Will Humans Be Replaced by Automation? ——Radar and Industrial Intelligence

With the rapid development of smart manufacturing and industrial automation, the question “Will humans be replaced by automation?” has become a hot topic both within the industry and among the public. From fully automated production lines in large factories to intelligent warehouse logistics, more and more traditional roles are being taken over by robots, automated control systems, and smart instruments. However, the reality is more nuanced than simple “replacement.”

For example, the 80GHz radar level meter not only demonstrates the power of industrial automation technology but also highlights the necessity and value of human-machine collaboration in modern factories.

1. Radar Level Meters: Core Assistants in Automation

Non-contact Measurement: High-Precision Replacement of Manual Work

Traditional level measurement often relies on manual inspection or mechanical floats, which is time-consuming, labor-intensive, and carries significant safety risks. In chemical storage tanks, for instance, manual inspection of acidic or flammable materials is highly hazardous. Radar level meters enable continuous, non-contact measurement without human intervention. Even under high temperature, high pressure, or corrosive environments, they provide precise level readings, reducing both risk and operational errors.

Smart Algorithms for Complex Conditions

Modern radar level meters, such as the Jiwei JWrada® 80GHz series, feature proprietary smart echo-learning algorithms. These algorithms accurately differentiate real level signals from interference such as foam, steam, and dust. This ensures stable measurement even in extreme conditions where traditional instruments fail, reducing the likelihood of human misjudgment.

Data Integration and Remote Monitoring

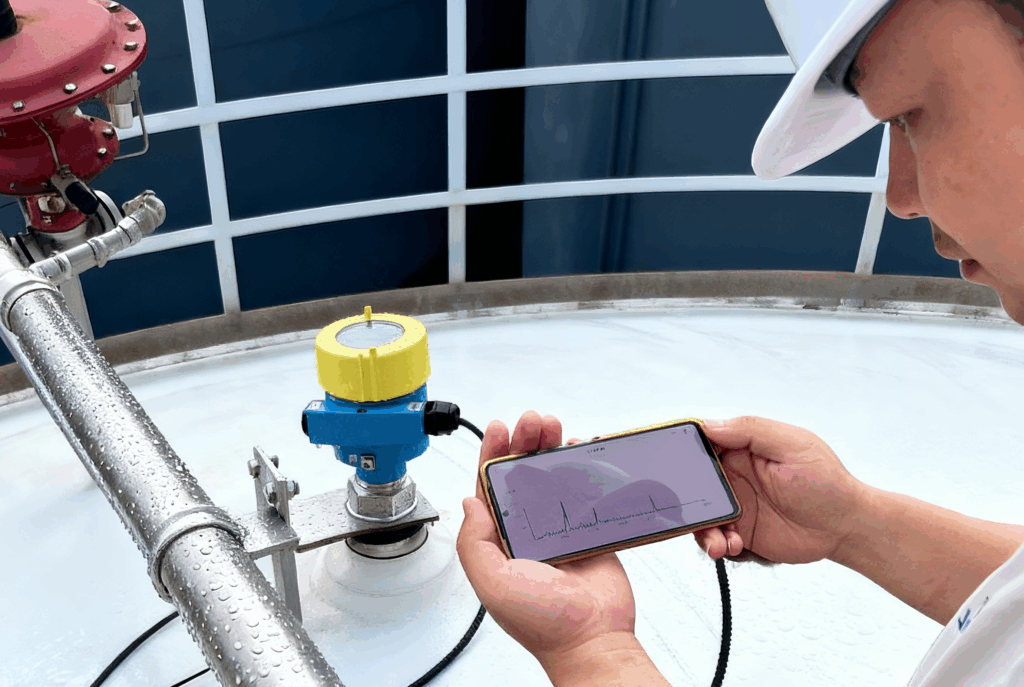

Radar level meters can seamlessly integrate with DCS, PLC, and SCADA systems, enabling real-time data collection and remote monitoring. Combined with Industrial IoT (IIoT) platforms, operators can monitor multiple tank levels, historical data, and alarm events via mobile or desktop devices, facilitating predictive maintenance. This approach not only reduces manual inspection but also makes plant management more intelligent and human-centric.

2. Automation Enhances Human Value, Rather Than Fully Replacing It

Risk Reduction and Efficiency Improvement

Intelligent radar level meters replace manual inspection in high-risk storage tanks, but operators are not eliminated—they are freed from repetitive and hazardous tasks. This allows them to focus on safety management, production scheduling, and process optimization.

Technology as an Enabler, Not a Complete Replacement

Although radar level meters provide automatic alarms and real-time measurements, industrial environments still require human expertise. For example, when abnormal signals or equipment anomalies occur, operators analyze the data, evaluate process conditions, and determine corrective actions. Automation serves as a decision-support tool, rather than fully replacing human judgment.

Skill Upgrade and Job Transformation

With the widespread adoption of radar level meters, smart sensors, and IIoT, job requirements are shifting from “manual inspection” to operating intelligent systems, analyzing data, and performing predictive maintenance. Workers need to acquire more digital skills while benefiting from safer and higher-value work.

3. Industry Applications of Radar Level Meters

Chemical Industry

In acidic liquid storage tanks, JWrada® radar level meters enable continuous monitoring, automatic alarms, and remote management. Manual daily inspections are greatly reduced, enhancing both production safety and management efficiency.

Food and Beverage Industry

In chocolate or coconut juice tanks, foam interference often causes inaccurate measurements with traditional level instruments. 80GHz radar level meters leverage smart echo recognition to achieve high-precision level control while complying with food hygiene standards. Operators are freed from repetitive liquid-level checks and can focus on optimizing production processes.

Metallurgy and Cement Industry

High-dust material silos pose challenges for conventional level instruments. Radar level meters, with strong anti-interference capability, deliver stable long-term measurement, replacing manual monitoring and improving both production continuity and safety.

4. Automation Trends and the Role of Radar Level Meters

High-Frequency and Smart Technology

As industrial processes become more complex, 80GHz and higher radar level meters have become the industry trend. High frequency combined with intelligent algorithms significantly improves measurement reliability under conditions like steam, foam, and dust.

Proprietary Software and Iterative Upgrades

Sustainable software updates and remote upgrades are core competencies of modern radar level meters. For instance, Jiwei JWrada® has a proprietary software platform that can be continuously updated, ensuring long-term technological leadership.

Digitalization and Industrial Connectivity

Data from radar level meters can integrate with industrial cloud platforms, enabling remote operations and intelligent factory construction. Data visualization and analysis improve decision-making efficiency and reduce human intervention.

Fast Delivery and Localized Service

Domestic radar level meter manufacturers provide nationwide service networks with same-day response and next-day on-site support, ensuring production continuity and maintenance efficiency. This is a differentiating advantage over international brands in local service.

Domestic Replacement Trend

As domestic high-performance radar level meter technology matures, companies like Jiwei Automations are increasingly chosen to replace high-end products from VEGA and Endress+Hauser (E+H). This ensures high reliability and measurement accuracy while offering better cost-effectiveness and response speed.

5. Conclusion: Humans Will Not Be Fully Replaced

- Human-Machine Collaboration is Key: Radar level meters automate repetitive and hazardous tasks, but humans still lead decision-making and optimization.

- Technology Liberates Productivity: Industrial automation, powered by smart instruments, IIoT, and AI, frees labor from repetitive tasks and improves efficiency and safety.

- Skill Upgrade and Job Transformation: Operating intelligent systems, analyzing data, and maintaining equipment become essential skills in modern industrial roles.

Overall, automation does not eliminate human roles but liberates people from repetitive and dangerous work, increasing the value of their positions. Radar level meters and other smart sensors have become indispensable tools in industrial automation, driving modern factories toward smart, efficient, and safe operations.