Jiwei Automations: Smart, High-Reliability Industrial Level Instrumentation Solutions

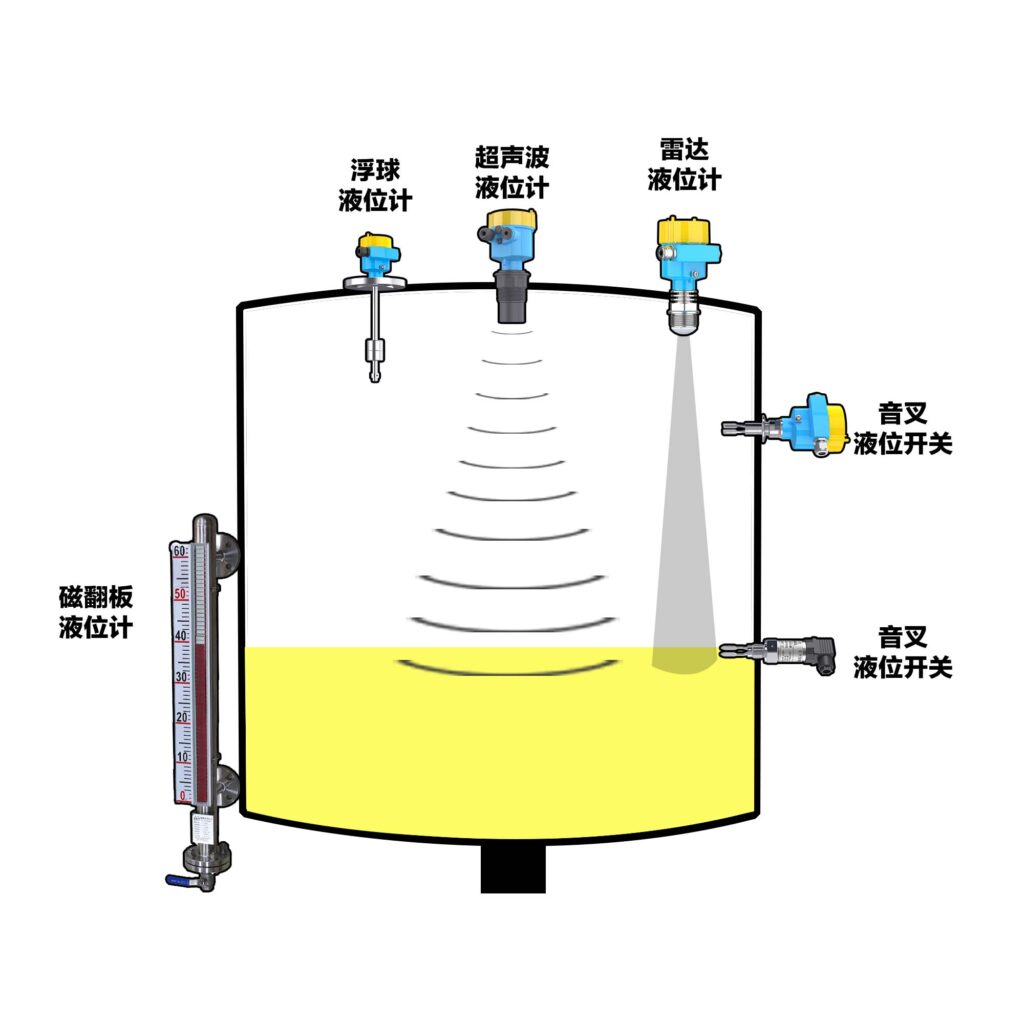

In modern industrial production, level instrumentation has become a crucial component for ensuring safety management, production efficiency, and cost control. Whether monitoring liquids, slurries, powders, or bulk materials, precise and reliable level measurement is essential to maintain stable and safe operations. As a national high-tech enterprise, Jiwei Automations provides a complete range of level instrumentation solutions, from continuous measurement to point-level alarms, covering radar, vibrating rod, tuning fork, RF admittance, and rotary paddle technologies. Our solutions are independently developed by Jiwei Automations, delivering smart, high-reliability, and industrial-grade monitoring for complex applications.

Challenges in Industrial Level Instrumentation

Industrial environments often present extreme conditions, including high temperatures and pressures, heavy dust, corrosive liquids or slurries, steam, and foam interference. Additionally, variations in material types—liquids, slurries, powders, and bulk solids—affect continuous measurement accuracy and point-level alarm reliability. Continuous 24/7 production requires instruments that are highly stable, low-maintenance, and compliant with explosion-proof, corrosion-resistant, and other safety standards. Combining high-precision continuous level instrumentation with reliable point-level switches and intelligent monitoring systems is essential to ensure safe production, optimize efficiency, and reduce operational risks.

Continuous Level Measurement — JWrada® Radar Level Meter

JWrada® radar level meters are high-end continuous measurement instruments independently developed by Jiwei Automations, utilizing 80GHz FMCW radar technology to provide stable measurements in dust, steam, corrosive liquids, and high-temperature/high-pressure conditions.

JWrada® Advantages

- Sub-millimeter resolution: High-performance chips and proprietary algorithms enable precise detection of small level changes.

- Non-contact measurement: The probe avoids direct contact with materials, preventing wear, adhesion, and cleaning issues.

- Intelligent echo processing: Proprietary software identifies foam, dust, and steam interference to ensure stable output.

- Digital interface: Supports HART and Modbus protocols, seamlessly integrating with DCS/SCADA systems.

- Bluetooth setup and remote diagnostics: Jiwei Smart Control App enables rapid calibration, configuration, and real-time data analysis.

- Independently designed and manufactured: Custom-molded compact casing, refined through 55 processing steps, combining durability and aesthetics, showcasing Jiwei’s innovation.

Typical Applications:

- High-dust environments like grain, flour, and sugar silos

- Chemical tanks, corrosive liquid tanks, and mixing vessels

- Large cement silos and fly ash storage

- Buffer silos and material handling systems

Point-Level Alarm — Tube-11 Vibrating Rod Level Switch

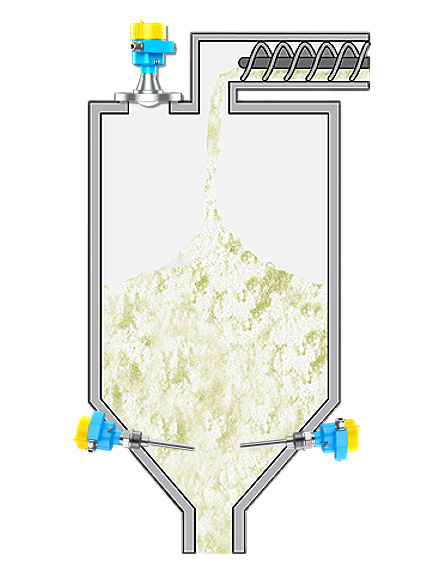

While continuous measurement monitors the full range, critical points still require alarms. Tube-11 vibrating rod level switches provide high-reliability point-level detection for powder and bulk material silos.

Tube-11 Key Features

- Dual-rod design: Durable, resistant to heavy dust, high humidity, and mechanical impact.

- Accurate upper/lower limit alarms: Detect ultra-low density materials (ρ ≥ 0.02 g/cm³) to prevent overfilling or empty silo conditions.

- Maintenance-free: Smooth rods minimize material buildup, ensuring stable operation even in high-humidity or sticky materials.

- High-temperature tolerance & cooling technology: Operates in up to 400 °C environments using advanced water-cooling to extend lifespan.

- Explosion-proof safety certification: Suitable for ethanol, chemical, and high-risk environments. First in China to match or exceed imported product performance.

Tuning Fork Series — Ring-11 and Fork-11

Jiwei’s tuning fork series offers point-level detection for both liquids and solids, ideal for rapid alarm and limit control.

Ring-11 Liquid Level Switch

- Designed for liquids: Corrosive, food-grade, or chemical liquids.

- Multiple output modes: Supports DPDT and SPST for rapid alarms and flexible control system integration.

- Hygienic design: Clamp-polished Ra < 0.5 μm, NAMUR output optional, first in China to achieve this combination.

- Custom lengths: Up to 6 meters for large tanks and special processes.

- High-temperature version: Up to 400 °C available for extreme applications.

- SIL certification: Recognized by the National Certification and Accreditation Administration (CNCA), distinguishing real certification from market fakes.

Fork-11 Powder/Bulk Material Switch

- Suitable for powders and granules: Reliable limit detection for bulk materials.

- Dual-rod design: Enhanced anti-interference for dust, airflow, and vibration.

- High-temperature and corrosion-resistant options: Ideal for chemical and high-temperature powder silos.

- Ultra-low density sensitivity: Down to 0.008 g/cm³, exceeding E+H standard parameters.

- Durable construction: 316L stainless steel fork body, resistant to corrosion and impact.

Independently developed by Jiwei Automations, performance can replace VEGA and other high-end imports.

RF Admittance and Rotary Paddle Level Switches

- RF Admittance: Suitable for powders, fly ash, and bulk solids; LED indicator; optional 450 °C ultra-high-temperature version for reliable point-level alarms.

- Rotary Paddle: Compact, simple, wear-resistant design for bulk material silos; equipped with ultra-long-life motor, suitable for high-dust, high-impact environments.

These switches can be combined with JWrada® radar meters for dual continuous and point-level monitoring, ensuring safe operation in complex conditions.

Multi-Industry Applications

Ethanol Production:

Buffer silos for crushed grain use JWrada® radar meters for continuous measurement, while Tube-11 and Fork-11 ensure upper/lower limit alarms, maintaining stability under dust and high-speed material discharge.

Food & Beverage:

Sugar, milk, and flour silos use Ring-11 tuning fork switches and JWrada® radar meters for continuous monitoring and reliable point-level alarms, improving safety and efficiency.

Chemical & Petrochemical:

Corrosive liquids, slurries, and high-temperature tanks are monitored with JWrada® radar meters, RF admittance, and vibrating rod switches to ensure safe operation under extreme conditions.

Cement & Powder Storage:

Large silos and bulk material warehouses use JWrada® radar meters to penetrate dust for continuous measurement; rotary paddle and Tube-11 switches provide overflow protection and reliable alarms, reducing manual inspection and improving efficiency.

Advantages of Intelligent Level Instrumentation

- Enhanced safety: Continuous measurement + point-level alarms + explosion-proof design.

- Cost efficiency: Reduced downtime and maintenance, higher production efficiency.

- Ease of operation: Bluetooth configuration, remote monitoring, and automated data collection.

- High reliability: Resistant to dust, steam, foam, corrosion, high temperatures, and impact.

- Independent innovation: Performance comparable to imported brands, fast delivery, and robust technical support.

Case Study — Ethanol Plant & Food Powder Warehouse, Henan

- Stable continuous measurement: JWrada® radar meters maintain accuracy under dust and foam interference.

- Reliable point-level alarms: Tube-11, Fork-11, Ring-11 ensure upper/lower limit detection.

- Reduced maintenance: Less manual inspection and lower operational risk.

- Intelligent management: Real-time data integrated into DCS for automated material scheduling and inventory management.

Feedback shows improved safety, efficiency, and reliability, achieving domestic replacement of imported instruments.

Conclusion

Modern industrial level instrumentation requires not only measurement but also intelligence, reliability, and safety. Jiwei Automations offers a complete solution:

- Continuous measurement: JWrada® radar level meters

- Point-level alarms: Tube-11 vibrating rod switches; Ring-11 and Fork-11 tuning fork switches; RF admittance and rotary paddle switches

- Smart operation: Bluetooth setup, remote monitoring, and DCS integration