PLC Control Systems: A Comprehensive Guide

With the rapid development of Industry 4.0, smart manufacturing, and digital twin technologies, the PLC (Programmable Logic Controller) is no longer merely a “logic control device.” It has evolved into a core control unit capable of data processing, communication, and intelligent decision-making, effectively serving as the “brain” of modern automation systems. PLCs not only govern production line operations but also impact overall system safety, scalability, and intelligence. This article provides a professional engineer’s perspective, systematically covering ten core knowledge areas of PLCs to help you advance from “using PLCs” to “understanding system architecture.”

1. PLC Working Principles and Intelligent Evolution: From Control to Computation

PLC is essentially a specialized industrial computer that performs continuous monitoring and control through cyclic scanning (Scan Cycle). Each cycle consists of three main stages:

- Input Scan: Collecting signals from sensors, buttons, and other field devices;

- Program Execution: Performing logic calculations and decision-making based on the programmed instructions;

- Output Update: Sending commands to actuators such as relays, motors, and valves.

This scanning mechanism allows millisecond-level responsiveness, ensuring real-time and stable control. Modern PLCs are evolving into Smart PLCs, integrating AI algorithms, remote diagnostics, and cloud communication, making them key nodes in edge computing and Industrial IoT (IIoT) architectures.

2. System Architecture: PLC Modules and Engineering Considerations

A standard PLC system is composed of multiple functional modules, each crucial for overall stability:

- CPU Module: Executes logic operations, data communication, and system decisions;

- Input Modules (DI/AI): Acquire digital and analog signals;

- Output Modules (DO/AO): Control motors, valves, indicator lights, etc.;

- Communication Modules: Enable data exchange with HMI, drives, and SCADA systems;

- Power Supply Module: Provides stable voltage, filtering interference and surges.

In modern plants, PLCs often form distributed control systems (DCS) through remote I/O and fieldbus networks. Design recommendations: Separate strong and weak current circuits, use shielded cables for I/O, and apply single-point grounding to minimize electromagnetic interference and false triggering.

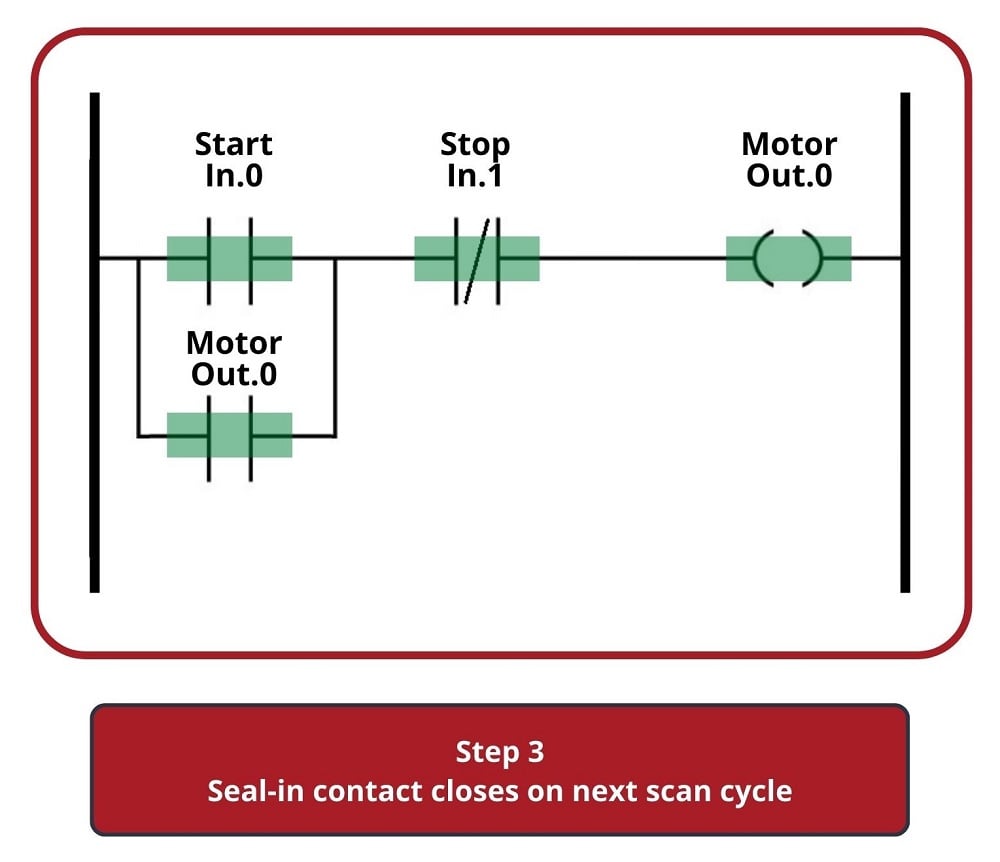

3. PLC Programming Languages: Five Logic Expressions

IEC 61131-3 defines five PLC programming languages, each reflecting a distinct logic thinking mode:

- Ladder Diagram (LD): Intuitive relay-based logic, suitable for electricians;

- Function Block Diagram (FBD): Modular signal processing, ideal for process control;

- Instruction List (IL): Low-level, assembly-like commands (gradually replaced by ST);

- Structured Text (ST): High-level syntax, flexible for complex algorithms;

- Sequential Function Chart (SFC): Excellent for multi-stage processes and sequential control.

In practice, hybrid programming is common. Main logic often uses LD for visualization and debugging, algorithmic or data-intensive parts use ST, and functional modules like PID loops utilize FBD. Skilled engineers understand task scheduling, variable sharing, and cross-language logic, enabling system-level control rather than just programming execution.

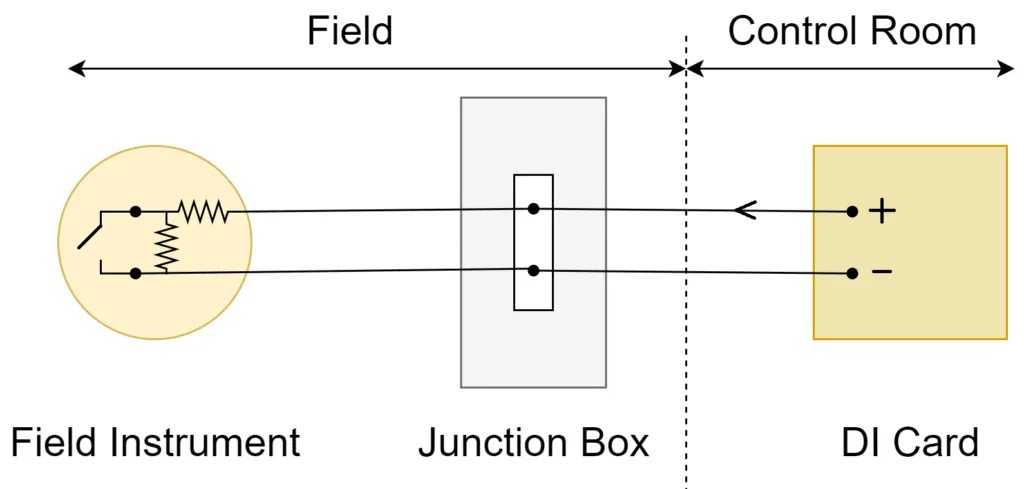

4. I/O System Design: Signal Wiring and Isolation Protection

The I/O modules serve as the PLC’s connection to the physical world. Proper wiring is critical:

- Digital I/O (DI/DO): Monitors switch states;

- Analog I/O (AI/AO): Processes continuous signals like temperature, pressure, and flow;

- Signal Isolation: Optical couplers, filters, and surge suppressors improve interference resistance;

- Grounding and Shielding: Single-point grounding and layered shielding prevent loop interference.

Improper grounding is a common cause of communication failure or false alarms. Separating signal ground from protective ground is essential, particularly in high-speed production lines.

5. Communication Protocols and Industrial Networks

Modern PLCs operate within complex industrial networks:

- Modbus RTU/TCP: Open, cross-brand compatible;

- Profibus/Profinet: Siemens ecosystem standard;

- EtherNet/IP: Suitable for high-speed real-time control;

- CANopen/DeviceNet: Common for robotics and motion control;

- OPC UA: Supports data modeling and cloud connectivity, critical for IIoT.

PLCs are now central to digital factories, supporting end-to-end data flow from local control to cloud integration.

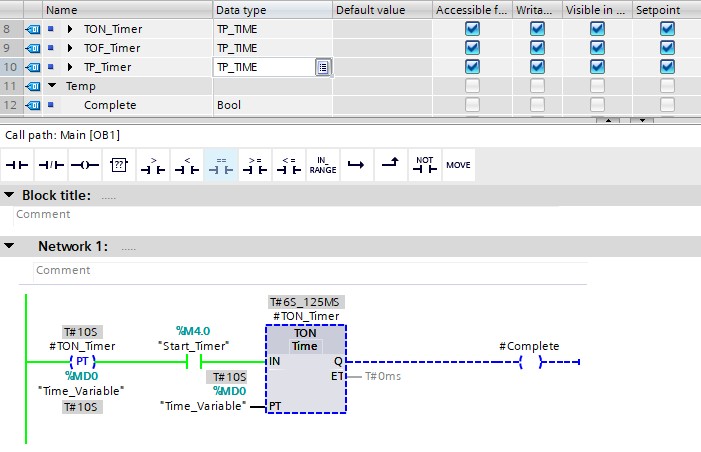

6. Timers and Counters: Simple Tools, Powerful Logic

PLC timers (TON, TOF, TP) and counters (CTU, CTD, CTUD) form the foundation of logic control. They enable:

- Production pacing and batch switching;

- Automatic start/stop logic;

- Real-time monitoring with interrupt tasks for millisecond-level response.

For example, in high-speed packaging lines, CTU counters manage batch transitions and process timing, enabling fully automated operations.

7. PLC Fault Diagnosis and Maintenance Thinking

True PLC experts go beyond programming—they master system diagnostics. Effective troubleshooting requires analyzing hardware, software, and communication layers. Common steps include:

- Check CPU and I/O module indicator lights;

- Review the diagnostic buffer for error codes and timestamps;

- Monitor variables online to ensure logic execution;

- Use Force functionality to test I/O circuits;

- Inspect communication lines, terminals, and grounding for hidden faults.

Platforms like Siemens TIA Portal and Schneider EcoStruxure offer trend analysis, visualizing signal fluctuations and helping locate faults quickly. Mature engineers leverage these tools for predictive maintenance rather than reactive repairs.

8. Program Optimization and Real-Time Management

Optimizing PLC programs improves efficiency and stability:

- Minimize nested logic and redundant calls;

- Prioritize tasks (main, cyclic, interrupt) appropriately;

- Control scan cycles to avoid delay accumulation;

- Use local variables instead of global ones;

- Implement watchdogs and timeout protections.

For instance, optimizing a filling line reduced scan cycles from 50ms to 15ms, doubling response speed.

9. Safety Control and Emergency Measures

Safety is paramount. PLC systems must follow IEC61508 and ISO13849 standards, incorporating:

- Hardware redundancy: emergency stops, safety relays, dual-channel inputs;

- Software logic: interlocks, fail-safe designs;

- Emergency mechanisms: power-loss retention, remote alarms, self-tests.

Example: In automotive welding lines, PLCs immediately cut off robot drives upon communication loss, achieving SIL2 safety shutdown.

10. Standardization and Future Trends

Standards guide system-level design:

- IEC61131-3: Programming languages and execution models;

- IEC61508 / ISO13849: Functional safety frameworks;

- IEC62443: Industrial cybersecurity;

- OPC UA / MQTT: Integration with cloud platforms.

Future PLCs will merge with AI algorithms, digital twins, and edge computing, enabling predictive maintenance, self-learning, and collaborative optimization.

Conclusion: From Control Logic to System Intelligence

Mastering the ten core PLC knowledge areas means more than writing stable programs—it represents a system-level mindset. A skilled automation engineer integrates PLCs with field devices, processes, networks, and safety standards to build efficient, maintainable, and scalable smart systems.

Understanding physical processes, signal-response relationships, communication architectures, and safety compliance transforms the role from “electrical engineer” to “automation system architect.”

In the future, manufacturing competitiveness will hinge less on equipment size and more on system intelligence, integration flexibility, and data utilization. Engineers with holistic PLC understanding will lead the wave of smart manufacturing and digital twin innovation.