Systematic Analysis of Level Switch Failures——Field-Based Engineering Experience and Practical Insights

In industrial applications, level switches are often regarded as simple in structure, highly reliable, and instruments that can be “installed and used immediately.” However, in actual operation, issues such as false alarms, missed alarms, and frequent replacement of level switches are far from uncommon.

In many cases, on-site feedback is ultimately reduced to a single conclusion:

“The level switch has failed.”

Based on extensive engineering practice, however, true failures are often not caused by defects in the instrument itself. Instead, they originate from insufficient understanding of process conditions, incorrect selection assumptions, improper installation, or mismatches between the instrument and the control system.

This article starts from common on-site problems and provides a systematic analysis of level switch failures, helping engineers establish a more rational and reliable diagnostic approach.

1. Clarifying a Common Misconception:

A Level Switch Is Not a “Universal Switch”

The fundamental function of a level switch is to detect changes in material state based on specific physical principles.

Whether it is a tuning fork, vibrating rod, rotary paddle, RF admittance, or capacitive level switch, each technology relies on one of the following assumptions:

- Damping effect of the material on vibration

- Mechanical torque exerted by the material

- Changes in electrical parameters caused by the material

Once actual operating conditions deviate from these underlying assumptions, situations easily arise where the instrument logic is correct, but the output result is wrong.

Therefore, before analyzing a suspected failure, the first step should not be powering up the instrument for testing, but rather revisiting the actual process conditions.

2. The Most Common “Pseudo-Failures”:

False Alarms and Delayed Alarms

2.1 Typical Causes of False Alarms

False alarms typically manifest as frequent high-level signals even though the vessel is clearly not full. Common on-site causes include:

Material buildup or coating

In humid powders, sticky granules, or high-fat-content materials, a persistent layer can form on the probe surface, causing the instrument to interpret material presence incorrectly.

Unstable material flow behavior

During filling or discharging, short-term material impact on the probe may cause momentary triggering.

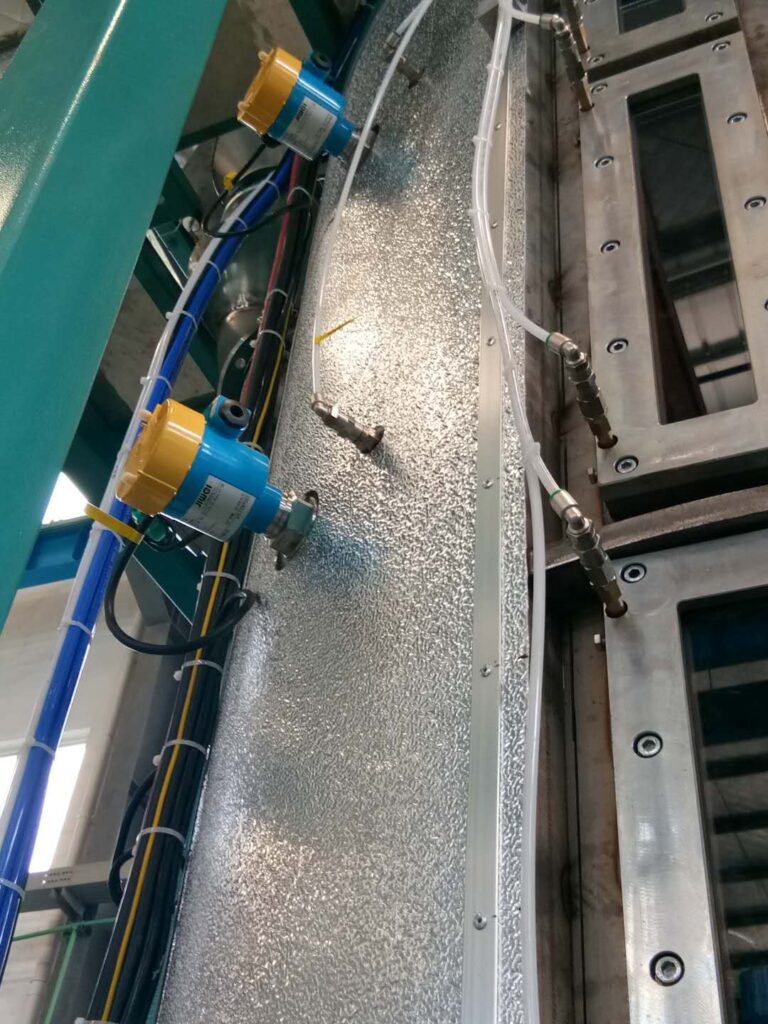

Improper installation position

When the probe is installed directly below the inlet, it is exposed to material impact and localized accumulation, resulting in unstable signals.

In these cases, the instrument itself is not damaged. Instead, the probe continuously operates in a borderline detection state.

2.2 Delayed Alarms Are Not Simply “Slow Response”

Another common issue is delayed switching: the material level has already reached the detection point, yet the output does not change promptly. This is often misinterpreted as insufficient sensitivity, while the actual reasons are more complex:

- Low-density or loosely packed materials exert insufficient force on vibrating or mechanical sensing elements

- Internal voids or bridging within the material cause intermittent or incomplete contact

- The probe is installed in a non-representative level zone, such as a dead zone or recirculation area

In such cases, simply increasing sensitivity rarely provides a reliable solution. A reassessment of material flow patterns and accumulation behavior is usually required.

3. Electrical Issues:

Frequently Overlooked but Highly Influential

In many installations, the mechanical structure and sensing element of the level switch function normally, yet abnormal signals persist. The root cause often lies in the electrical system.

3.1 Power Supply and Wiring Problems

Common electrical issues include:

- Voltage fluctuations exceeding the allowable operating range

- Loose terminal connections causing intermittent signal loss

- Strong interference sources in the control cabinet (such as variable frequency drives or high-power contactors) without proper isolation

These issues are often difficult to reproduce during standalone instrument testing, but repeatedly occur during integrated system operation.

3.2 Misinterpretation of Output Logic

Many sites treat level switches as simple digital devices, overlooking critical details such as:

- Mismatch between normally open / normally closed logic and PLC program logic

- Alarm delay and de-energized state behavior not fully considered

- Failure to apply fail-safe principles in safety interlocks

As a result, the instrument operates correctly, but the control system interprets the signal incorrectly.

4. Environmental Factors:

Not Limited to “Extreme Conditions”

It is commonly believed that level switches only encounter problems in extreme environments such as high temperature, high pressure, or strong corrosion. In reality, gradual environmental factors in seemingly normal conditions can be equally destructive:

- Long-term high humidity leading to moisture ingress into electronic modules

- Cyclic temperature changes causing condensation inside the terminal housing

- Progressive dust penetration reducing insulation performance

Such issues rarely appear as sudden failures. Instead, performance gradually degrades until problems become concentrated and visible.

5. Establishing a More Reliable Diagnostic Path

In practical engineering work, repeatedly replacing instruments is far less effective than establishing a structured troubleshooting logic:

- Review process changes: Has the material changed? Has the process been modified?

- Inspect installation conditions: Is the probe covered, displaced, or contaminated?

- Verify the electrical system: Are power supply, grounding, and signal paths stable?

- Only then suspect the instrument itself

Extensive field data show that failures caused by manufacturing defects account for a much smaller proportion than commonly assumed.

Conclusion:

Reliability Comes from System Understanding, Not Single-Point Expectations

The value of a level switch does not lie solely in whether it can detect material presence, but in whether it is correctly understood and properly applied.

When failure analysis moves beyond the simplistic conclusion of “instrument failure” and instead evaluates process conditions, installation, electrical integration, and system logic as a whole, many seemingly complex problems become clear and controllable.

This systemic understanding is the true foundation for the long-term reliable operation of level switches in industrial environments.