Jiwei Fork-11 Vibrating Fork Level Switch in Foam Pre-Expansion and Molding Machines

1. Industry Background: From EPS to EPP, the Rigid Demand for Ultra-Low-Density Level Monitoring in the Foam Industry

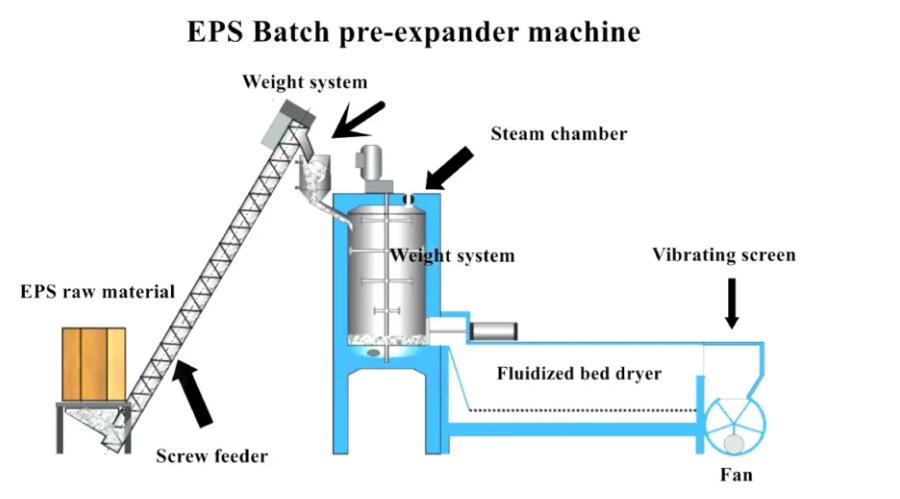

In the upstream equipment systems of the foam industry, the two most critical units are the foam pre-expander (Pre-expander) and the foam molding machine (Molding Machine). Whether producing EPS (expandable polystyrene), EPP (expanded polypropylene), or EPO (expanded polyolefin), the production process always relies on precise monitoring of material density, expansion ratio, and level intervals.

Compared with chemical powders, metal particles, or conventional plastic granules, foam materials present three prominent characteristics:

- Extremely low density (Density < 0.01 g/cm³)

- EPS pre-expansion density can reach as low as 0.008 g/cm³ (8 kg/m³).

- High fluffiness, weak flowability, and unstable stacking make traditional mechanical, volumetric, or even some capacitive level devices unreliable.

- Irregular and easily disturbed material surface

- Airflow, steam, vibration, suction, and exhaust systems create irregular fluctuations in the material surface, causing many sensors to misfire or fail to trigger.

- Complex operating conditions, varying by machine type

- Pre-expanders (primary expansion): lowest density, strongest airflow, high disturbance

- Molding machines (cavity feeding): require fast response and consistent operation

- Fluidized drying sections: high wind speed, suspended dust and particles

- Large hoppers and transfer containers: high drop distances and varying volumes

Under these conditions, the industry commonly uses:

- VEGA tuning fork switches

- Taiwan FineTek

- Germany UWT

- Several domestic capacitive or rotary paddle devices

However, in ultra-low-density scenarios, these solutions often struggle to operate stably. Foam equipment manufacturers rely heavily on level switches because even a single misjudgment can result in density deviations in the first or second expansion, leading to an entire batch failing quality standards.

2. Typical Level Challenges in Foam Pre-Expanders

Pre-expanders are the most sensitive and critical stage in the foam production process. Any abnormality in feeding, expansion, discharge, or drying directly affects final product density and stability. In practice, level detection faces multiple challenges:

- Extremely low particle density prevents tuning forks from gaining sufficient damping, causing failure to trigger.

- Fluidizing air or steam can make the material surface appear higher, causing false triggers.

- Static electricity causes particles to adhere to the fork, destabilizing signals.

- Significant temperature gradients (40–95°C) in the pre-expansion zone can affect the performance of lower-quality devices.

- High moisture content and humidity interfere strongly with capacitive measurement.

Due to these complex factors, many manufacturers have long considered VEGA tuning fork switches as a “high-end standard” to ensure reliable level detection in lightweight and easily disturbed foam environments.

However, as production increasingly emphasizes density consistency, batch stability, and continuous throughput control, VEGA has revealed new usage challenges in some factories: high cost, long supply lead times during expansion or equipment updates, and slower after-sales support from overseas brands, which cannot meet the foam industry’s rapid iteration and high-intensity operation needs. These factors have driven manufacturers to seek more cost-effective, responsive, and locally adaptable alternatives.

3. Jiwei Fork-11: Why It Handles Extreme Foam Densities

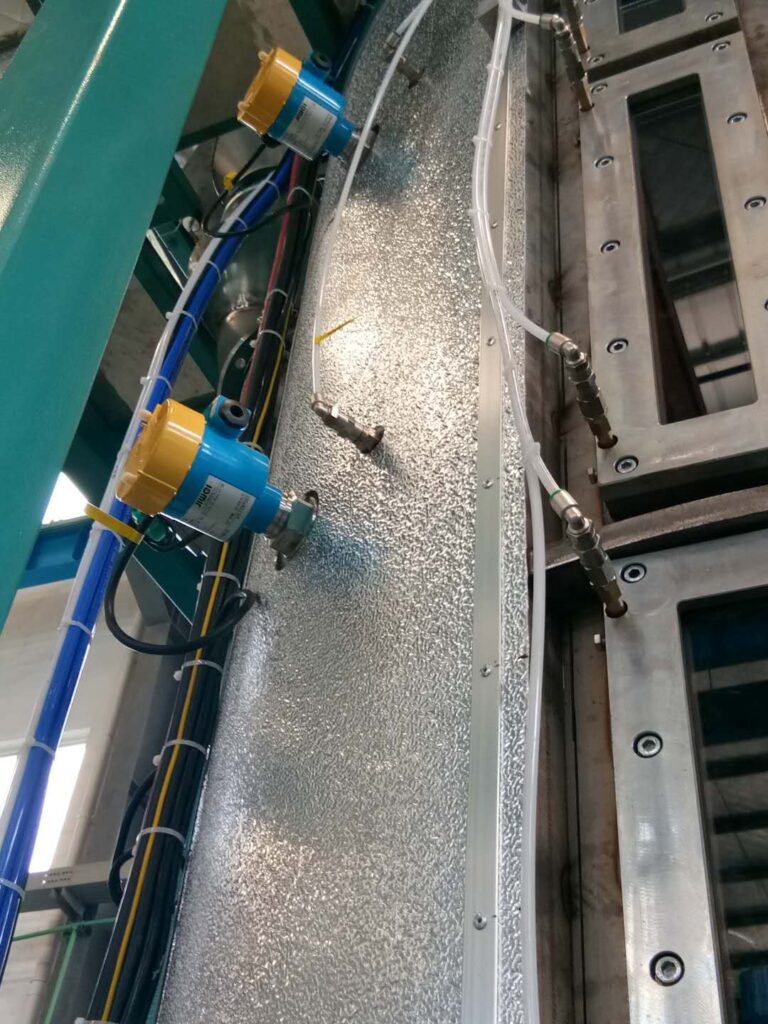

Jiwei Automation’s Fork-11 series vibrating fork level switches are fundamentally optimized for lightweight material applications. Its design encompasses fork geometry, material rigidity, vibration frequency matching, and driving energy output, allowing it to maintain stable triggering in ultra-low-density, high-fluidization, and fluctuating heat/humidity conditions of foam pre-expansion and molding.

Compared with traditional tuning forks, Fork-11’s vibration characteristics are better suited to lightweight particles. Its natural frequency and damping response have been extensively tested to ensure the fork can detect slight contact-induced vibration changes. This guarantees reliable operation even at 0.008 g/cm³ ultra-low-density conditions. Thanks to this deep structural optimization, Fork-11 can maintain long-term stable operation under strong steam, airflow disturbance, high temperature differences, and high moisture—making it a mature solution widely replacing VEGA in the industry.

1. Fork Geometry: High Sensitivity for Lightweight Materials

- Wide fork walls

- Thin fork body

- Precisely tuned vibration frequency

Purpose: Generate sufficient interference from materials to ensure reliable switch operation at ultra-low density. Traditional forks with thick bodies or standard designs often fail to provide enough damping at 0.008 g/cm³.

2. Vibration Frequency and Excitation Amplitude: Key to Ultra-Low-Density Triggering

- Optimized frequency for low-density media

- Resonance amplitude suitable for small mass loading

- Switch hysteresis designed for material surface disturbances

If frequency is too high, light materials cannot generate sufficient damping; too low, wind disturbance may affect operation. Fork-11 hits the ideal range for foam industry characteristics.

3. Internal Drive and Detection Module: High Sensitivity to Micro Load

Fork-11’s drive circuit uses high-sensitivity oscillation detection, triggering without requiring large material loads. This enables reliable operation at densities as low as 0.008 g/cm³, comparable or superior to VEGA. Few manufacturers in the industry can achieve this.

4. Comparison with VEGA: Why More Customers Prefer Fork-11

1. Operational Consistency: Adapted to Rapid Feeding/Discharge

In pre-expanders, material levels change rapidly, especially with strong suction airflow and continuous material inflow/outflow. Fork-11 demonstrates high consistency:

- Rising levels → rapid triggering

- Falling levels → timely reset

- No lag, adhesion, or hysteresis

Many manufacturers immediately notice a more responsive and stable level detection after switching to Fork-11, improving production rhythm and reducing material waste and operational errors.

2. Longevity and Maintenance: Core Reason for 10-Year Continuous Use

Fork-11 has numerous successful cases in the foam industry:

- Many clients have continuously used it for over 10 years without changing brands

- Advantages include high reliability of piezo ceramics, fatigue-resistant fork body, stable operation in long-term high temperature/humidity, non-sticking structure, and no recalibration required

- Continuous steam, moisture, static, and manual pressure in foam lines often damage other devices; Fork-11 has proven long-term durability

3. Cost and Supply: VEGA’s Limitations Are Mainly Cost and Lead Time

In the foam industry, equipment export volume is high, making total cost control critical. VEGA challenges include high unit price, long lead times for bulk supply, expensive spare parts, and inconsistent global availability. Fork-11 advantages:

- More controllable price

- Stable bulk delivery capability

- Quick on-site replacement without parameter adjustment

- Direct replacement without changing installation

As a result, many equipment manufacturers have shifted their “default configuration” from VEGA to Fork-11 to improve cost efficiency and production continuity.