Jiwei Intelligent Radar Level Meter: Non-Contact High-Precision Measurement

Introduction

In modern industrial transportation and storage tank monitoring, real-time, reliable, and precise measurement of material levels has become increasingly critical. Particularly in logistics, oil, chemical, and food industries, maintaining stable monitoring under harsh operating conditions and ensuring low maintenance are key factors in equipment selection. Intelligent radar level meters, with their advanced technology and high adaptability, are becoming the preferred solution across these sectors.

What is an Intelligent Radar Level Meter?

The Jiwei PRO series intelligent radar level meter is a level measurement instrument based on radar technology (microwave/millimeter-wave) that accurately measures the height of liquids, solids, or slurries in tanks, containers, or silos. Typically installed at the top of the container, it emits radar waves and receives reflected signals to determine the material surface location precisely. Its non-contact design avoids direct contact with the material, reducing wear, corrosion, and maintenance costs, while delivering stable measurements even in challenging environments with foam, dust, adhesion, or turbulence.

Operating Principle Overview

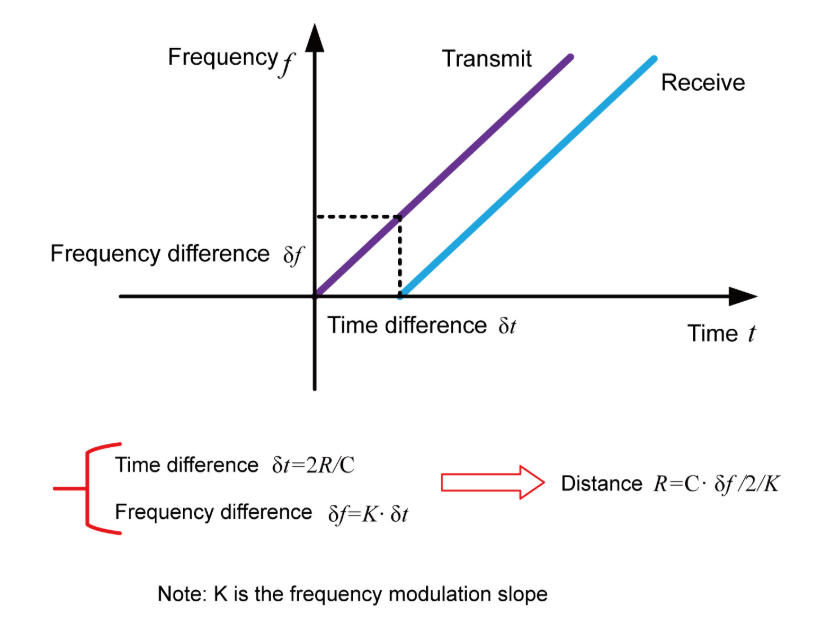

Intelligent radar level meters generally use Frequency Modulated Continuous Wave (FM-CW or FMCW) technology. The instrument emits a continuous radar signal with a changing frequency toward the material surface. When the signal is reflected back, the frequency difference (δf) between the transmitted and received signal is proportional to the distance (R) from the radar to the material surface.

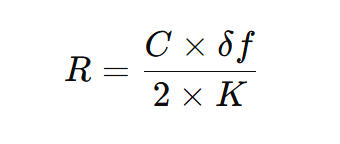

The distance can be calculated using the formula:

where C is the speed of light (electromagnetic wave propagation in air), and K is the slope of the frequency modulation. Using this method, the actual distance from the installation point to the material surface is calculated, and combined with the known tank height, the material level can be determined.

Key advantages of this technology include:

- Continuous-wave operation ensures stable signals with strong noise resistance.

- Superior performance in dynamic, foamy, or dusty environments compared to traditional pulse measurement methods.

Main Features and Technical Advantages

Based on the above principle, the Jiwei PRO series intelligent radar level meters provide the following key advantages:

- Millimeter-wave design for high-precision measurement: Some models offer ±1 mm accuracy with no blind zones.

- Compact antenna and narrow beam angle: Concentrated energy and stronger echo signals improve reliability in complex tanks or silos.

- Strong penetrability: Works reliably even with surface adhesion, condensation, or low dielectric materials.

- Wide dynamic signal range: Ensures stable measurement of low dielectric constant media, such as lightweight liquids or granular solids.

- Fast response: Rapid measurement mode reacts in less than 1 second for dynamic process conditions.

- Versatile communication interfaces: Compatible with IO-Link, RS-485 (e.g., Modbus RTU), and other industrial protocols for seamless system integration.

- Software upgrades and intelligent functions: Supports Bluetooth 5.4 wireless connection and the latest software system for remote maintenance, parameter adjustment, and firmware updates, enhancing measurement performance and operational efficiency without on-site intervention.

Applications

The Jiwei intelligent radar level meters are widely used across various industrial scenarios, including:

- Liquid level monitoring in tanks and containers (e.g., oil, chemical liquids, food liquid raw materials)

- Solid material level measurement in silos and hoppers

- Slurry monitoring in mining and wastewater treatment processes

- Raw material storage and liquid blending monitoring in food and beverage processing

- High-temperature, high-pressure, steam, or foamy environments in chemical and pharmaceutical industries

Installation and Wiring Requirements

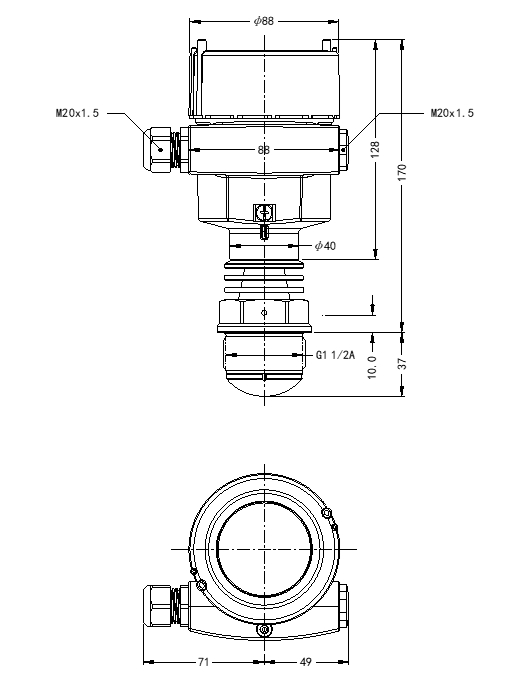

To ensure high-precision, stable, and reliable measurements in actual applications, proper installation and wiring are essential. Installation methods include threaded (G½″, NPT 1½″), flange (DN40 or larger), or hoisting, selected based on the site conditions. Consider tank or silo dimensions, shape, inlet/outlet positions, and surrounding structures to prevent radar signal interference.

For flange installations, maintain a minimum distance of 200 mm between the meter and the tank wall to avoid reflection interference. Avoid positioning the meter directly above material inlets, agitators, flow guides, or other structures that could reflect radar waves.

Wiring must follow specific requirements. Two-wire (4–20 mA) systems share power and signal lines, while four- or six-wire systems require separate power supply and are recommended to use shielded cables to reduce electromagnetic interference. For RS-485 communication output, use six-core shielded cables separating power, analog, and digital lines to ensure stable signal transmission and measurement accuracy. Following these guidelines allows radar level meters to deliver high precision, fast response, and long-term reliability in complex conditions.

Applications in Transportation and Logistics

In the transportation industry, especially in tank trucks, liquid tank trailers, and bulk solid transport vehicles, the high reliability and low-maintenance features of intelligent radar level meters are particularly important. The instruments provide real-time monitoring during loading and unloading, support remote monitoring and upgrades, reduce human reading errors, lower maintenance costs, and improve operational efficiency. Non-contact measurement reduces wear and downtime, making them ideal for mobile and vibration-prone environments.

Conclusion

With non-contact measurement, high precision, strong adaptability, and versatile communication capabilities, intelligent radar level meters have become the preferred solution for modern industrial liquid and solid level monitoring. Whether in tanks, silos, or during transportation and material handling, they provide stable, controllable, and low-maintenance measurement solutions. Proper selection, installation, and system integration can further enhance production safety, operational efficiency, and overall industrial intelligence.