally, parameters and status can be monitored and configured via visual handheld devices or mobile applications, significantly simplifying field operations.

5. Performance Optimization and Engineering Value

- High Sensitivity: Capable of detecting ultra-light materials and low-density particles, expanding application scope.

- Anti-Interference Capability: Built-in filtering and delay algorithms reduce the effects of vibration, noise, and airflow.

- High Temperature and Humidity Resistance: Optimized piezoelectric elements and fork materials ensure reliable operation under harsh conditions.

- Low Maintenance: Non-contact measurement reduces wear and cleaning frequency.

- Safety and Reliability: Can interface with automation systems to provide real-time safety signals.

6. Conclusion

Tuning fork level switches are favored for their simple principle, strong adaptability, low maintenance cost, and fast response. Fork-11 combines piezoelectric driving with intelligent electronic circuitry, enabling detection of both high-density solids and ultra-light or low-density materials. Proper installation and commissioning ensure long-term stable operation, providing reliable level signals for automation systems and safeguarding production safety and efficiency.

In applications such as material transport, silo monitoring, and pipeline detection, tuning fork level switches have become a key tool for production control and process optimization. When integrated with digital commissioning platforms and engineering experience, their value in industrial automation continues to grow.