Winter Lifesaver for Instrument Piping: Starting with Electric Heat Tracing

Why Winter Makes Factories Especially Sensitive to “Heat Tracing”

Every winter, in northern factories, the first concern is often not the large equipment but the instrumentation electric heat tracing and piping throughout the plant. Compressed air lines can freeze, differential pressure chambers may become inaccurate due to ice, level measurement lines can clog with ice, and even ordinary impulse lines may freeze with sudden temperature drops. A single instrument reading failure can trigger chain reactions that halt an entire production line.

During particularly cold years, many plants have experienced dozens of simultaneous alarms just because temperatures dropped by 10°C. Engineers scramble to respond using electric blankets, heat guns, or temporary heaters, but such solutions are unsustainable, unsafe, and cannot guarantee long-term reliability.

In fact, instruments are just one of the most sensitive points for winter heating. Valves, flanges, pipelines, and storage tanks also require protection. To keep these systems stable in low temperatures, factories need a solution that provides continuous, automatic heat — the often-overlooked “unsung hero” of winter operations: the Electric Heat Tracing System.

Many people assume heat tracing is complicated, but its core idea is simple: add heat to pipes, valves, and tanks to prevent freezing, thickening, or solidification of fluids. However, when implemented in real engineering practice, it involves numerous technical details.

What Is a Electric Heat Tracing System?

Factories in cold climates are most concerned not about equipment damage, but about ordinary pipes freezing. Frozen or viscous liquids can stop flow, rupture valves, overload pumps, or cause instruments to fail, potentially shutting down the entire system. To prevent these risks, heat tracing systems maintain temperature in pipes, valves, tanks, and instrumentation, keeping fluids flowing and preventing freezing or crystallization. Think of it as giving industrial equipment a “self-heating winter coat,” ensuring continuity and safety of production.

Why Heat Tracing Is Important

Many common fluids change properties when cooled:

- Water can freeze and rupture pipes.

- Diesel and crude oil become viscous and difficult to pump.

- Certain chemicals crystallize at specific temperatures.

- Other media may fail to meet process requirements when cold.

If any part of the system drops below the required temperature, it can trigger chain reactions, causing production stoppages or safety incidents. A heat tracing system maintains sufficient temperature so that pipelines stay flowing, movable, and unclogged — an essential infrastructure in northern chemical plants, power plants, food processing, and various fluid transport systems.

How Heat Tracing Works

Heat tracing generally comes in three forms: electric, steam, or hot water/thermal oil tracing, with electric tracing being the most widely used. Electric systems are flexible, precise, and do not require a large steam network, making them ideal for modern, highly controlled factories.

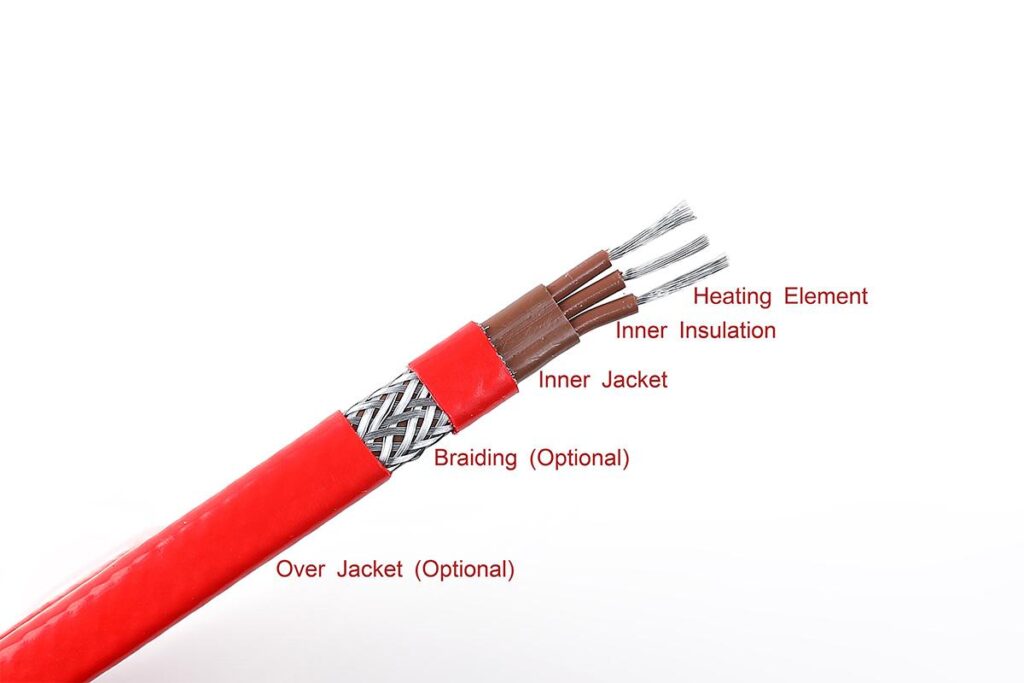

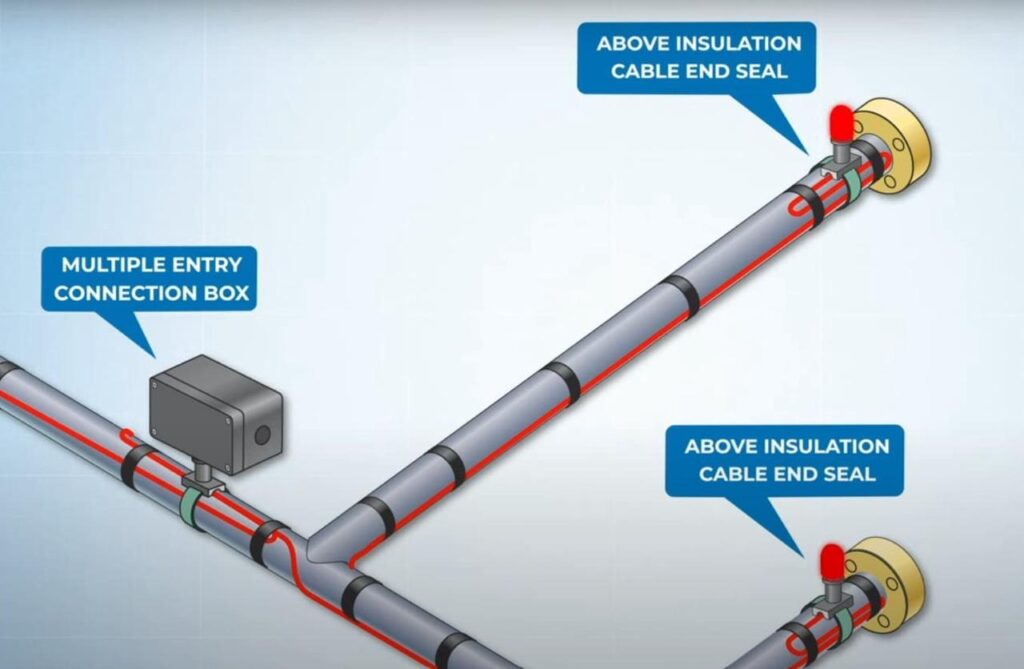

Electric heat tracing works by running a heating cable along the length of pipes or containers to prevent freezing or maintain a set temperature. High-temperature heat tracing cables are attached directly to the pipe, powered via a simple connection box. For precise control, digital thermostats monitor and adjust the temperature automatically.

Branch connections or pipe joints can be covered using multi-port junction boxes to extend heat tracing coverage. End seals prevent moisture ingress and physical damage. All cables are then insulated to minimize heat loss, and warning labels indicate that heating elements are present and surfaces may be hot.

Common Types of Electric Heat Tracing

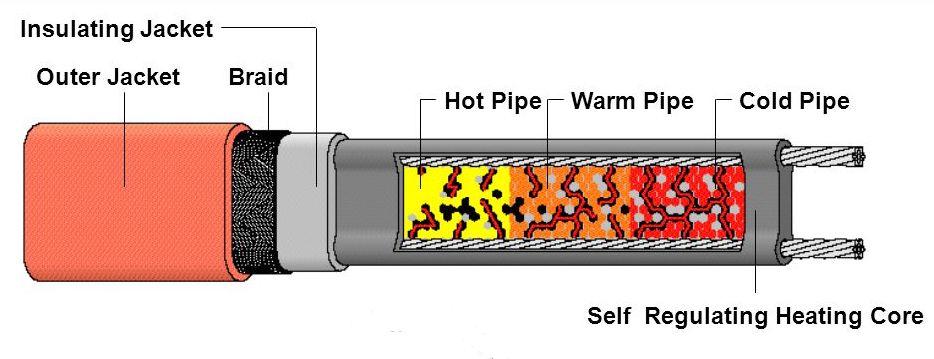

- Self-limiting heat tracing cable

- Changes resistance with temperature: increases heat when cold, reduces heat when hot.

- Safe, flexible, long-lasting, suitable for freeze protection and low-temperature applications.

- Constant wattage heat tracing cable

- Produces stable, continuous heat.

- Suitable for long-distance, medium-temperature heat tracing, typically used with a thermostat for safety.

- Mineral-insulated (MI) cable

- Can operate stably at 200–600°C, resistant to fire, corrosion, and radiation.

- Ideal for high-temperature chemical processes, oil, sulfur systems, and nuclear plants. Requires professional installation but extremely reliable with long lifespan (~20 years).

Components of a Complete Heat Tracing System

A heat tracing system is more than just the cable. It includes:

- Power connections, junction boxes, or explosion-proof boxes

- Temperature control devices

- Cable supports and fastening materials

- Insulation layers

Cables provide heat, insulation retains it. A failure in either compromises system performance. Many heat tracing issues arise from improper installation, inadequate insulation, or faulty temperature control, rather than cable defects.

How Heat Tracing Systems Are Designed

- Determine target temperature

- Example: Water ≥ 5–10°C, Diesel ≥ 20°C, Crude Oil 60–80°C, Resins/Fats 100°C.

- Consider lowest ambient temperature

- Calculate heat loss based on pipe diameter, insulation thickness, material, wind speed, and medium temperature.

- Select cable power based on heat loss

- Freeze protection: 10–20 W/m

- Medium temperature: 20–40 W/m

- Process heating: 40–60 W/m

- High-temperature MI cable: 80–200 W/m

- Decide installation method

- Single run, spiral wrap, parallel runs. Extra loops for valves, flanges, and pumps.

- Temperature control and electrical design

- Simple: mechanical thermostat

- Precise: PT100 sensors + control cabinet

- Hazardous areas: explosion-proof

- Long distance: account for voltage drop

- Installation and commissioning

- Common errors: damaged insulation, poorly secured cables, compressed or bent cables, insufficient wrapping at valves.

- Verification includes insulation resistance, current measurements, and temperature response testing.

Common Issues on Site

Most failures are not the cables themselves but:

- Damaged or missing insulation

- Faulty thermostats

- Cables compressed, bent, or improperly installed

- Voltage drop on long circuits

- Insufficient coverage at valves or flanges

Heat tracing is a system-level solution requiring careful attention to electrical, mechanical, and insulation aspects from design through commissioning.

Summary

For beginners, understanding heat tracing involves:

- Knowing medium properties

- Distinguishing cable types

- Understanding heat loss principles

- Familiarity with installation methods

- Mastering temperature control systems

Heat tracing may seem simple, but it is critical for stable winter operations, ensuring fluids remain flowing and processes continue uninterrupted. Understanding these principles enhances engineers’ professional skills and appreciation of the underlying infrastructure supporting complex industrial systems.