Double-Rod Vibrating Rod Level Switches: High-Sensitivity, Reliable Solid and Powder Level Detection

In modern industrial production, stable and reliable level measurement is a fundamental requirement to ensure continuous operation and safe production. Especially in industries where powders and granular materials are widely used—such as chemical, power, building materials, food, and metallurgy—level switches not only affect production efficiency but also directly impact equipment safety and maintenance costs.

Vibrating rod level switches, as a common point-level detection instrument, are increasingly adopted by enterprises due to their simple structure, high reliability, and strong adaptability. Based on probe structure, vibrating rod level switches are mainly divided into single-rod and double-rod types. Compared with single-rod designs, double-rod vibrating rod level switches demonstrate significant advantages in sensitivity, reliability, and adaptability to complex working conditions.

So, what exactly are the characteristics of double-rod vibrating rod level switches? Why do they stand out among numerous solid-level measurement solutions? This article provides a systematic analysis from multiple dimensions, including working principle, performance advantages, applicable conditions, and practical value.

1. Basic Working Principle of Vibrating Rod Level Switches

To understand the advantages of double-rod vibrating rod level switches, it is essential to understand the core logic of vibration-based level detection technology.

Vibrating rod level switches typically use piezoelectric devices as both driving and detection components. When the instrument is powered on, the piezoelectric element drives the probe to generate stable vibration while simultaneously monitoring changes in vibration status. Once the vibration characteristics change, the electronic module outputs a switch signal to achieve level control or alarm functions.

However, single-rod and double-rod structures differ significantly in their vibration response mechanisms.

2. Differences Between Single-Rod and Double-Rod Vibrating Rod Level Switches

1. Single-Rod Vibrating Rod Level Switches

Single-rod level switches operate on a “resonance” principle similar to a tuning fork. Only when the probe is completely surrounded by the material does the vibration damping increase significantly, causing amplitude reduction. The system detects this change and outputs a signal. This mechanism results in:

- High requirements for contact area

- Limited sensitivity to low-density materials

- Slow response under partial contact or uneven loading

Therefore, in complex conditions, detection delays may occur.

Additionally, some single-rod level switches on the market are prone to breakage under mechanical impact.

2. Double-Rod Vibrating Rod Level Switches

Double-rod vibrating rod level switches adopt a different structural design. Once the probe contacts the measured medium, the vibration amplitude or frequency changes significantly, and the piezoelectric detector outputs a synchronous signal drop. The smart circuitry then analyzes the signal and outputs a stable switching signal. Key advantages include:

- Immediate response upon contact

- Higher sensitivity

- Lower false detection rate

- Greater reliability

From an engineering perspective, this design reduces dependence on “complete coverage,” ensuring more stable performance in real industrial environments.

3. Core Features of Double-Rod Vibrating Rod Level Switches

1. Double-Rod Probe Structure for Wider Applicability

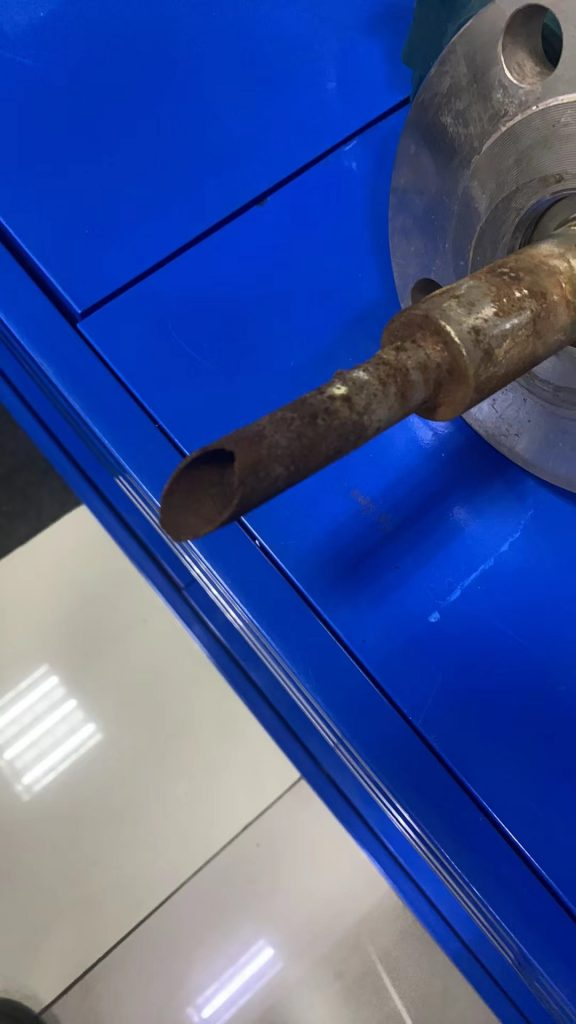

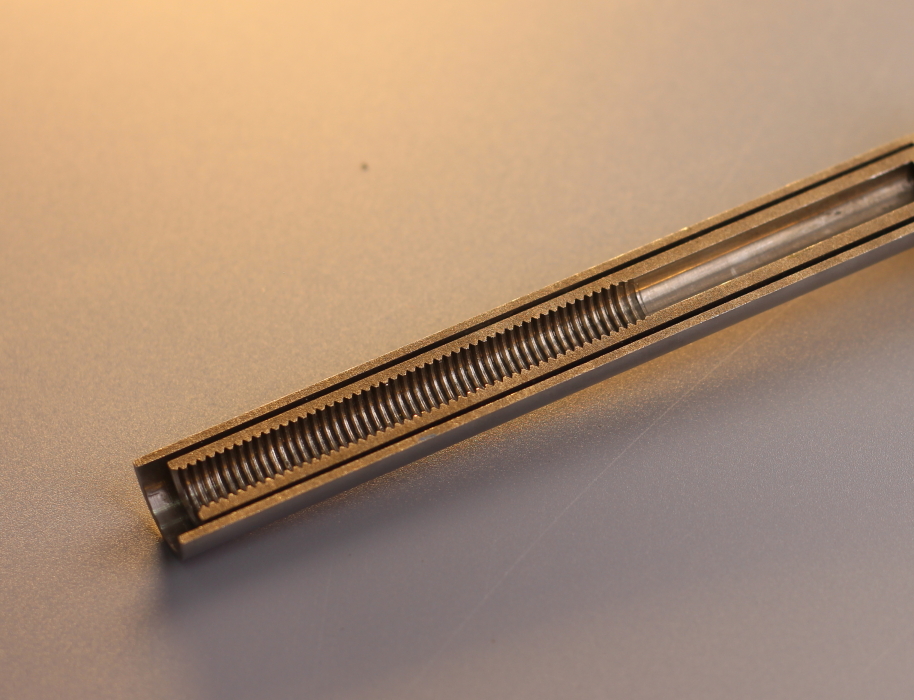

Shenzhen Jiwei’s double-rod vibrating rod level switches use a patented cross-sectional design, providing robust structure and enhanced impact resistance.

The double-rod probe design significantly improves vibration response efficiency, generating a clear and identifiable signal change immediately upon contact with the material, enabling more reliable level detection. Thanks to this structural advantage, the instrument can be widely applied in various solid material measurement scenarios, including PVC particles, sodium hydroxide, lime, sand, soil, coal, industrial dust, as well as sugar, grains, and beans. It maintains stable detection performance across different particle sizes and bulk characteristics. Whether handling fine flowing powders or larger granular materials, it effectively reduces false and missed alarms, ensuring continuous production stability.

At the same time, detecting sediments in water has long been a challenging condition in level measurement. Such media often exist in solid-liquid mixtures, with sediment layers that may be loose or uneven and can be disturbed by water flow, resulting in unclear material interfaces. When the probe is only partially in contact, some traditional detection methods cannot respond in time. The double-rod structure is more sensitive to contact changes; even when the probe just touches the sediment layer, it generates a clear vibration change and outputs a stable signal, improving measurement certainty. Additionally, its structure provides anti-adhesion capability, reducing interference from long-term particle accumulation, enabling stable operation in sedimentation tanks, wastewater treatment systems, and storage tanks containing solid-laden water.

For deep containers such as large silos or tall hoppers, rope-type (flexible cable) structures further extend the application range. These products use flexible cable connections, with extended lengths up to 20 meters, allowing precise detection points at critical levels, significantly expanding the instrument’s application depth and range. Rope-type double-rod probes are also suitable for detecting water sediments, enabling direct extension of the probe to the sediment layer for stable detection. They demonstrate strong adaptability and long-term reliability across granular solids, powder media, and challenging sediment conditions.

2. High Sensitivity for Ultra-Low Density Materials

Double-rod vibrating rod level switches employ a high-sensitivity vibration detection mechanism. Piezoelectric devices continuously monitor the probe’s vibration status. Once the probe contacts the medium, the system quickly captures subtle amplitude and frequency changes, which are analyzed in real time by intelligent circuitry to output a stable and reliable switching signal. Based on this detection principle, the instrument can identify media with densities as low as 0.02 g/cm³, a significant advantage in vibration-type level products.

This low-density detection capability allows reliable operation even for lightweight, loose, or highly porous materials, such as wood powder, plastic micro-particles, expanded pellets, or dry powders. Unlike traditional switches that may require larger contact areas or unstable triggering, the double-rod structure responds immediately upon initial contact, minimizing measurement blind spots.

From a process safety perspective, high sensitivity enhances early warning capabilities. In low-level detection, the instrument can recognize material approaching the lower limit early, allowing sufficient time for refilling or interlock control, preventing empty-running equipment, pneumatic transport anomalies, or production interruptions. In high-level alarms, signals are output before materials reach dangerous heights, reducing overflow risks and avoiding environmental contamination, material waste, or equipment damage.

Higher sensitivity also improves adaptability under challenging conditions. In silos experiencing vibration, discharge impacts, or density fluctuations, stable and repeatable triggering is critical. Optimized probe structure and signal logic ensure clear trigger thresholds, reducing false signals and drift, improving continuous operation reliability of automation systems.

3. Higher Reliability and Reduced False Alarms

In industrial automation, long-term stable operation often matters more than single performance parameters. Field conditions are complex, with material impact, density fluctuations, mechanical vibration, and temperature/humidity changes, all potentially affecting detection. Devices that consistently output clear and repeatable signals are crucial for uninterrupted production.

Double-rod structures optimize vibration transmission, producing stable and identifiable signals upon contact, with clear trigger boundaries. This reduces false alarms and prevents frequent unplanned starts/stops or process interruptions due to erroneous interlock signals. Long-term, this lowers maintenance costs, improves overall efficiency, and strengthens automation system reliability.

4. Anti-Adhesion for Complex Media

Many solid materials are adhesive, such as wet powders or oil-containing particles, prone to accumulation on probes.

Double-rod switches feature high anti-adhesion redundancy, maintaining stable measurement even in the presence of attachments.

This is particularly beneficial for:

- Sticky powders

- Easily caked materials

- High-humidity environments

5. Outstanding High-Temperature Resistance

High-temperature silos or processes can challenge conventional level switches.

Double-rod vibrating rod level switches support:

- Process temperatures up to 250℃

- Ultra-high temperature versions (air-cooled/water-cooled) up to 400℃

This meets requirements in metallurgy, building materials, and power industries.

6. Strong Corrosion Resistance

The instrument is made of 316L, 318S13, and other corrosion-resistant materials, effectively resisting chemical medium corrosion, offering:

- Longer service life

- Reduced replacement frequency

- Enhanced long-term stability

Ideal for corrosive powder environments.

7. Self-Diagnostic Function for Maintenance Efficiency

Modern industry emphasizes maintainability.

Double-rod switches feature advanced self-diagnostics, enabling rapid fault identification, helping maintenance personnel:

- Quickly assess issues

- Reduce troubleshooting time

- Improve repair efficiency

Thus lowering overall operation and maintenance costs.

8. Easy Installation, Plug-and-Play

The instrument requires no complex calibration and can be used immediately after installation, providing:

- Shorter construction time

- Reduced commissioning complexity

Highly suitable for retrofit projects.

9. Multiple Explosion-Proof Certifications

In environments with combustible gases or dust, safety is paramount.

Double-rod switches have achieved:

- CE certification

- Gas and dust dual explosion protection (Ex db IIC T1…T6 Gb; Ex tb IIIC T80℃…T440°C Db; Ex ia II CT1…T6 Ga; Ex ia IIIC T200100℃…T200450℃ Da)

Suitable for various hazardous areas.

10. Flexible Cable Design for Deep Silo Measurement

For deep containers like large silos or tall hoppers, extended probes are critical. Rope-type structures allow precise extension of detection points, enhancing measurement depth and range. Flexible cables absorb some mechanical stress from material impacts or discharge disturbances, reducing fatigue and wear from rigid connections, extending service life, and improving long-term stability. This design is also suitable for water sediment detection; even in solid-liquid mixtures, the probe maintains reliable vibration response and stable signal output.

4. Typical Applications

Double-rod vibrating rod level switches are primarily used for point-level detection of granular or powdered solids, including:

- High-level alarms

- Low-level protection

- Overflow control

- Empty-silo alarms

In industrial automation, they serve as critical interlock signal sources, providing timely feedback to control systems, ensuring equipment safety, continuous production, and reducing overflow, empty-silo, or unplanned downtime risks.

5. Development of Domestic Double-Rod Vibrating Rod Level Switches

Shenzhen Jiwei Automation’s Tube-11 double-rod vibrating rod level switch is the first domestic stick-type vibrating rod switch adopting a double-rod structure. It holds 3 invention patents (ZL201510009538.3, ZL201510059187.7, ZL201610511184.7) and 11 utility model patents.

The product uses piezoelectric devices for vibration drive and detection, achieving industry-leading performance, high reliability, and suitability for most granular material applications.

As industrial automation advances, high-reliability, low-maintenance detection devices are increasingly preferred by enterprises.

Conclusion

In summary, double-rod vibrating rod level switches optimize vibration response mechanisms through structural innovation. Compared with traditional single-rod designs, they excel in sensitivity, reliability, anti-adhesion, and high-temperature adaptability.

For industrial enterprises seeking stable operation and long-term cost control, selecting the right level measurement solution is not only a technical decision but also a critical factor for operational efficiency.

As industrial environments become increasingly complex, the demand for instrument stability continues to rise, and double-rod vibrating rod level switches are expected to play an essential role in more critical applications.