Common Flange Connection Types for Level Switches: Design Differences, Selection Tips, and Safety Considerations

In industrial automation measurement systems, level switches play a critical role in safety monitoring and process control. The reliability of their installation directly affects the long-term stable operation of industrial equipment. Among various installation methods, flanged connections have become one of the most widely used process connection forms for medium- and high-pressure applications, thanks to their excellent sealing performance and mechanical strength.

Compared with threaded connections and clamp connections, flanged connections provide higher structural rigidity and more stable sealing performance. They are particularly suitable for the following applications:

- Closed vessels

- Pressurized storage tanks

- High-temperature media environments

- Flammable and explosive processes

- Storage systems for corrosive liquids

However, during equipment selection, many engineers focus only on whether a flanged connection is used, while overlooking the significant differences among various flange structures in terms of pressure rating, vibration resistance, sealing reliability, and maintenance cost. Incorrect flange selection may increase the risk of leakage and, in severe cases, lead to safety incidents.

This article systematically analyzes the five most common flange connection types used with level switches and provides selection recommendations based on engineering practice.

1. Basic Types of Flange Sealing Faces

Before understanding flange structures, it is essential to recognize the sealing face types, as the sealing face directly determines leakage control performance.

Common sealing face types include:

1. Raised Face (RF)

The most widely used sealing form in industrial applications. Sealing is achieved by gasket compression and is suitable for medium-pressure environments.

2. Male and Female Face (MFM)

This design improves alignment through male–female engagement, reducing gasket displacement and offering better sealing stability than RF faces.

3. Tongue and Groove Face (TG)

Provides stronger mechanical positioning and is well suited for high-temperature applications.

4. Ring Joint Face (RJ)

Uses metal ring gaskets and is designed for high-pressure sealing, commonly applied in harsh environments such as oil and gas industries.

Engineering Note:

The sealing face rating often has a greater impact on final sealing performance than whether a flanged connection is used.

2. Detailed Explanation of Five Common Flange Connection Types

1. Slip-On Flange

Slip-on flanges, also known as flat welding flanges, are installed by inserting the pipe into the flange bore and applying fillet welds.

Structural Characteristics

- Lower manufacturing cost

- Easy installation

- Lower welding precision requirements

Limitations

Due to the presence of two weld seams, fatigue resistance is relatively limited. Under continuous vibration or thermal cycling, the welded areas may become potential weak points.

Recommended Applications

- Atmospheric or low-pressure storage tanks

- Cooling water systems

- General process pipelines

Not recommended for: High-vibration or high-impact pressure applications.

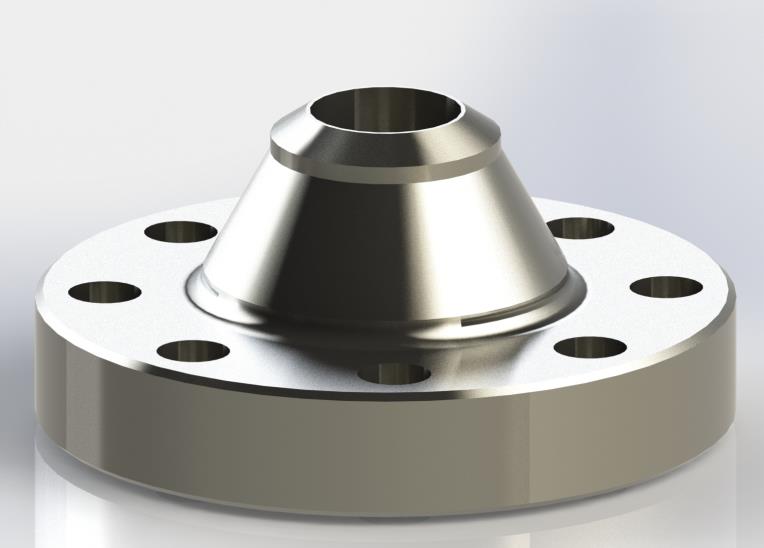

2. Weld Neck Flange

Weld neck flanges are widely regarded as one of the strongest flange connection types.

Core Advantages

The tapered neck structure provides a smooth transition from pipe to flange, significantly reducing stress concentration.

This results in:

- Higher fatigue resistance

- Better bending strength

- Higher pressure-bearing capacity

Typical Applications

- High-pressure reactors

- Petrochemical installations

- Steam systems

- High-temperature pipelines

In many critical installations, weld neck flanges are considered the preferred solution for long-term operation.

3. Threaded Flange

Threaded flanges connect directly to pipes via internal threads, eliminating the need for welding.

Key Advantage: Easy Installation

Particularly suitable for:

- Areas where hot work is prohibited

- Retrofit projects

- Temporary installations

Risk Factors

Threaded connections rely on mechanical sealing and may develop micro-gaps over time due to temperature fluctuations.

Therefore, they are generally recommended to:

- Avoid applications with severe pressure or temperature fluctuations

- Be used cautiously in hazardous media systems

They are typically more suitable for low- to medium-pressure conditions.

4. Socket Weld Flange

Socket weld flanges secure the pipe by inserting it into a socket and applying fillet welding.

Technical Characteristics

- High concentricity after welding

- Stable sealing performance

- Higher strength than slip-on flanges

They perform particularly well in small-diameter, high-pressure systems.

Installation Consideration

To prevent additional stress caused by thermal expansion, a small gap is usually reserved during installation.

5. Lap Joint Flange

Lap joint flanges consist of a flange ring combined with a stub end.

Key Value: Balance of Economy and Corrosion Resistance

The wetted parts can be made from high-grade corrosion-resistant materials, while the outer flange ring uses lower-grade materials, effectively reducing overall cost.

Typical Applications

- Strongly corrosive media

- Equipment requiring frequent disassembly

However, due to lower overall rigidity, lap joint flanges are not recommended for applications involving high mechanical loads.

3. Why Flange Selection Is Especially Critical for Level Switches

In closed vessel applications, level switches are not merely measuring devices—their installation points often form part of the pressure boundary system. Once the process connection or structural integrity fails, it may not only affect measurement reliability but also compromise the vessel’s safety boundary, leading to serious engineering and safety risks.

In actual operation, failure of the connection structure may result in consequences such as toxic media leakage, sudden discharge of high-temperature liquids or steam, and dispersion of flammable or explosive gases in confined spaces. These incidents are often sudden, wide-ranging, and difficult to predict, with amplified hazards in enclosed or restricted environments.

Therefore, during the selection of level switches and their process connections, a comprehensive system-level safety assessment should be conducted, with particular attention to the following aspects:

- Whether the rated pressure of the process connection provides sufficient safety margin beyond normal operating conditions

- Whether frequent or rapid temperature changes exist, which may cause fatigue damage due to thermal stress

- Whether the equipment operates continuously for long periods or experiences frequent start-stop cycles

- Whether the installation area is classified as a hazardous area or involves hazardous media, requiring higher sealing and safety standards

Engineering experience shows that in critical process units and key measurement points, selecting equipment based solely on the lowest initial purchase cost often results in higher lifecycle costs and increased safety risks. Rational selection should prioritize long-term reliability and system safety.

4. Engineering Selection Recommendations

From a long-term reliability perspective, the following general guidelines may be considered:

- High pressure / high temperature:

→ Weld neck flange preferred - Small-diameter high-pressure systems:

→ Socket weld flange recommended - General industrial applications:

→ Slip-on flange usually sufficient - Environments where welding is prohibited:

→ Threaded flange offers advantages - Strongly corrosive systems:

→ Lap joint flange provides better economic efficiency

There is no “universally best” flange—only the option that best matches the specific application conditions.

5. A Commonly Overlooked Fact

Many industrial field cases reveal that leakage issues often do not originate from the instrument itself but are closely related to the process connection. Improper connection design may lead to local stress concentration and micro-cracks under long-term pressure and thermal cycling; insufficient installation quality may result in uneven bolt preload or damaged sealing components; and incorrect sealing face selection may create hidden leakage points during later operation.

From a safety engineering perspective, the process connection is far more than a simple mechanical interface—it is a critical part of pressure system integrity. Its design and execution quality largely determine whether equipment can operate reliably over the long term under complex conditions. Therefore, during instrument selection and system design, process connections should be evaluated as part of the overall safety strategy, reducing operational risks at the source through appropriate structural design, sealing solutions, and installation practices.

In other words, the process connection itself is an integral part of safety design and should never be underestimated.

Conclusion

As industrial facilities continue to grow in scale and operating parameters, the reliability requirements for level measurement devices are steadily increasing. As the critical interface between instruments and vessels, flanged connections affect not only installation quality but also the intrinsic safety of the entire system.

In engineering practice, understanding the structural differences and application boundaries of various flange types is often more important than focusing solely on instrument performance.

Correct flange selection is, in essence, the first safety barrier for reliable system operation.